035-19671-002 Rev. A (0704)

6

Unitary Products Group

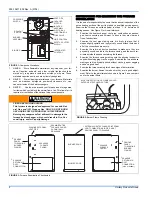

1.

Remove six mounting screws that hold the vent motor to the

restrictor plate. The surface is gasketed and gasket can be reused

if it is carefully removed. It is necessary to remove this assembly to

gain access to the restrictor plate mounting holes. The assembly

may be vacuumed if cleaning is necessary. If any vent assembly

parts are damaged, replace with an entire new assembly (except

for gaskets).

2.

Remove the perimeter screws attaching the restrictor plate assem-

bly to the vestibule panel. The surface is also gasketed. The

assembly, including the flue baffle plate (rear) may be vacuumed

or cleaned with hot water if necessary.

3.

The upper portion of the heat exchanger is now accessible. With a

long flexible wire brush, clean inside each tube at both the top and

bottom. The brush must pass around the rear heat exchanger

tubes. Vacuum loose scale and dirt from each tube.

4.

Clean - Replace all components in reverse order. Re-gasket all

surfaces which required a gasket. Reconnect all wiring. Reattach

vent pipe and gas supply lines before restoring service to furnace.

Restore electrical power, check gas supply piping for leaks, and

then verify furnace operation.

SEQUENCE OF OPERATION

The following describes the sequence of operation of the furnace. Refer

to Figure 1 for component location.

1.

Call for 1st stage only

• On a call for 1st stage heat, the thermostat closes a circuit

between R and W1.

• The Microprocessor in the Furnace Control runs a ‘Self Check’.

• The Control checks the Primary Limit, Auxiliary Limit, and Roll-

out Switches for closed contacts.

• The Control checks that the Low Fire Pressure Switch (1LP) is

open.

• The Inducer Motor is energized on high speed, closing the con-

tacts of 1LP.

• The Control checks that 1LP is closed.

• The Igniter is energized for 17 seconds.

• The Gas Valve is energized on 1st Stage (Low Fire).

• Flame Rectification is recognized within 7 seconds.

• The Inducer is switched to low speed.

• 30 seconds after flame is proven, the ‘Heat Low’ relay is ener-

gized providing 120 Volts AC to the Blower Motor.

• At the same time, the EAC and Hum relays are energized, pro-

viding 120 Volts AC to the EAC Hot and Hum terminals.

2.

Call for 2nd Stage after 1st Stage is operating

• A call for 2nd Stage can be made by a 2-Stage thermostat, or by

the W2 delay timer on the furnace control.

• The Inducer Motor is shifted to high speed by the control, closing

the contacts of 2LP (The High Fire Pressure Switch.).

• The Control checks that 2LP is closed.

• The Gas Valve is energized on 2nd Stage (High Fire).

• The Control simultaneously de-energizes the Heat Low relay

and energizes the Heat High relay, providing 120 Volts AC to a

different speed of the Blower Motor.

3.

2nd Stage is satisfied, 1st Stage still calling.

• If a Single Stage Thermostat is used, the Furnace will stay on

High Fire until the thermostat is satisfied.

• When the circuit between R and W2 is opened, the Control

switches the Inducer Motor to low speed, causing the contacts of

2LP to open.

• When 2LP opens, 2nd Stage of the Gas Valve is de-energized.

• 30 seconds later, the Control switches the Blower from Heat

High to Heat Low.

4.

1st Stage Satisfied

• The Thermostat opens the circuit between R and W1

• Immediately the Gas Valve is de-energized and Flame Rectifica-

tion is lost.

• The Inducer Motor is de-energized after a 15 second Post Purge

and the Hum terminal is de-energized.

• The ‘Fan Off Delay’ circuit is initiated. The Delay time can be

field set at 60, 90, 120, or 180 seconds. It comes from the fac-

tory set at 60 seconds.

• The Heat Low terminal is de-energized; stopping the Blower and

the EAC terminal is de-energized.

5.

1st and 2nd Stage called simultaneously

• The 1st stage call is processed as described in paragraph 1

above.

• Once Flame Rectification is established, 2nd Stage is entered

immediately as described in paragraph 2 above.

6.

1st and 2nd Stage satisfied simultaneously

• Both stages of the Gas Valve are de-energized.

• Flame Rectification is lost.

• The Inducer and Hum relays are de-energized after a 15-second

post purge.

• 30 seconds later the Control shifts the Blower from Heat High to

Heat Low.

• After the Blower-Off Delay Circuit is satisfied, the Blower and

EAC are de-energized.

7.

Manual Fan Operation

• With the thermostat in the Fan On position, a circuit is completed

between R and G of the Control.

• The Heat Low and EAC relays are energized by the Control.

8.

Call for Cooling

• The thermostat closes two circuits R to Y and R to G. Since the

Outdoor Unit is connected to Y and C at the Control, it is ener-

gized.

• The Cool and EAC relays are energized by the Control.

• A Blower-Off Delay Timing Circuit is energized by the call on Y.

9.

Cooling call satisfied

• The thermostat opens the R to Y and R to G circuits.

• The Outdoor Unit is de-energized.

• The 60-second, Blower-Off Delay, timing circuit is initiated.

• After 60 seconds, the Cool and EAC relays are de-energized.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and danger-

ous operation. Verify proper operation after servicing.