JOHNSON CONTROLS

26

FORM 102.20-N1

ISSUE DATE: 7/06/2016

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

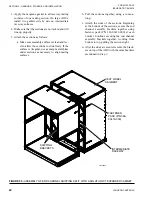

FIGURE 15 -

MINIMUM SERVICE CLEARANCES

LD6326-4

MIN. CLEARANCE DIMENSIONS

A

B

C

D

E

F

G

H

Fan Section

Coil Section

Face and Bypass Damper Section

Filter Section - Door should open 180°

Inlet Section

Rain Hood (add unit width or length)

Pipe Chase Enclosure (add to unit width)

Coil Access Panel on Outdoor Unit

(allow clearance = to unit width)

A

B C D

E

F

G

H

24"

24"

24"

UNIT WIDTH + 6 IN.

Assembling the Johnson Controls Provided

Curb

The curb, which supports the AHU, will be shipped

unassembled, and requires assembly on the job site.

Assembly drawings and a hardware package, which

includes a nailer and gasket

,

are shipped with each

curb. All other parts such as wood or fiber cant strips,

roofing felts and material, caulking, and curb-to-roof

fasteners are field supplied.

If there are questions about the number of curb parts or

assembling the curb, notify a Johnson Controls Field

Service Office immediately.

Use the following instructions to assemble the curb:

1. Unpack the shipping package. Layout the parts

according to the exploded views.

2. Layout all channel pieces as shown in

Make certain that all channel tabs

are located on inside of the mating channel. and

that all curb walls, accessories, and flanges, which

may have been distorted in handling, are straight-

ened before assembly.

3. Attach the curb walls together to form rectangular

perimeter as shown, leaving bolts loose. After the

curb is set in place, ensure proper consideration

has been given to the air duct openings through

the roof.

4. The curb installation drawing shows a gasket that

is mounted between the curb and the unit as shown

in

. This gasket is shipped

with the curb parts. Install the curb gasket before

setting the AHU on the curb. The gasket forms an

air seal between the AHU and the curb and serves

as a dampener, preventing metal-to-metal contact

between the AHU and curb. However, the gasket

should not be used as a vibration isolator where

the prevention of noise and vibration transmission

into the building is critical.

When the AHU is shipped in skids,

replace the curb gasket with the caulk

provided by contractor.

5. After verifying the curb is square and level, tight-

en all bolts, and then anchor appropriately. DO

NOT tighten the bolts after anchoring because the

curb will be pulled, twisted, and torqued out of

square.

6. Mark the exact location for the pipe chase curb.

Drill and assemble the pipe chase curb. The job

submittal drawing package contains a curb draw-

ing that shows the dimensions of the curb and pipe

chase.

7. Insulate and roof the curb as required. Refer to

Sheet Metal and Air Conditioning Contractors

National Association (SMACNA)

for counter

flash information.

Steel Frame

When a steel frame is used to support the AHU, it must

be level, flat without uneven steel frame joints, and

support the AHU around the full perimeter. As a gen-

eral rule, cross members should be placed every 96 in.,

in addition to each shipping split.