Reviews:

No comments

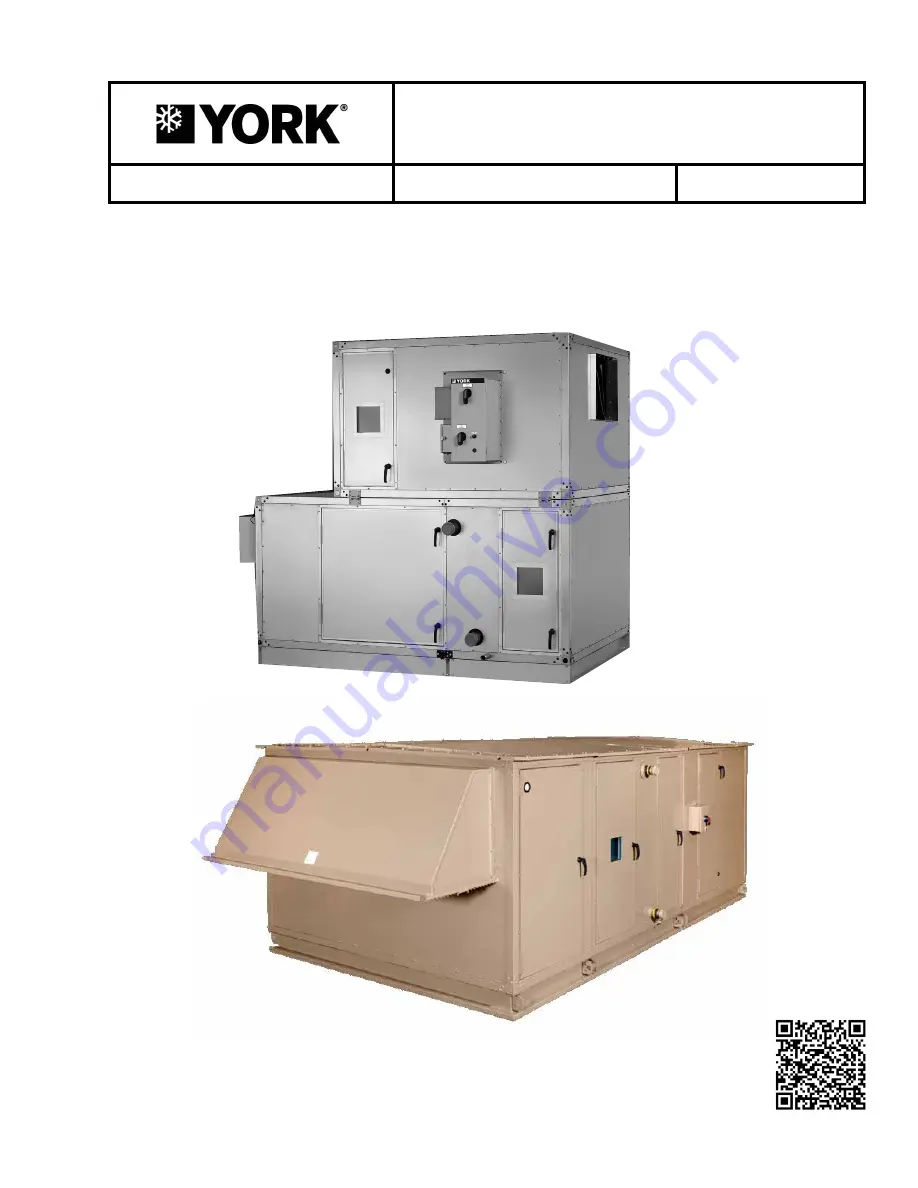

Related manuals for SOLUTION XTI Series

FWD 08

Brand: Trane Pages: 20

combo-pac

Brand: Vortex Pages: 23

Air Handler CB26UH

Brand: Lennox Pages: 15

VRF VEAH024C432P

Brand: Lennox Pages: 22

Topvex SC Series

Brand: SystemAir Pages: 54

RoofVent KG

Brand: Hoval Pages: 40

RoofVent R Series

Brand: Hoval Pages: 48

RoofVent CON-9

Brand: Hoval Pages: 280

GAF-365

Brand: Gourmia Pages: 9

GAF-355

Brand: Gourmia Pages: 9