FORM 160.55-O1 (604)

129

YORK INTERNATIONAL

3. Compressor Drive Motor (See motor man u fac tur er’s

main te nance and service in struc tion sup plied with

unit)

a.Clean air passages and windings per

manufacturer’s in struc tions.

b. Meg motor wind ings - See Fig. 65 for de tails.

c. Relubricate ball bear ings.

Don’t over look motor drive end bear-

ing lo cat ed in mo tor support of F1, F2

com pres sors.

4. Purge unit.

a. Clean and in spect all valves.

b. Drain and

ß

ush purge shell.

c. Clean or i

Þ

c es.

5. Inspect and service elec tri cal com po nents as

necessary.

6. Perform chemical anal y sis of system.

Every Two Years

1. If unit is equipped with SSS or VSD,

ß

ush cool ing

circuit and replace with new coolant solution, YORK

Part # 013-02987-000.

NEED FOR PURGING THE SYSTEM

To assure sat is fac to ry operation, it is important that these

systems be kept free of moisture laden air and noncon-

densible gas es. Air in the system usually col lects in the

con dens er, blanketing some of the con dens ing surface,

causing the dis charge pressure and tem per a ture to rise,

re sult ing in high operating cost, and possibly surg ing, or

shut down of system by high pres sure cutout. Mois ture

in the system causes acid for ma tion which is de struc tive

to internal system parts.

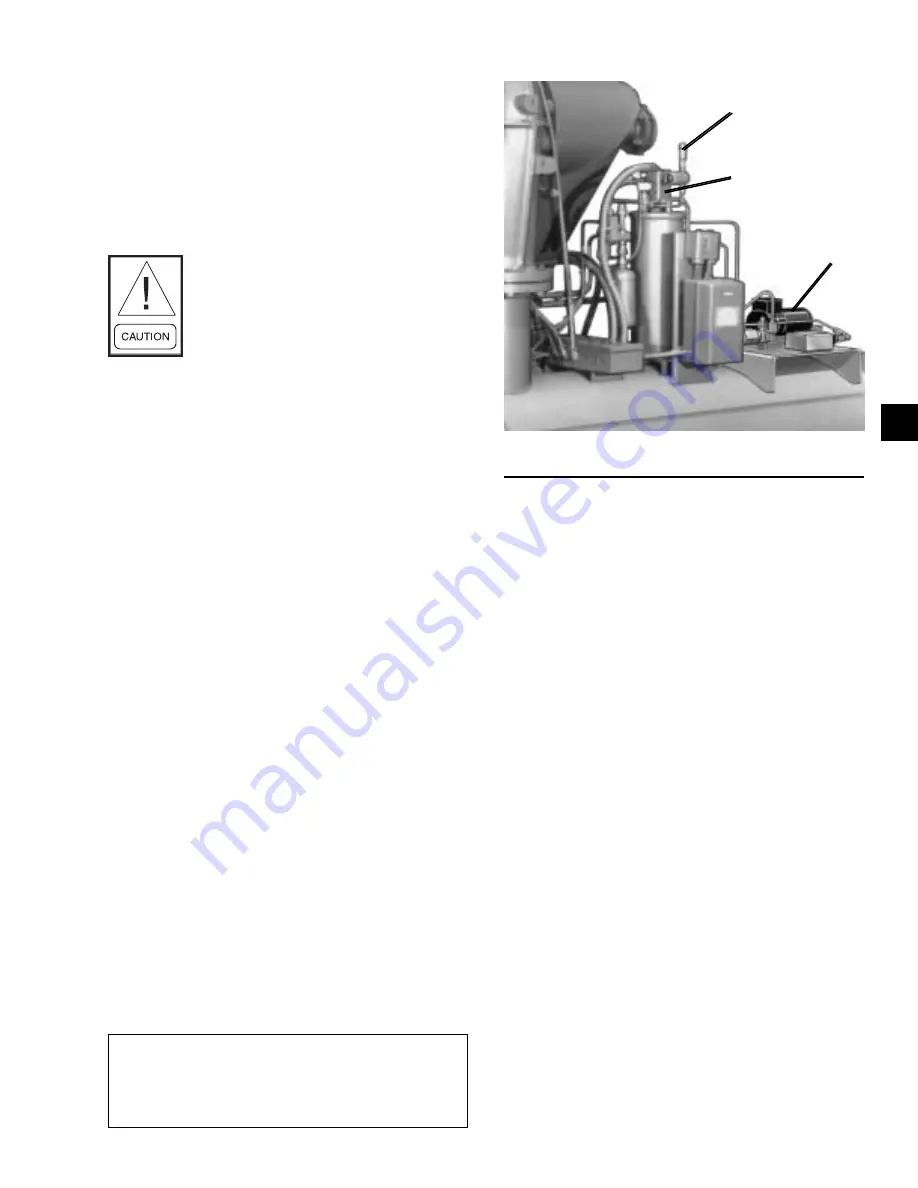

A Turboguard purge unit is fur nished and mounted at the

rear of the system (See Fig. 58). The purpose of this unit

is to au to mat i cal ly remove the mixture of nonconden-

sible gases and re frig er ant from the top of the con dens er,

expel the noncondensibles to the at mo sphere and return

the re frig er ant to the system.

IMPORTANT!

The purge unit operates con tin u ous ly

when the system is in operation.

FIG. 58

– TURBOGUARD PURGE UNIT

27046A(D)

CHECK VALVE

FLOAT SWITCH ASS’Y.

PUMP

The Turboguard purge unit in cludes a display mes-

sage on the control center dis play. The message reads

“WARN ING – EXCESS PURGE”

if an ex ces sive

air leak is present with in the chill er. The “

WARN ING

RE SET

” should be pushed with the OptiView Control

Cen ter in “

SER VICE

” mode to reset the display. Leak

check and cor rect the leak if the dis play continues to

show this mes sage.

NORMAL AND SAFE TY SYS TEM SHUTDOWNS

Normal and safety system shutdowns have been built

into the chiller to protect it from dam age during certain

op er at ing conditions. There fore, it should be un der stood

that at certain pres sures and tem per a tures the system will

be stopped au to mat i cal ly by controls that respond to high

tem per a tures, low tem per a tures, and low and high pres-

sures, etc. The “Display Messages” section is an ex pla -

na tion of each spe ci

Þ

c shut down. If the chiller shuts down

on a “Safe ty” shut down the cause is dis played.

STOPPING THE SYSTEM

The OptiView Control Cen ter can be pro grammed to start

and stop au to mat i cal ly (max i mum, once each day) when-

ev er desired. To stop the chill er pro ceed as fol lows:

1. Push the compressor switch to “

STOP/RESET

”. The

OptiView Control Center display will show “

SYS-

TEM COASTDOWN”

for 150 seconds (6 min. if

Microboard jumper JP36 removed). The com pres sor,

4