5132210-UIM-H-0916

18

Johnson Controls Unitary Products

Adjust as follows:

1.

Remove the cap from the valve body. See Figure 10 for location.

2.

To decrease the gas pressure, turn the adjusting screw counter-

clockwise.

3.

To increase the gas pressure, turn the adjusting screw clockwise.

Adjustment of Temperature Rise

After about 20 minutes of operation, determine the furnace temperature

rise. Take readings of both the return air and the heated air in the ducts

about six feet from the furnace where they will not be affected by radi-

ant heat.

The temperature rise (or temperature difference between the return air

and the heated air from the furnace) must lie within the range shown on

the rating plate and the data in Table 6.

After the temperature rise has been determined, the CFM can be calcu-

lated as follows:

Direct Drive Blower

All units have direct drive, multi speed standard ECM blower motors.

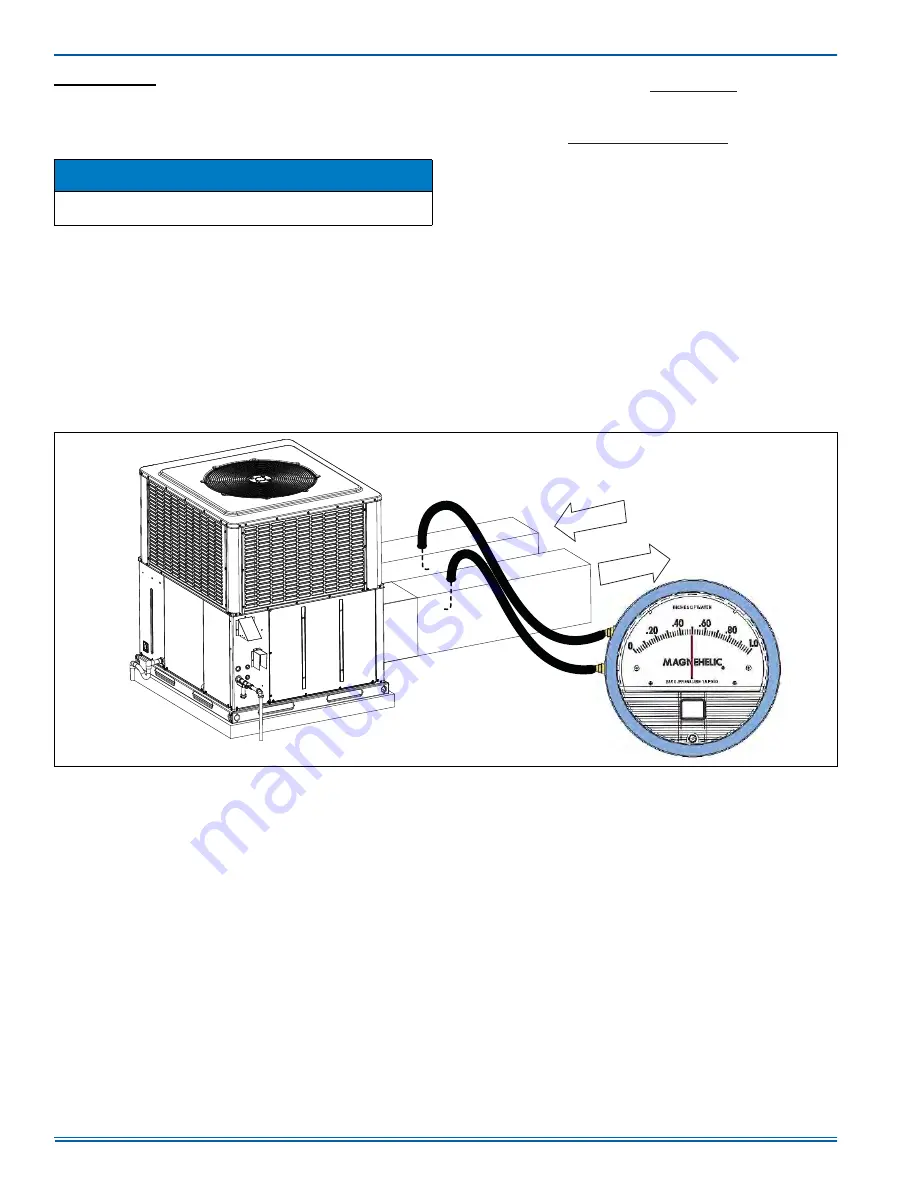

EXTERNAL STATIC PRESSURE SETUP

To measure external static pressure:

• Measure the supply air static pressure

• Record this positive number

• Measure the return air static pressure

• Record this negative number

• Treat the negative number as a positive and add the two numbers

together

• This is total system static

NOTICE

The correct manifold pressure for natural gas furnaces is 3.5 IWG.

The correct manifold pressure for propane (LP) is 10.0 IWG.

BTUH Output

1.08 x CFM

OR

CFM =

BTUH Output

Degrees F Temp Rise =

1.08 x Degrees F Temp Rise

FIGURE 11:

Measuring External Static Pressure

A0435-001

RETURN AIR

DUCT

SUPPLY AIR

DUCT