035-19671-002 Rev. A (0704)

Unitary Products Group

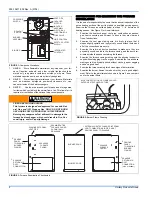

11

ITEM

DESCRIPTION

MOTOR

1*

MOTOR,DIRECT DRIVE BLOWER

2

MOTOR,VENTOR ASS’Y.

ELECTRICAL

3

CAPACITOR, RUN

4

CONTROL, HIGH LIMIT

5

CONTROL,FURNACE [FC]

6

IGNITER

7

SENSOR, FLAME

8

SWITCH, AIR PRESSURE [1LP]

9

SWITCH, DOOR [SW]

10*

TRANSFORMER

11

VALVE, GAS

12

SWITCH, FLAME ROLL-OUT

[ROS 3]

12A

CONTROL,Flame Roll Out

(2ea.)[ROS1,2]

13

CONTROL, AUX. LIMIT

(2 ea.),LS2,LS3]-

14*

FUSE (ATO 3)

15

AIR MOVING

16

HOUSING, BLOWER

17

WHEEL, BLOWER

FABRICATED PARTS

18

SHIELD, SECONDARY AIR

19*

BAFFLE, FLUE

20

BURNER, MAIN GAS

21

BRACKET, IGNITOR

22

DECK, BLOWER (Rear)

23

DECK, FRONT

24

HEAT EXCHANGER ASS’Y

25

MANIFOLD, GAS

26

PANEL. UPPER ACCESS

27

PAN, BASE

28

PANEL, BLOWER ACCESS

29

PANEL, TOP

30

WRAPPER, INSULATED

31

CHANNEL, TOE PLATE

32

BRACKET, TOP DOOR

33

BRACKET, BOTTOM DOOR

34*

RACK, FILTER

35

FRAME, SIDE BASE (2 Req’d)

36

BRACKET, ROLL-OUT SWITCH

37

ORIFICE, BURNER (Natural #45)

38

PLATE, RESTRICTOR

39

COLLAR, FLUE

40*

LO-NOX SCREEN

(L Models only)

MISCELLANEOUS

41*

FILTER (.75 x 16 x 25)

42

SIGHT GLASS, OVAL

43

GASKET, RESTRICTOR PLATE

44

TUBING, SILICONE

45

46*

DIAGRAM, WIRING

47*

HARNESS, MAIN WIRING

48*

ISOLATOR, TUBE (3 Req’d.)

49*

ISOLATOR, WASHER (3 Req’d.)

50*

ISOLATOR,SLEEVE (3 Req’d.)

51*

MOUNT, MOTOR

52*

GROMMET, 1/2” DIA.

53

DOOR KNOB

54*

RETAINER, DOOR KNOB

55*

NUT, SELF THREADING

56*

RETAINER, SQUARE

ITEM

DESCRIPTION

NOTE:

*Not Shown

Major components and suggested stocking items are shown with shaded item number.