5532522-UIM-B-0619

6

Johnson Controls Ducted Systems

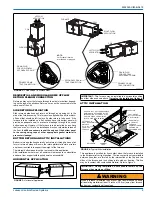

When moving or handling this furnace prior to installation, always leave

the doors on the furnace to provide support and to prevent damage or

warping of the cabinet. When lifting the furnace, support the ends of the

furnace rather than lifting by the cabinet flanges at the return air open-

ings (bottom or sides) or supply air opening.

It is acceptable to use the primary heat exchanger tubes as a lifting

point provided that the tubes are lifted at the front of the heat exchang-

ers where attached to the vestibule panel. Do not use the top return

bend of the heat exchangers as lifting points as the tubes may shift out

of position or their location brackets/baffles.

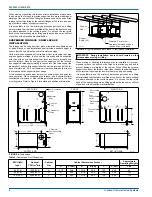

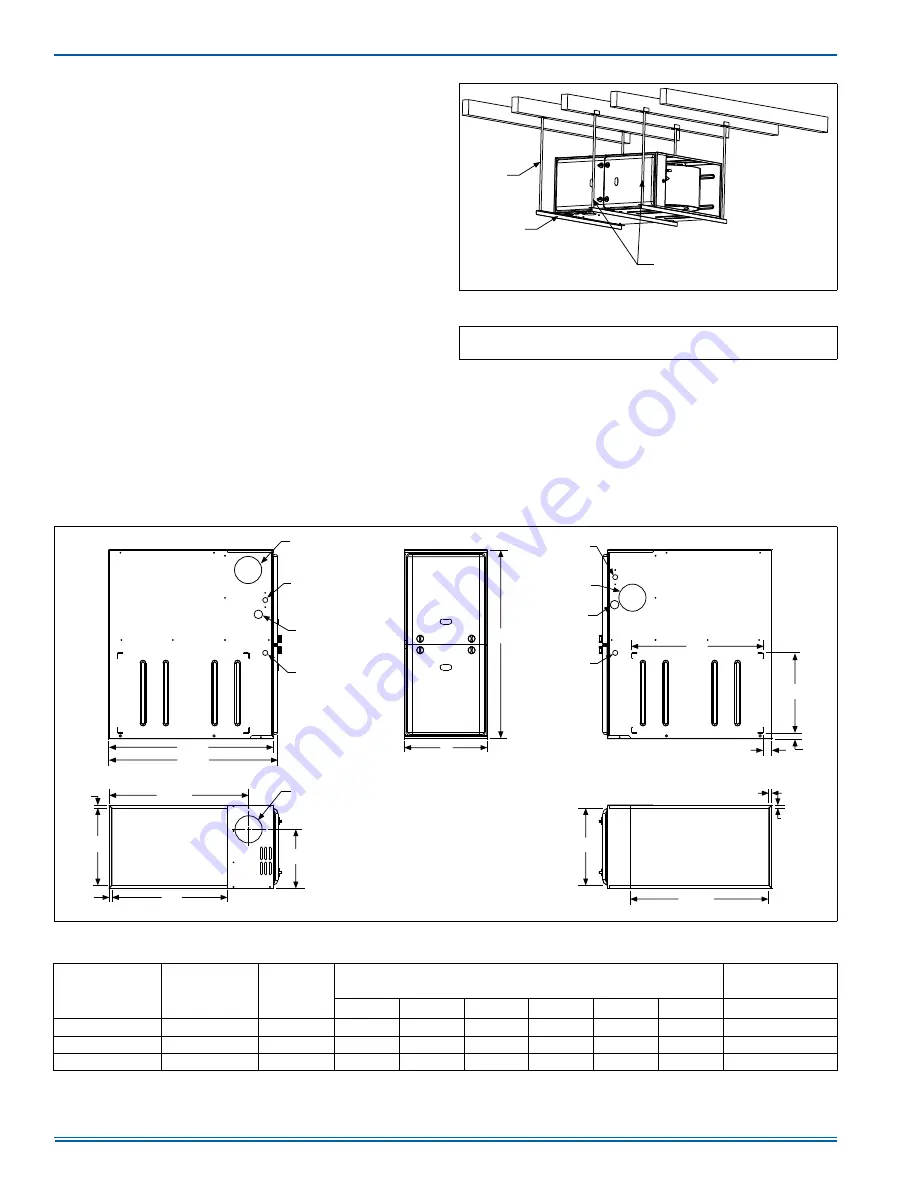

SUSPENDED FURNACE / CRAWL SPACE

INSTALLATION

The furnace can be hung from floor joists or installed on suitable blocks

or pads. Blocks or pad installations shall provide adequate height to

ensure that the unit will not be subject to water damage.

Units may also be suspended from rafters or floor joists using rods, pipe

angle supports or straps. In all cases, the furnace should be supported

with rods, straps, or angle supports at three locations to properly sup-

port the furnace. Place one support at the supply end of the furnace,

one support located approximately in the center of the furnace near the

blower shelf, and the third support should be at the return end of the fur-

nace. Maintain a 6” (15.2 cm) minimum clearance between the front of

the furnace and the support rods or straps.

All six suspension points must be level to ensure proper and quiet fur-

nace operation. When suspending the furnace, use a secure platform

