JOHNSON CONTROLS

45

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

FORM 102.20-N1

ISSUE DATE: 7/06/2016

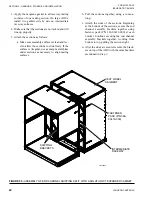

Carefully place each section of the top tier without dis-

turbing the gaskets on the bottom tier.

13. Secure the top tier to bottom tier with 3/8 in. x

0.75 in. allen head bolts.

14. Install the corner connector hole plugs (P/N 021-

19568-000) as shown in

onto the bottom raceway corners.

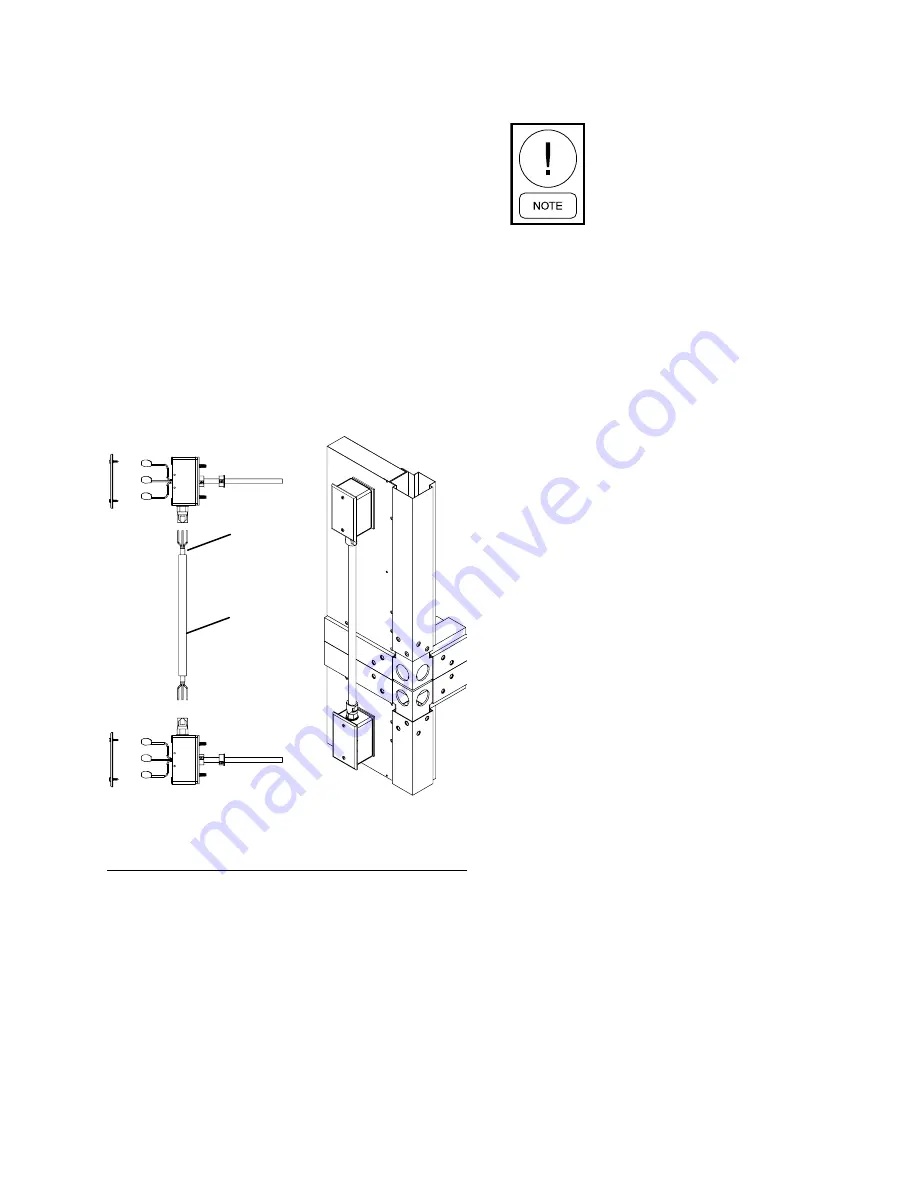

Lights for Tiered Solution XT AHU (If Appli-

cable)

If the AHU is equipped with lights, the following parts

are shipped loose on a tiered unit, as shown in

•

Conduit (P/N 025-39024-001)

•

SJO Cord (P/N 025-35746-01)

JUMPER

FIGURE 69 -

SOLUTION XT LIGHTS TIER

TRANSITION DRAWING

LD16602

CONDUIT

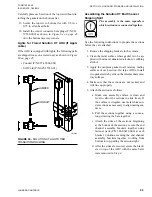

Assembling the Solution XT End Channel

Shipping Split

The assembly is the same regardless

which sections are connected together.

Use the following instructions to prepare the sections

before they are attached.

1. Remove the shipping brackets in the corners.

2. Clean the metal surface where gasket is to be ap-

plied with mineral denatured alcohol or rubbing

alcohol.

3. Apply the neoprene gasket to all raceway mating

surfaces of each section. On large AHUs, install

two gaskets side by side on the intermediate race-

way surfaces.

4. Make sure that the sections are not racked, and

will line up properly.

5. Attach the sections as follows:

a. Make sure assembly surface is clean and

level to allow the sections to slide freely. If

the surface is irregular, use metal shims un-

der sections as necessary to align mating sur-

faces.

b. Pull the sections together using a come-a-

long, drawing the base together.

c. Attach the sides of the sections. Beginning

at the bottom of the sections, secure the end

channel assembly brackets together using

fastener pack (P/N 386-03419-000) at each

bracket. Continue securing the end channel

assembly brackets together, working from

bottom to top, pulling the sections tight.

d. After the sides are secured, secure the brack-

ets on top of the AHU with the same hard-

ware removed in

Step

4

.