5132210-UIM-H-0916

12

Johnson Controls Unitary Products

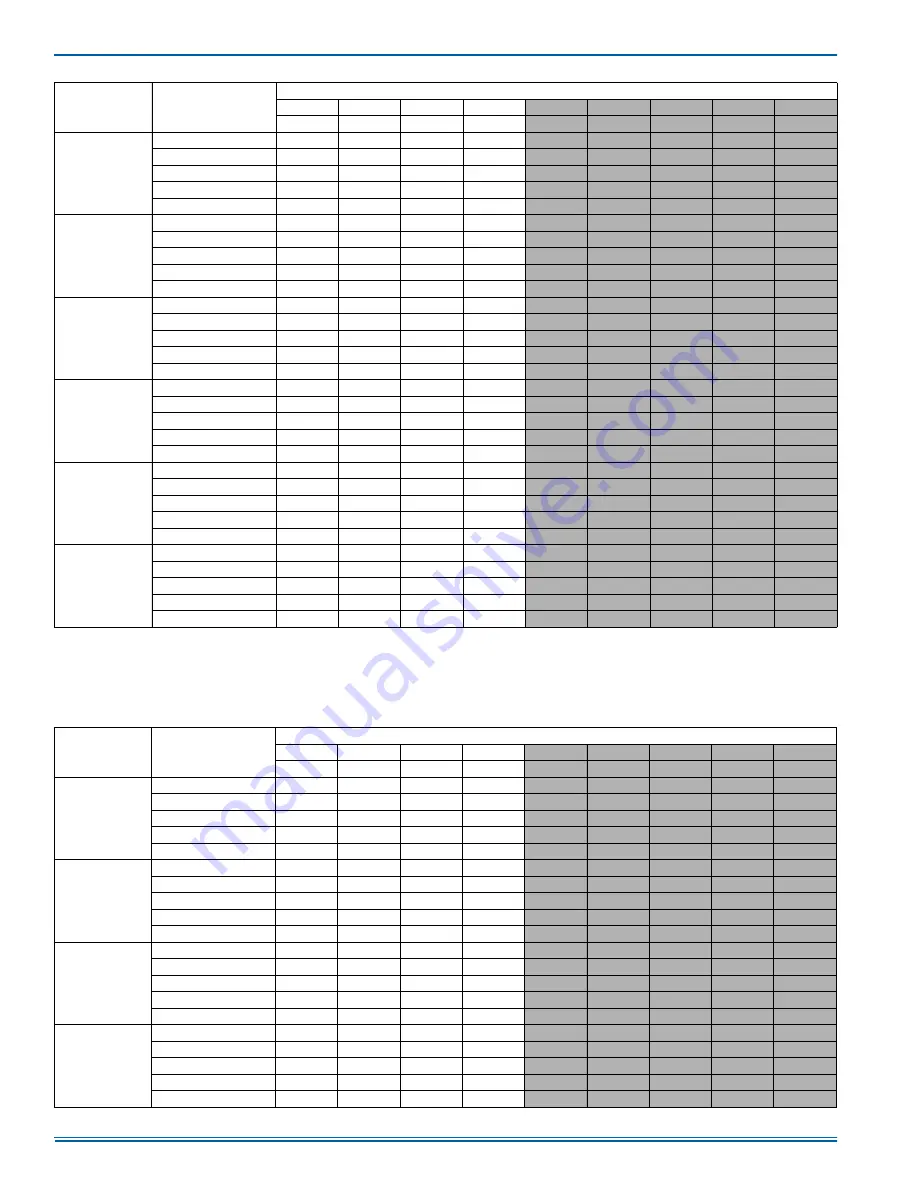

1. Airflow tested with dry coil conditions, without air filters, at 230 volts

2. Applications above 0.8" w.c. external static pressure are not recommended.

3. Brushless DC high efficiency standard ECM blower motor used for all indoor blower assemblies.

4. Minimal variations in airflow performance data results from operating at 208 volts. Data above may be used in those cases.

