5532522-UIM-B-0619

8

Johnson Controls Ducted Systems

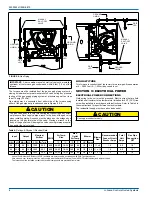

The furnace must be isolated from the gas supply piping system by

closing its individual external manual shutoff valve during any pressure

testing of the gas supply piping system at pressures equal to or less

than 1/2 psig (3.5 kPa).

Gas piping may be connected from either side of the furnace using

either of the gas pipe entry locations shown in Figures 6 & 9.

HIGH ALTITUDE

This furnace is constructed at the factory for natural gas-fired operation

at 0 – 5,000 feet (0 – 1,524 m) above sea level.

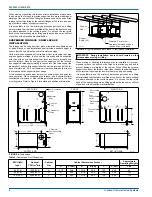

SECTION V: ELECTRICAL POWER

ELECTRICAL POWER CONNECTIONS

Field wiring to the unit must be grounded. Electric wires that are field

installed shall conform to the temperature limitation for 63ºF (35ºC) rise

wire when installed in accordance with instructions. Refer to Table 4 in

these instructions for specific furnace electrical data.

The residential supply must have a bonded neutral.

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

The furnace shall be installed so that the electrical components are protected from water.

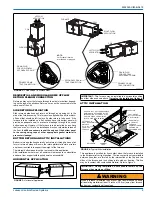

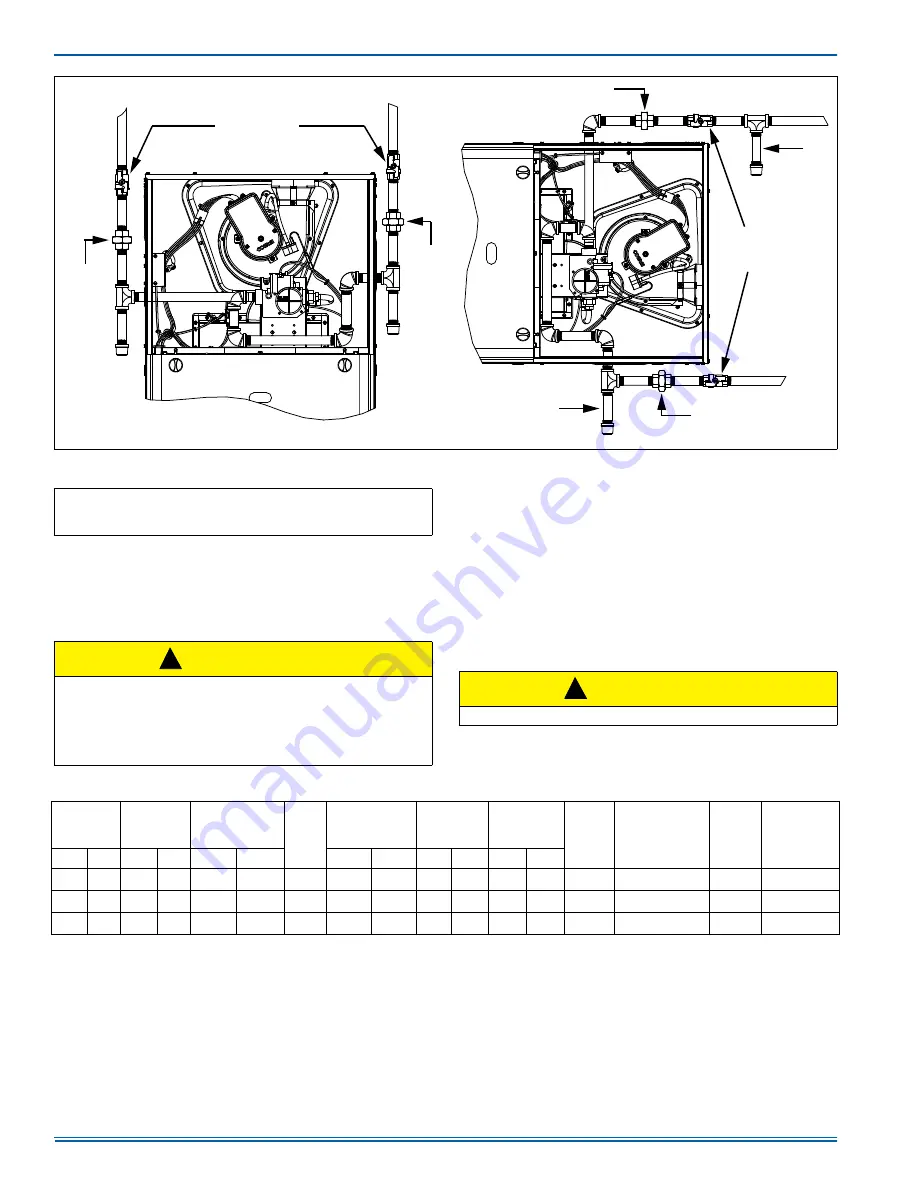

FIGURE 9:

Gas Piping

GROUND

UNION

DRIP

LEG

MANUAL

SHUT-OFF

VALVE

GROUND

UNION

DRIP

LEG

UPFLOW

DRIP

LEG

DRIP

LEG

GROUND

UNION

MANUAL

SHUT-OFF

VALVE

GROUND

UNION

IMPORTANT:

An accessible manual shutoff valve must be installed

upstream of the furnace gas controls and within 6 feet (1.8 m) of the

furnace.

CAUTION

The gas valve body is a very thin casting that cannot take any exter-

nal pressure. Never apply a pipe wrench to the body of the gas valve

when installing piping. A wrench must be placed on the octagon hub

located on the gas inlet side of the valve. Placing a wrench to the

body of the gas valve will damage the valve causing improper opera-

tion and/or the valve to leak.

!

CAUTION

Use copper conductors only.

!

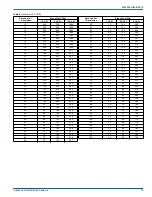

Table 4:

Ratings & Physical / Electrical Data

Input

Output

Nominal

Airflow

AFUE

Air Temp.

Rise

Max.

Outlet

Air Temp

Blower

Blower

Size

Recommended

Fuse or Circuit

Breaker Amps

Total

Unit

Amps

Gas Pipe

Connection,

NPT

MBH

kW MBH kW

CFM

m

3

/min

ºF

ºC

ºF

ºC

HP

Amps

60

17.6

48

14.1

1200

34.0

80.0

35-65

19-36

190

88

1/2

6.4

11 x 8

15

9.0

1/2"

80

23.5

64

18.8

1600

45.3

80.0

35-65

19-36

190

88

1/2

6.4

11 x 10

15

9.0

1/2"

100 29.3

80

23.4

2000

56.6

80.0

35-65

19-36

190

88

3/4

8.8

11 x 11

15

11.4

1/2"