5132210-UIM-H-0916

Johnson Controls Unitary Products

21

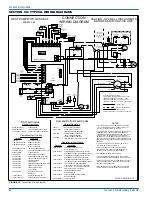

FIGURE 13:

Ladder Wiring Diagram

BLU 36

RED 35

WHT 32

GRN 31

Y

R

G

C

THERMOSTAT

USE COPPER

CONDUCTORS

ONLY

RED/GRN 51

ORG 52

RED 49

GRN 4

ID_FAN

(LOW)

(LOW/MED)

(MED)

(MED/HIGH)

(HIGH)

RED/BLK 50

ROLLOUT

PRESSURE

LIMIT

BLOWER

DELAY

60

90

120

180

FS

L1

IND

SPARK

TRANSFORMER

M

230V

C

L

G

N

1

2

3

4

5

1

1

2

3

4

DRAFT

MOTOR

YEL 53

YEL 53

GRN 54

ORG 52

4

5

6

1

2

3

7

8

9

3

2

1

24V COM

Y SPD

G SPD

W SPD

R

O

Y

W

C

BRN

YEL

WHT 39

CONTROL BOARD SETTINGS:

COMBUSTION BLOWER POST PURGE: 60 SEC

INDOOR BLOWER HEAT ON DELAY: 30 SEC

INDOOR BLOWER COOL OFF DELAY: 60 SEC

INDOOR BLOWER HEAT OFF DELAY: FIELD SELECT

W

Y

O

R

G

C

LOW

VOLTAGE

BOX

RED 40

ORG

IGNITOR

FLAME

SENSOR

GAS

VALVE

DSI

CONTROL

CAP

W

(COOLING SPEED)

(HEATING SPEED)

(CONTINUOUS FAN)

BLK

BRN

RED

BRN/WHT 13

BLK 6

RED 9

OD_FAN

POWER SUPPLY

208/230-1-60

PUR 1

BLK 5

1

230-1-60

COM

PRI

24V SEC

40 VA

208V

230V

1

COMPR

C

S

R

230-1-60

L1

T1

T2

L2

FAN

HERM

C

DUAL

CAPACITOR

RED 7

GRN

GND

SINGLE POLE

CONTACTOR

BLU 43

PUR 2

YEL 33

GRN 44

LINE VOLTAGE

FIELD INSTALLED POWER

LOW VOLTAGE

FIELD INSTALLED CONTROL

5

4

3

2

6

1

BLK

BRN

GRN 10

RED

LOSS OF CHARGE

CRANKCASE

HEATER

WHT 17

BLU 16

BLU 16

BRN 21

WHT 17

RV RVG C M

HPS

COIL AMBIENT

BLU 22

YEL 23

BRN 21

4

3

2

1

COND. FAN RELAY

COIL

SENSOR

AMBIENT

SENSOR

REVERSING

VALVE

SOLENOID

CONTACTOR

COIL

DEFROST CONTROL

DEFROST SETTING

LPS

HI PRESS

R

O Y W

C

W out

GRN

LT BLU 20

LT BLU 20

YEL 19

YEL 19

O/B

ORG 34

BLK/WHT 8

BLK/WHT 12

BLK 25

RED 26

ORG 27

YEL 28

WHT/GRY 29

YEL 44

RED 46

WHT 47

RED 56

BLU 55

PUR 38

BLK

BLK

TEMPERATURE

SWITCH

OPTIONAL CRANKCASE HEATER

BLK

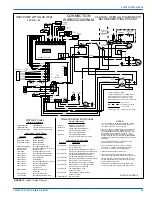

HEAT PUMP WITH GAS HEAT

208/230-1-60

CONNECTION

WIRING DIAGRAM

CAUTION - OPEN ALL DISCONNECTS

BEFORE SERVICING THIS UNIT

Demand Defrost Fault Codes

Flashes

Condition

10 RED FLASHES

9 RED FLASHES

8 RED FLASHES

7 RED FLASHES

6 RED FLASHES

5 RED FLASHES

4 RED FLASHES

3 RED FLASHES

2 RED FLASHES

HIGH-PRESSURE SWITCH FAULT

(NOT IN LOCKOUT YET )

SYSTEM IN HIGH-PRESSURE SWITCH LOCKOUT

(LAST MODE OF OPERATION WAS NORMAL COMPR.)

SYSTEM IN HIGH-PRESSURE SWITCH LOCKOUT

(LAST MODE OF OPERATION WAS DEFROST)

SYSTEM IN LOW-PRESSURE SWITCH LOCKOUT

(LAST MODE OF OPERATION WAS NORMAL COMPR.)

