5894307-UIM-B-0920

4

Johnson Controls Ducted Systems

*24 in. clearance in front and 18 in. on side recommended for service access.

Note:

All furnaces are approved for alcove and attic installation.

SECTION II: DUCTWORK

DUCTWORK GENERAL INFORMATION

The duct system’s design and installation must:

• Handle an air volume appropriate for the served space and within

the operating parameters of the furnace specifications.

• Be installed in accordance with National Fire Protection Associa-

tion as outlined in NFPA standard 90B (latest editions) or applica-

ble national, provincial, state, and local fire and safety codes.

• Create a closed duct system. When a furnace is installed so the

supply ducts carry air circulated by the furnace to areas outside

the space containing the furnace, the return air must also be han-

dled by a duct or ducts sealed to the furnace casing and terminat-

ing outside the space containing the furnace.

• Complete a path for heated or cooled air to circulate through the

air conditioning and heating equipment and to and from the con-

ditioned space.

When the furnace is used with an indoor coil, the coil must be installed

parallel with, or in the supply air side of the furnace to avoid condensa-

tion in the primary heat exchanger. When a parallel flow arrangement is

used, dampers or other means used to control airflow must be ade-

quate to prevent chilled air from entering the furnace. If manually oper-

ated, the damper must be equipped with means to prevent the furnace

or the air conditioner from operating unless the damper is in full heat or

cool position.

When replacing an existing furnace, if the existing plenum is not the

same size as the new furnace, the existing plenum must be removed

and a new plenum installed that is the correct size for the new furnace.

If the plenum is shorter than 12 in. (30.5 cm) the turbulent airflow may

cause the limit controls not to operate as designed, or the limit controls

may not operate at all.

The duct system is a very important part of the installation.

If the duct

system is incorrectly sized, the furnace does not operate correctly.

The ducts attached to the furnace plenum must be of sufficient size so

the furnace operates at the specified external static pressure and within

the air temperature rise specified on the nameplate.

If a matching cased indoor coil is used, it can be placed directly on the

furnace outlet and sealed to prevent leakage. If an uncased indoor coil

with a thermoplastic drain pan is installed in the upflow/horizontal con-

figuration, an extra 2 in. minimum spacing may be needed to ensure

against drain pan distortion.

On all installations without a coil, a removable access panel is recom-

mended in the outlet duct such that smoke or reflected light would be

observable inside the casing to indicate the presence of leaks in the

heat exchanger. This access cover must be attached in such a manner

as to prevent leaks.