constructed of plywood or other building materials secured to the floor

or ceiling joists. Refer to Figure 5 for details and additional information.

When moving or handling this furnace prior to installation it is recom-

mended to leave the doors on the furnace to provide support and to

prevent damage or warping of the cabinet. When lifting the furnace,

support the ends of the furnace rather than lifting by the cabinet flanges

at the return air openings (bottom or sides) or supply air opening.

It is acceptable to use the primary heat exchanger tubes as a lifting

point provided that the tubes are lifted at the front of the heat exchang-

ers where attached to the vestibule panel. Do not use the top return

bend of the heat exchangers as lifting points as the tubes may shift out

of position or their location brackets/baffles.

FIGURE 5:

Typical Suspended Furnace / Crawl Space Installation

IMPORTANT: During installation, doors should remain on the

furnace when moving or lifting.

6XSSRUW

5RG

6XSSRUW

$QJOH[

0DLQWDLQ´PLQLPXP

FOHDUDQFHEHWZHHQVXSSRUW

URGVDQGIURQWRIIXUQDFH

$

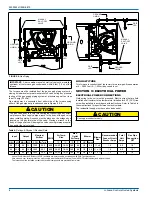

FIGURE 6:

Dimensions

Table 2:

Cabinet and Duct Dimensions

BTUH (kW)

Input

Nominal

CFM (m

3

/min)

Cabinet

Size

Cabinet Dimensions (Inches)

Approximate

Operating Weights

A

A (cm)

B

B (cm)

C

C (cm)

Lbs

60 (17.6)

1200 (34.0)

A

14 1/2

36.8

13 3/8

34.0

10.3

26.2

94

80 (23.4)

1600 (45.3)

C

21

53.3

19 7/8

50.5

13.6

34.5

114

100 (29.3)

2000 (56.6)

C

21

53.3

19 7/8

50.5

13.6

34.5

122

/()76,'(

5,*+76,'(

´

´

5(7851(1'

%

´

´

´

(OHFWULFDO

(QWU\

*DV3LSH

(QWU\

7KHUPRVWDW

:LULQJ

)5217

´

´

´

´

6833/<(1'

&

´

´

´

%

*DV3LSH

(QWU\

7KHUPRVWDW

:LULQJ

´

$

´

(OHFWULFDO

(QWU\

9HQW&RQQHFWLRQ

2XWOHW

9HQW

&RQQHFWLRQ

2XWOHW

´'LDPHWHU

9HQW&RQQHFWLRQ

2XWOHW

$