5. Heating applications tested at 0.50" w.c. esp, and cooling applications tested at 0.30" w.c.esp per standards.

48065

Low (1)

1046

1009

980

946

915

878

844

779

649

Low/Medium (2)

1295

1250

1213

1172

1133

1087

1045

964

802

Medium (3)

1620

1564

1517

1466

1418

1360

1308

1206

1002

Medium/High (4)

1798

1722

1669

1620

1572

1527

1480

1413

1280

High (5)

2146

2085

2025

1960

1872

1862

1798

1735

1609

48100

Low (1)

1620

1564

1517

1466

1418

1360

1308

1206

1002

Low/Medium (2)

1694

1630

1580

1530

1482

1430

1380

1292

1116

Medium (3)

1798

1722

1669

1620

1572

1527

1480

1413

1280

Medium/High (4)

1835

1758

1703

1653

1604

1558

1511

1442

1304

High (5)

2146

2085

2025

1960

1872

1862

1798

1735

1609

48125

Low (1)

1620

1564

1517

1466

1418

1360

1308

1206

1002

Low/Medium (2)

1798

1722

1669

1620

1572

1527

1480

1413

1280

Medium (3)

1922

1863

1804

1754

1724

1658

1612

1559

1453

Medium/High (4)

2001

1952

1890

1839

1820

1742

1696

1651

1561

High (5)

2146

2085

2025

1960

1872

1862

1798

1735

1609

60065

Low (1)

1073

1043

1009

988

963

941

917

892

842

Low/Medium (2)

1329

1292

1250

1223

1192

1165

1136

1105

1043

Medium (3)

2054

1998

1934

1890

1843

1801

1757

1710

1616

Medium/High (4)

2195

2144

2098

2049

2003

1955

1883

1868

1838

High (5)

2445

2388

2306

2293

2235

2178

2129

2077

1973

60100

Low (1)

1730

1682

1628

1592

1552

1517

1479

1439

1359

Low/Medium (2)

1858

1807

1749

1710

1667

1629

1589

1546

1460

Medium (3)

2054

1998

1934

1890

1843

1801

1757

1710

1616

Medium/High (4)

2195

2144

2098

2049

2003

1955

1883

1868

1838

High (5)

2445

2388

2306

2293

2235

2178

2129

2077

1973

60125

Low (1)

2063

2008

1943

1899

1851

1809

1763

1717

1625

Low/Medium (2)

2130

2084

2032

1983

1927

1951

1860

1815

1725

Medium (3)

2195

2144

2098

2049

2003

1955

1883

1868

1838

Medium/High (4)

2275

2252

2169

2154

2112

2065

1989

1976

1950

High (5)

2445

2388

2306

2293

2235

2178

2129

2077

1973

Table 12:

Airflow Performance - Side Duct Application (Continued)

Model

Motor Speed

External Static Pressure (Inches WC)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

1.0

SCFM

SCFM

SCFM

SCFM

SCFM

SCFM

SCFM

SCFM

SCFM

Table 13:

Airflow Performance - Bottom Duct Application

Model

Motor Speed

External Static Pressure (Inches WC)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

1.0

SCFM

SCFM

SCFM

SCFM

SCFM

SCFM

SCFM

SCFM

SCFM

24050

Low (1)

754

710

665

611

560

491

445

391

283

Low/Medium (2)

867

815

773

720

677

622

559

505

397

Medium (3)

951

908

868

828

781

735

686

631

521

Medium/High (4)

1024

982

942

902

861

817

775

721

613

High (5)

1204

1159

1121

1085

1051

1013

975

938

864

24075

Low (1)

899

869

827

782

734

685

630

575

465

Low/Medium (2)

1033

960

924

879

834

787

735

685

585

Medium (3)

1186

1133

1095

1056

1016

975

935

891

803

Medium/High (4)

1357

1322

1284

1248

1211

1174

1127

1087

1007

High (5)

1480

1439

1404

1367

1369

1299

1264

1226

1150

30050

Low (1)

726

676

622

575

520

467

410

376

308

Low/Medium (2)

928

886

841

795

745

706

658

607

505

Medium (3)

1021

983

942

900

855

811

770

729

647

Medium/High (4)

1109

1071

1029

995

949

908

864

826

750

High (5)

1170

1134

1096

1061

1020

978

938

899

821

30075

Low (1)

1076

1042

1009

969

930

890

849

808

726

Low/Medium (2)

1104

1063

1025

987

947

908

869

830

752

Medium (3)

1205

1170

1136

1098

1060

1025

985

943

859

Medium/High (4)

1285

1251

1213

1179

1141

1104

1065

1027

951

High (5)

1406

1375

1341

1306

1271

1236

1198

1163

1093

Continued on next page.