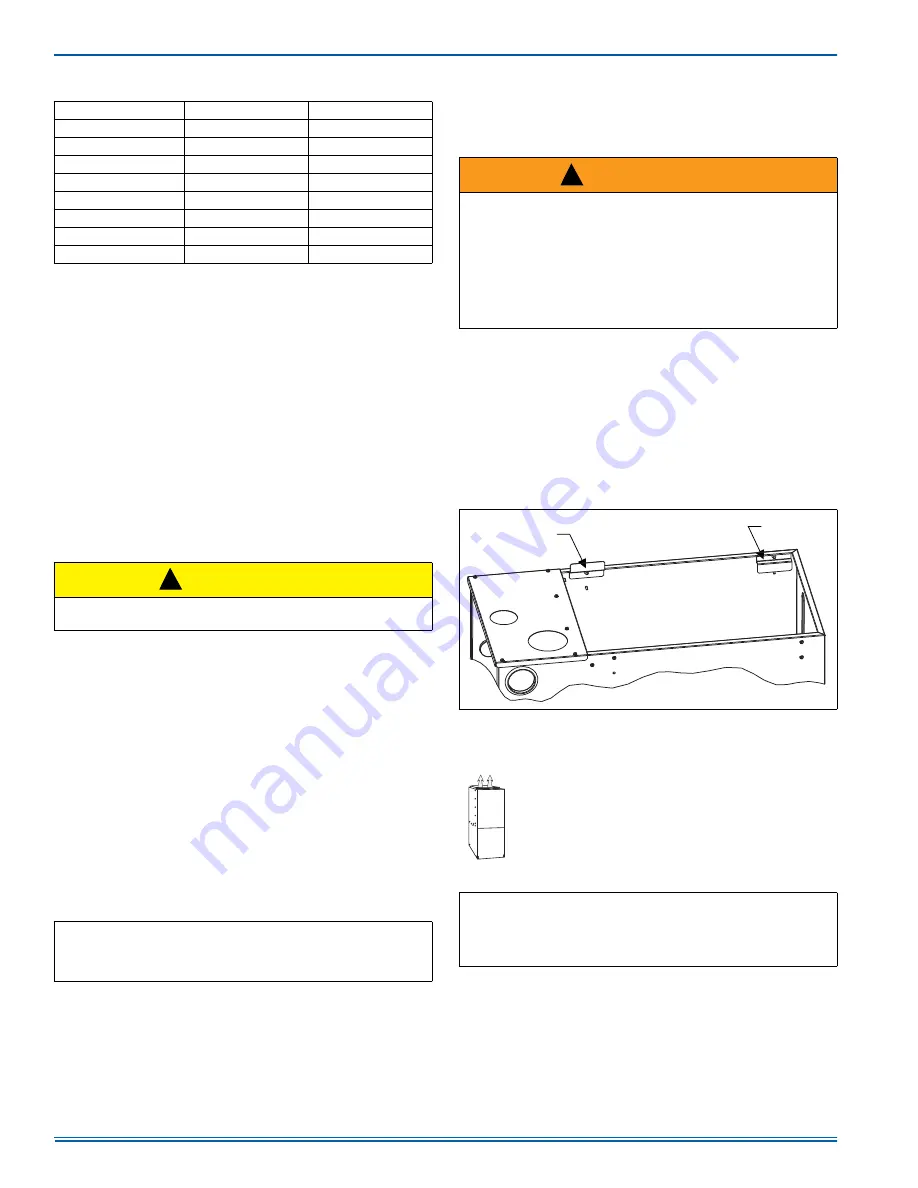

DUCT FLANGES

Four flanges are provided to attach ductwork to the furnace. These

flanges are rotated down for shipment. To use the flanges, do the fol-

lowing:

1. Remove the screw holding an individual flange.

2. Rotate the flange so it is in the upward position.

3. Reinstall the screw.

4. Repeat Steps 1 to 3 for all four flanges.

If the flanges are not used, they must remain in the rotated down posi-

tion as shipped.

DUCTWORK INSTALLATION AND SUPPLY PLENUM

CONNECTION

Attach the supply plenum to the furnace outlet. Use an

approved flexible duct connector for all installations. Seal

this connection to prevent air leakage. The sheet metal

must be crosshatched to eliminate any popping of the sheet

metal when the indoor fan is energized.

INDOOR COIL INSTALLATION

The indoor coil must be mounted on the supply side of the furnace as

shown in Figure 2. Refer to the installation instructions provided with

each indoor coil.

Table 1:

Unit Clearances to Combustibles

Application

Upflow

Horizontal

Top

1 in.

0 in.

Vent

0 in.

0 in.

Rear

0 in.

0 in.

Side

0 in.

1 in.

Front*

0 in.

0 in.

Floor

Combustible

Combustible

Closet

Yes

Yes

Line Contact

No

Yes

CAUTION

The indoor coil must be installed in the supply air duct, downstream of

the furnace. Cooled air may not be passed over the heat exchanger.

IMPORTANT:

The minimum plenum height is 12 in. (30.5 cm). The

furnace does not operate correctly on a shorter plenum height. The

minimum recommended rectangular duct height is 4 in. (10.1 cm)

attached to the plenum.

!

WARNING

The duct system must be properly sized to obtain the correct airflow

for the furnace size that is being installed.

Refer to the furnace rating plate for the correct rise range and static

pressures or to Table 4 for the correct rise range.

If the ducts are undersized, the result will be high duct static pres-

sures and/or high temperature rises which can result in a heat

exchanger OVERHEATING CONDITION. This condition can result in

premature heat exchanger failure, which can result in personal injury,

property damage, or death.

Figure 1:

Duct Attachment

IMPORTANT:

On all installations without an indoor coil, a removable

access panel is recommended in the outlet duct such that smoke or

reflected light would be observable inside the casing to indicate the

presence of leaks in the heat exchanger. This access cover must be

attached in such a manner as to prevent leaks.

!

Factory

installed

For duct attachment,

if needed.