Johnson Controls Ducted Systems

5532522-UIM-B-0619

SINGLE STAGE ECM

RESIDENTIAL GAS FURNACES

MODELS: TL8E

(80% Upflow/Horizontal - Ultra Low NOx

Natural Gas Only)

INSTALLATION MANUAL

LIST OF SECTIONS

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

GAS PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ELECTRICAL POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

VENT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

START-UP AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . 13

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

OPERATION & DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . . 19

REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . 21

REPLACEMENT PART CONTACT INFORMATION . . . . . . . . 21

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

START UP SHEET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

LIST OF FIGURES

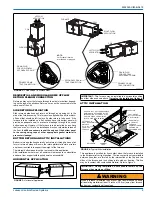

Duct Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Furnace and Coil Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

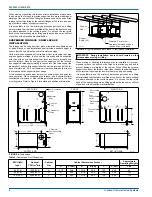

Horizontal Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Typical Attic Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Typical Suspended Furnace / Crawl Space Installation . . . . . . . . . . . 6

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Side Return Cutout Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

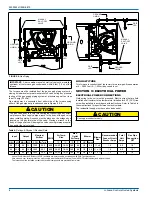

Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Thermostat Chart - Single Stage AC with Single Stage Furnaces . . . 9

Thermostat Chart - Single Stage HP with Single Stage Furnaces . .10

Thermostat Chart - 1H/2C - Single Stage

Furnace (STD-ECM) - Two Stage Air Conditioner . . . . . . . . . . . . . .10

Combustion Air Inducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Combustion Airflow Path Through The Furnace

Casing to the Burner Compartment . . . . . . . . . . . . . . . . . . . . . . . . . 11

Outside and Ambient Combustion Air . . . . . . . . . . . . . . . . . . . . . . . . 12

Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Reading Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Furnace Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

LIST OF TABLES

Unit Clearances to Combustibles (All Dimensions in Inches, and All

Surfaces Identified with the Unit in an Upflow Configuration) . . . 3

Cabinet and Duct Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Recommended Filter Sizes (High Velocity 600 FPM) . . . . . . . . . 7

Ratings & Physical / Electrical Data . . . . . . . . . . . . . . . . . . . . . . 8

Estimated Free Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Unconfined Space Minimum Area . . . . . . . . . . . . . . . . . . . . . . . 12

Free Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Gas Rate (CU FT/HR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Inlet Gas Pressure Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

New: Nominal Manifold Pressure . . . . . . . . . . . . . . . . . . . . . . . 16

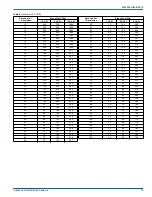

Blower Performance CFM - Any Position (without filter) . . . . . . 18

These high efficiency, compact units employ induced combustion, reli-

able hot surface ignition and high heat transfer tubular heat exchang-

ers. The units are factory shipped for installation in upflow or horizontal

applications.

These furnaces are designed for residential installation in a basement,

closet, alcove, attic, recreation room or garage and are also ideal for

commercial applications. All units are factory assembled, wired and

tested to assure safe dependable and economical installation and oper-

ation.

These units are Category I listed and may be common vented with

another gas appliance as allowed by the National Fuel Gas Code.

SECTION I: SAFETY

This is a safety alert symbol. When you see this symbol on

labels or in manuals, be alert to the potential for personal

injury.

Understand and pay particular attention to the signal words

DANGER

,

WARNING

, or

CAUTION

.

DANGER

indicates an

imminently

hazardous situation, which, if not

avoided,

will result in death or serious injury

.

WARNING

indicates a

potentially

hazardous situation, which, if not

avoided,

could result in death or serious injury

.

CAUTION

indicates a potentially hazardous situation, which, if not

avoided

may result in minor or moderate injury.

It is also used to

alert against unsafe practices and hazards involving only property dam-

age.

SPECIFIC SAFETY RULES AND PRECAUTIONS

1. Only Natural gas is approved for use with this furnace.

2. Install this furnace only in a location and position as specified in

these instructions.

3. A gas-fired furnace for installation in a residential garage must be

installed as specified in these instructions.

4. Provide adequate combustion and ventilation air to the furnace

space as specified in these instructions.

5. Combustion products must be discharged outdoors. Connect this

furnace to an approved vent system only, as specified in SECTION

VI of these instructions.

6. Test for gas leaks as specified in these instructions.

WARNING

Improper installation may create a condition where the operation of

the product could cause personal injury or property damage.

Improper installation, adjustment, alteration, service or maintenance

can cause injury or property damage.

Failure to carefully read and

follow all instructions in this manual can result in furnace mal-

function, death, personal injury and/or property damage.

Only a

qualified contractor, installer or service agency should install this

product.

!