035-17311-002-A-0803

16

Unitary Products Group

Note orientation. Panel is “insulation” side up.

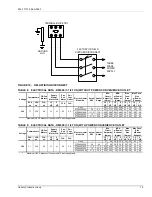

CONDENSATE DRAIN

The side condensate drain is reversible and maybe re-ori-

ented to the rear of the cabinet to facilitate condensate pip-

ing. A condensate drain connection is available through the

base pan for piping inside the roof curb. Trap the connection

per Figure 16. The trap and drain lines should be protected

from freezing.

Plumbing must conform to local codes. Use a sealing com-

pound on male pipe threads. Install condensate drain line

from the 3/4 inch NPT female connection on the unit to an

open drain.

COMPRESSORS

The compressors are mounted on elastomer insulators. The

mounting bolts have been fully tightened for shipping.

FILTERS

Two-inch filters are supplied with each unit. One-inch filters

may be used with no modification to the filter racks. Filters

must always be installed ahead of evaporator coil and must

be kept clean or replaced with same size and type. Dirty fil-

ters reduce the capacity of the unit and result in frosted coils

or safety shutdown. All units use four (4) 20”x25”x2” filters.

The unit should not be operated without filters properly

installed.

When fastening ductwork to side duct flanges on

unit, insert screws through duct flanges only. DO

NOT insert screws through casing. Outdoor duct-

work must be insulated and water-proofed.

FIGURE 13 - SIDE PANELS WITH HOLE PLUGS

FIGURE 14 - RETURN DOWNFLOW PLENUM WITH

PANEL

FIGURE 15 - DISCHARGE PANEL IN PLACE

FIGURE 16 - CONDENSATE DRAIN

Do not loosen the compressor mounting bolts.

Make sure that panel latches are properly positioned

on the unit to maintain an airtight seal.

O P T I O N A L C O I L

G U A R D

3 " M i n i m u m