JOHNSON CONTROLS

83

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

FORM 102.20-N1

ISSUE DATE: 7/06/2016

3

REFRIGERATION

DX Direct Expansion Coils

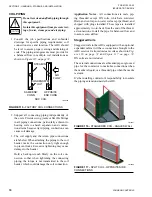

DX coils are often divided into splits, depending upon

the AHU size and coil circuiting. Each split requires

its own distributor nozzle, expansion valve and suc-

tion piping. Suction headers are on the air entering side

with suction connection at the bottom end of the head-

ers when the coil is properly installed. Matching dis-

tributor connections for each coil refrigeration circuit

are on the air leaving side. Refer to the drawing and/or

connection labeling to ensure the suction and distribu-

tor connections are matched correctly.

Direct expansion coils are shipped

charged with nitrogen.

Do not leave the piping open to the atmosphere unnec-

essarily. Water and water vapor are detrimental to the

refrigerant system. Until the piping is complete, recap

the system and charge with nitrogen at the end of each

day. Clean all piping connections before brazing the

joints.

The orientation of the refrigerant distributor is not criti-

cal, but the distributor tubes must not be kinked or bent

in a non-uniform configuration. For other piping and

DX Coil Types

Three types of coil arrangements are used in field

mounted split systems: interlaced, row split and face

split.

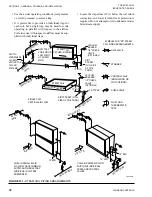

Interlaced

- These coils are the most desirable type of

coil field mounted designs. Interlaced coils ensure the

entire face of the coil is active with any number of op-

erating compressors. Interlaced circuitry interweaves

the coil tubing in both circuits across the entire face

of the coil, assuring uniform cooling of the air by the

refrigerant. This type of coil also allows one circuit to

operate while the other circuit is turned off. Interlaced

coils provide excellent temperature control at full and

part loads as well as good thermal expansion valve

(TXV) superheat control, which is essential for com-

pressor reliability.

Row Split

- Row split coils arrangements place coils

back-to-back in the air stream. Air passes through one

coil before passing through the next coil. Generally, the

last coil in the air stream is activated first. Each circuit

may be controlled independently in this arrangement.

When both coils are operating, the coil closest to the

leaving air will operate at a lower temperature. This

type of coil may not permit lead lag of the circuits and

it may be difficult to balance the capacity between the

coils.

Face Split

- On this coil, the circuiting is divided be-

tween two separate coils. In field mounted systems,

this arrangement may suffer from TXV superheat con-

trol problems and compressor reliability. At low air-

flow, low load situations, the TXV may have difficulty

controlling the system's superheat.

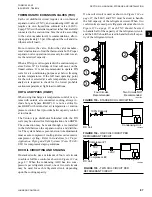

Air stratification, poor humidity control, and con-

densation on downstream components can also occur

when using face split coils. One way to address TXV

control at part load is to provide a face damper to shut

off airflow when a coil face is inactive.

Combined Coil Types

Coil types may be combined in some systems, which

requires special care. Control sequences and piping ty-

ing the multiple systems and coils together should be

well thought out. Advice from an experienced design

engineer may be necessary.

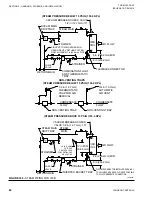

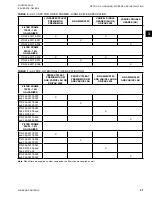

DX Coil Circuiting

On many coil banks, two, or all three circuiting meth-

ods may be combined, depending upon the cooling ca-

pacity, and the level of control required. However, coil

sections must be combined so that they provide full-

face operation as shown in

Refer to

for the available

standard and special quote arrangements from the

Johnson Controls coil marketing group.