JOHNSON CONTROLS

104

FORM 102.20-N1

ISSUE DATE: 7/06/2016

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

LD20623

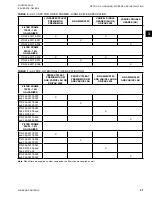

FIGURE 166 -

KOCH HF

Welded Bevel Seal Frame

Extruded Aluminum Frames

The bevel seal frame is a factory welded, extruded alu-

minum frame developed specifically for High Efficien-

cy Particulate Air (HEPA) filter installations. Standard

bevel seal frames accommodate multiple sizes of gas-

keted HEPA filters 11-1/2 in. deep as shown in

Two Stage Gasket Compression

The bevel seal frame features a two level sealing surface

connected by a bevel, which causes the filter gasket to

be compressed in two stages as clamping pressure is

applied. The outer edge of the gasket is compressed to

a greater degree than the inner portion of the gasket, as

Do not apply excess clamping pressure

because the individual cells in the gasket

material may fracture, causing the gasket

to relax, allowing leakage.

FIGURE 167 -

HEPA FILTER (CROSS SECTION)

LD06674a

2 in

2 in

2 in

T-Section

Perimeter Section

Type H

Main Runner

Perimeter Extrusion

VISUAL CONTROL FILTER CLAMPS

HEPA Filter Applications

Visual control clamps, as shown in

are designed to use with any conventional gas-

keted HEPA filter. Located at midpoint of each filter

edge, the calibrated spring-loaded clamps maintain up to

100 lb pressure against the filter at each clamping point.

Four clamps, which have a 1-1/2 in. wide bearing sur-

face, are used per filter to assure there is uniform pres-

sure against the gasket.

Installing the Easy Clamp

No special tools are required to install the clamp prop-

erly. Tighten the bolt head until it is flush with the

clamp face to achieve the prescribed compression.

Proper clamping pressure is created indefinitely by the

calibrated spring.

Single filter clamps are used around the perimeter of the

frame bank. Double clamps are used along main runners

to secure a filter on either side of the T-section as shown

in