JOHNSON CONTROLS

75

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

FORM 102.20-N1

ISSUE DATE: 7/06/2016

3

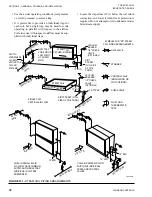

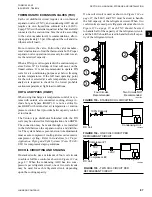

Hot and Chilled Water Coils

1. Connect the water supply to the header connec-

tion on the leaving air side of the coil to achieve

the counter flow of water and air. The return pipe

will be connected to the remaining coil connec-

tion.

2. Install an air vent in place of the top pipe plug on

the return header. To provide for drainage, install

a drain line and shutoff valve in the supply near

the coil, or in place of the plug in the supply con-

nection as shown in

Water Coil Performance

Full steam pressure of water flow must be

supplied at all times - modulating valves

must not be used. A modulating steam

valve or preheat coil can actually cause

the coil to retain condensate due to a re-

duced pressure in the coil thus exposing

condensate in the tubes to freezing condi-

tions. With modulating steam below 5 psig

(valve closure) the steam may not be fully

distributed in all of the tubes in the coil,

causing the outer tube to cool abnormally.

This will create thermal stress that can

lead to possible "outer tube failure".

The temperature rise of the air (hot water coil) or tem-

perature fall of the air (chilled water coil) leaving the

coil is dependent on the:

• Airflow across the coil,

• Gallons of water flow through the coil, and

•

Entering water temperature into the coil.

Consult the job submittal form for more information.

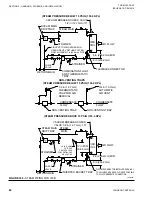

FIGURE 118 -

CHILLED WATER COIL CONNECTIONS EXAMPLE - (NOT FOR CONSTRUCTION)

LD12470

VENT

RETURN

RETURN

SUPPLY

SUPPLY

COIL

COIL

PT

PLUG

DRAIN

UNION

GLOBE

VALVE

GATE

VALVE

PT

PLUG

GATE VALVE W/

HOSE BIB

UNION

GLOBE

VALVE

REDUCING

TEE

CHILLED

WATER

SUPPLY

CHILLED

WATER

RETURN

3 WAY CONTROL VALVE

ECCENTRIC

REDUCER

STRAINER