LOW VOLTAGE (<19.2 VAC) PREVENTING

FURTHER RELAY OUTPUTS FOR > 2 SECONDS

LOW VOLTAGE (< 16 VAC) STOPPED CURRENT

RELAY OUTPUTS FOR > 2 SECONDS

LIQUID LINE SENSOR FAILURE

(OPEN OR SHORTED)

OUTDOOR AMBIENT SENSOR FAILURE

(OPEN OR SHORTED)

CONTROL FAILURE

1. ALL FIELD WIRING TO BE ACCOMPLISHED FOLLOWING

CITY, LOCAL AND/OR NATIONAL CODES IN EFFECT AT

THE TIME OF INSTALLATION OF THE UNIT.

2. CAUTION : LABEL ALL WIRES PRIOR TO DISCONNECTION

WHEN SERVICING CONTROLS. WIRING ERRORS CAN

CAUSE IMPROPER AND DANGEROUS OPERATION. IF ANY

OF THE WIRING, AS SUPPLIED WITH THE UNIT, MUST

BE REMOVED, IT MUST BE REPLACED WITH TYPE 105 C.

600 VOLT WIRE OR EQUIVALENT CLEARLY RENUMBERED

FOR IDENTIFICATION. VERIFY PROPER OPERATION AFTER

SERVICING.

3. THE THERMOSTAT/CONTROL CONNECTED TO THIS

UNIT MUST BE DUAL FUEL CAPABLE.

4. FACTORY WIRED FOR 230 VOLT SUPPLY POWER.

FOR 208 VOLT, MOVE BLACK WIRES FROM THE 230

TO THE 208 VOLT TAP ON THE TRANSFORMER.

5. MOTORS ARE INHERENTLY PROTECTED.

6. SEE UNIT NAMEPLATE FOR MAXIMUM FUSE AND/OR

CIRCUIT BREAKER SIZE AND MINIMUM CIRCUIT AMPACITY.

7. SELECT COOLING (YELLOW) BLOWER SPEED THAT WILL

DELIVER APPROXIMATELY 400 CFM/TON FOR COOLING

AND HEAT PUMP OPERATION.

8. BLOWER MOTOR SPEED CONNECTIONS SHOWN ARE

TYPICAL, BUT MAY VARY BY MODEL AND APPLICATION.

NOTES:

DSI Fault Codes

Flashes

Operational Fault Codes

Condition

LAMP OFF

SLOW GREEN FLASHES

SLOW AMBER FLASHES

RAPID AMBER FLASHES

4 AMBER FLASHES

STEADY ON RED

1 RED FLASH

2 RED FLASHES

3 RED FLASHES

4 RED FLASHES

5 RED FLASHES

6 RED FLASHES

7 RED FLASHES

8 RED FLASHES

9 RED FLASHES

10 RED FLASHES

11 RED FLASHES

Normal Operation

STANDBY MODE

CALL FOR FURNACE HEAT ACTIVE

CONTROL IN FACTORY TEST MODE

GREEN HEARTBEAT

AMBER HEARTBEAT

RAPID GREEN FLASHES

NO POWER TO CONTROL

NORMAL OPERATION

NORMAL OPERATION

(WITH CALL FOR HEAT)

LOW FLAME SENSE CURRENT

NO G FROM THERMOSTAT WITH Y CALL

CONTROL FAILURE

FLAME PRESENT WITH GAS OFF

CHECK PRESSURE SWITCH WIRING

VENT OR TERMINATION PROBLEM

AIRFLOW PROBLEM

FLAME ROLLOUT

REPEATED PRESSURE SWITCH CYCLES

FAILED TO LIGHT BURNERS

LOSS OF FLAME DURING

CALL FOR HEAT

INCORRECT POLARITY OR

NO NEUTRAL

GAS VALVE SHORTED "ON"

CHECK BLOWER MOTOR/WIRING

NO POWER TO THE CONTROL

COMPR. OPERATION ACTIVE

(COMPR. CONTACTOR ENERGIZED)

CONTROL NORMAL OPERATION

(NO CALL FOR COMPRESSOR)

CONTROL NORMAL OPERATION

ASCD (ANTI SHORT CYCLE DELAY) ACTIVE

LAMP OFF

STEADY RED

SLOW RED

RAPID RED

Normal Operation

Operational Fault Codes

BLK

WHT

5133413-UWD-B-0716