JOHNSON CONTROLS

72

FORM 102.20-N1

ISSUE DATE: 7/06/2016

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

10. If the heater is wired to a heating/cooling thermo-

stat, use a thermostat with isolating circuits to pre-

vent possible interconnection of Class 2 outputs.

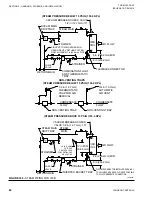

11. If the heating elements are divided into several

sections with resistance wire between two or more

sections, calculate the maximum kW per sq. ft as

follows:

Number of heated

sections x area of

one heated section

Heater nameplate KW

ELECTRIC HUMIDIFIER

It's the installer's responsibility to wire this device be-

cause this device is not included in the single point

power option.

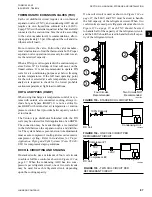

represents a typical electric

humidifier panel layout. The supply power knockout is

located in the bottom of the electrical panel as shown

in

. All conduits beginning or

ending on the inside of the pressurized or conditioned

areas (i.e. AHU) must have the conduit openings sealed

to prevent air from passing through it.

FIGURE 110 -

LAYOUT OF TYPICAL HUMIDIFIER

PANEL

LD11726

FIGURE 111 -

SUPPLY POWER KNOCKOUTS

LD11727

KNOCKOUTS

All AHU penetrations must be sealed to prevent air and

water leakage. Refer to

and Electrical Connections on page 63

.

Field provided disconnects must provide circuit pro-

tection according to the humidifier nameplate. All field

wiring to the humidifier must be in accordance with

NEC and local codes.

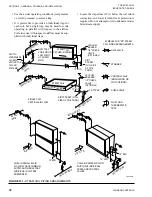

HUMIDIFIER

Control wiring diagrams are located in the humidi-

fier manufacturer's operator's manual, which can be

found inside the control panel or it is attached. Factory

package control drawings may not include humidifier

points as shown in

FIGURE 112 -

HUMIDIFIER POINTS

LD11725

If the humidifier operator's manual cannot be located

inside the humidifier, call Johnson Controls Airside

Product Technical Support to get a copy of the elec-

tronic version.