5132210-UIM-H-0916

4

Johnson Controls Unitary Products

LOCATION

Use the following guidelines to select a suitable location for these units:

1.

Unit is designed for

outdoor installation

only.

2.

Condenser coils must have an unlimited supply of air. Where a

choice of location is possible, position the unit on either north or

east side of building.

3.

Suitable for mounting on roof curb.

4.

For ground level installation, a level pad or slab should be used.

The thickness and size of the pad or slab used should meet local

codes and unit weight. Do not tie the slab to the building foundation.

5.

Roof structures must be able to support the weight of the unit and

its options/accessories. Unit must be installed on a solid, level roof

curb or appropriate angle iron frame.

6.

Maintain level tolerance to 1/8” across the entire width and length of

unit.

CLEARANCES

All units require particular clearances for proper operation and service.

Installer must make provisions for adequate combustion and ventilation

air in accordance with section 5.3 of Air for Combustion and Ventilation

of the National Fuel Gas Code, ANSI Z223.1 – Latest Edition (in

U.S.A.), or Sections 7.2, 7.3, or 7.4 of Gas Installation Codes, CSA-

B149.1 (in Canada) - Latest Edition, and/or applicable provisions of the

local building codes. Refer to Table 4 for clearances required for com-

bustible construction, servicing, and proper unit operation.

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove any packaging until

the unit is near the place of installation. Rig the unit by attaching chain

or cable slings to the lifting holes provided in the base rails. Spreader

bars, whose length exceeds the largest dimension across the unit,

MUST

be used across the top of the unit.

Units may be moved or lifted with a forklift. Slotted openings in the base

rails are provided for this purpose.

WARNING

Do not attach supply and return duct work to the bottom of the unit

base pan as the drain pan could be compromised.

WARNING

Excessive exposure of this furnace to contaminated combustion air

may result in equipment damage or personal injury. Typical contami-

nates include: permanent wave solution, chlorinated waxes and

cleaners, chlorine based swimming pool chemicals, water softening

chemicals, carbon tetrachloride, Halogen type refrigerants, cleaning

solvents (e.g. perchloroethylene), printing inks, paint removers, var-

nishes, hydrochloric acid, cements and glues, antistatic fabric soften-

ers for clothes dryers, masonry acid washing materials.

WARNING

Do not permit overhanging structures or shrubs to obstruct con-

denser air discharge outlet, combustion air inlet or vent outlets.

!

!

!

CAUTION

Before lifting, make sure the unit weight is distributed equally on the

rigging cables so it will lift evenly.

CAUTION

If a unit is to be installed on a roof curb other than a Unitary Products

roof curb, gasket or sealant must be applied to all surfaces that come

in contact with the unit underside.

CAUTION

All panels must be secured in place when the unit is lifted.

The condenser coils should be protected from rigging cable damage

with plywood or other suitable material.

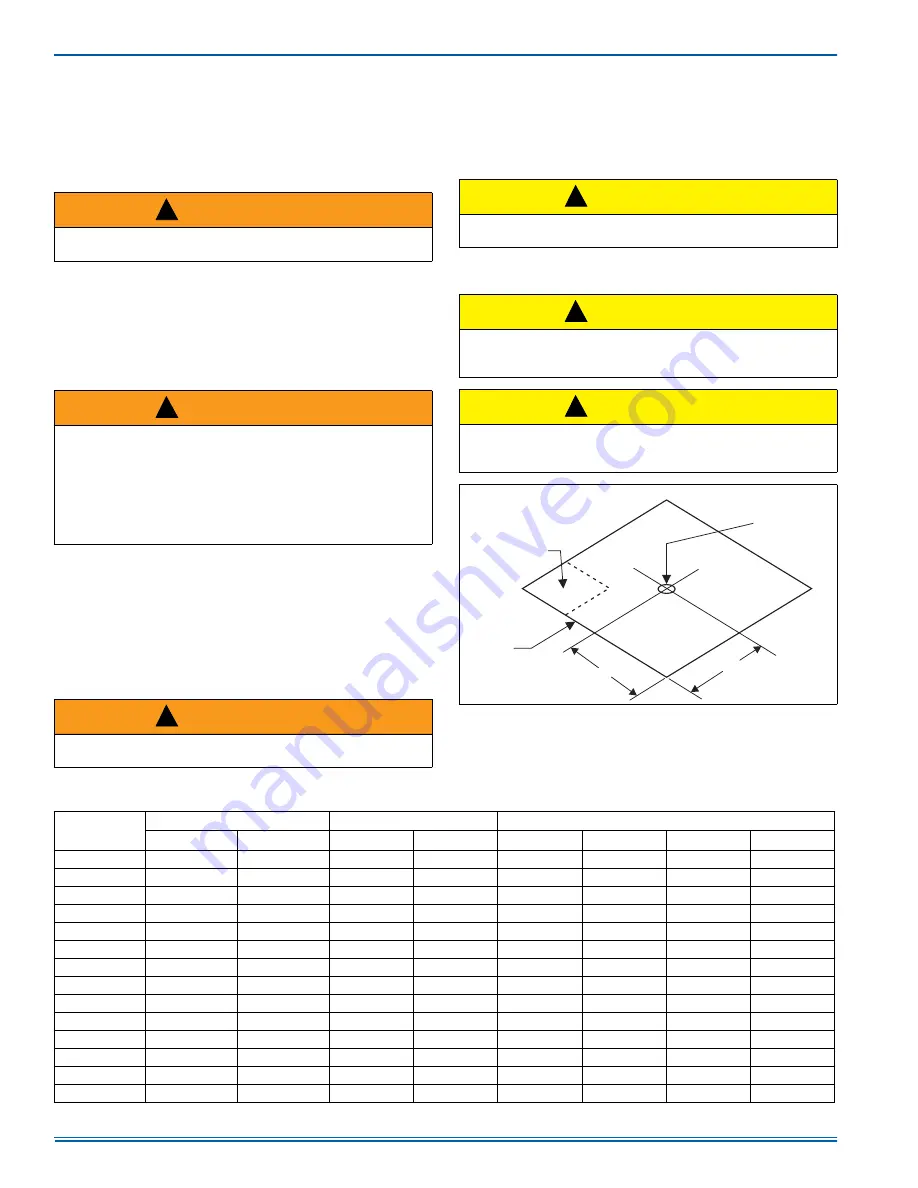

FIGURE 2:

Unit 4 Point Load Weight

!

!

!

X

CENTER OF

GRAVITY

FRONT

OF UNIT

Y

"D"

"C"

"B"

"A"

A0295-001

COMPRESSOR

Table 2:

Weights and Dimensions

Model

Weight (lbs.)

Center of Gravity

4 Point Load Location (lbs.)

Shipping

Operating

X

Y

A

B

C

D

24050

399

394

28

15

131

101

86

76

24075

409

404

28

15

135

103

86

80

30050

454

449

28

15

155

108

96

90

30075

458

453

28

15

161

102

90

100

36065

503

498

29

14

176

122

104

96

36100

510

505

29

14

178

123

109

95

42065

537

532

29

14

190

132

112

98

42100

539

534

29

14

191

133

109

101

48065

556

551

28

14

199

137

106

109

48100

564

559

28

14

194

141

117

107

48125

569

564

29

14

193

146

126

99

60065

582

577

29

14

199

151

127

100

60100

586

581

28

14

201

152

123

105

60125

593

588

27

15

202

151

125

110