5894307-UIM-B-0920

20

Johnson Controls Ducted Systems

DOWNWARD VENTING

In some applications, it may be necessary to run the vent pipe and air

intake downwards. If this is to be done, adhere to the following rules:

• A condensate trap hose must be connected to both the air intake

pipe and the vent pipe at the lowest part of the horizontal run.

• The condensate drain trap must have a trap of a minimum of 6 in.

• The total vertical downward distance must not exceed 16 ft.

• The condensate drain hose must be connected to a condensate

drain pump, to an open or vented drain, or into the condensate

drain line from the furnace.

• The condensate drain lines must not pass through unconditioned

spaces where the temperature may fall below freezing.

• The condensate drain lines must be primed at the initial start-up

before the start of heating season.

COMBUSTION AIR SUPPLY

All installations must comply with Section 5.3, Air for Combustion and

Ventilation of the National Fuel Gas Code, ANSI Z223.1 or Sections

7.2, 7.3, or 7.4 of CAN/CGA B149.1 or B149.2 Installation Code - latest

editions.

Install this furnace using one of the following combustion air intake con-

figurations.

•

OUTDOOR COMBUSTION AIR:

This is a direct vent configura-

tion where the combustion air is supplied through a PVC or ABS

pipe that is connected to the PVC coupling attached to the fur-

nace and is terminated in the same atmospheric zone as the

vent. This type of installation is approved on all models. See Fig-

ures 21 and 22.

•

AMBIENT COMBUSTION AIR:

Combustion air is supplied from

the area surrounding the furnace through openings in the furnace

casing. The combustion air and the vent pipes are not terminated

in the same atmospheric zone. See Figure 20 for vent termina-

tions. See the Ambient Combustion Air Supply section for proper

installation. See Figure 28.

•

VENTILATED COMBUSTION AIR:

Combustion air is supplied

through a PVC or ABS pipe that is connected to the PVC coupling

attached to the burner box and is terminated in a ventilated attic

or crawl space. The combustion air and the vent pipes are not ter-

minated in the same atmospheric zone. See Figure 29 for attic

and crawl space termination. Only the combustion air intake can

terminate in the attic. The vent must terminate outside.

Outdoor Combustion Air

Combustion Air Intake/Vent Connections

This installation requires combustion air to be brought in from outdoors.

This requires a correctly sized pipe (shown in Figure 25) that brings air

in from the outdoors to the furnace combustion air intake collar on the

burner box. The second pipe (shown in Figure 25) is the furnace vent

pipe.

The combustion air intake pipe must be located either through the wall

(horizontal or side vent) or through the roof (vertical vent). Care must be

taken to locate side vented systems where trees or shrubs do not block

or restrict supply air from entering the terminal.

The terminal assembly must be located as far as possible from a swim-

ming pool or a location where swimming pool chemicals might be

stored. Make sure the terminal assembly follows the outdoor clear-

ances listed in the VENT APPLICATIONS AND TERMINATION section.

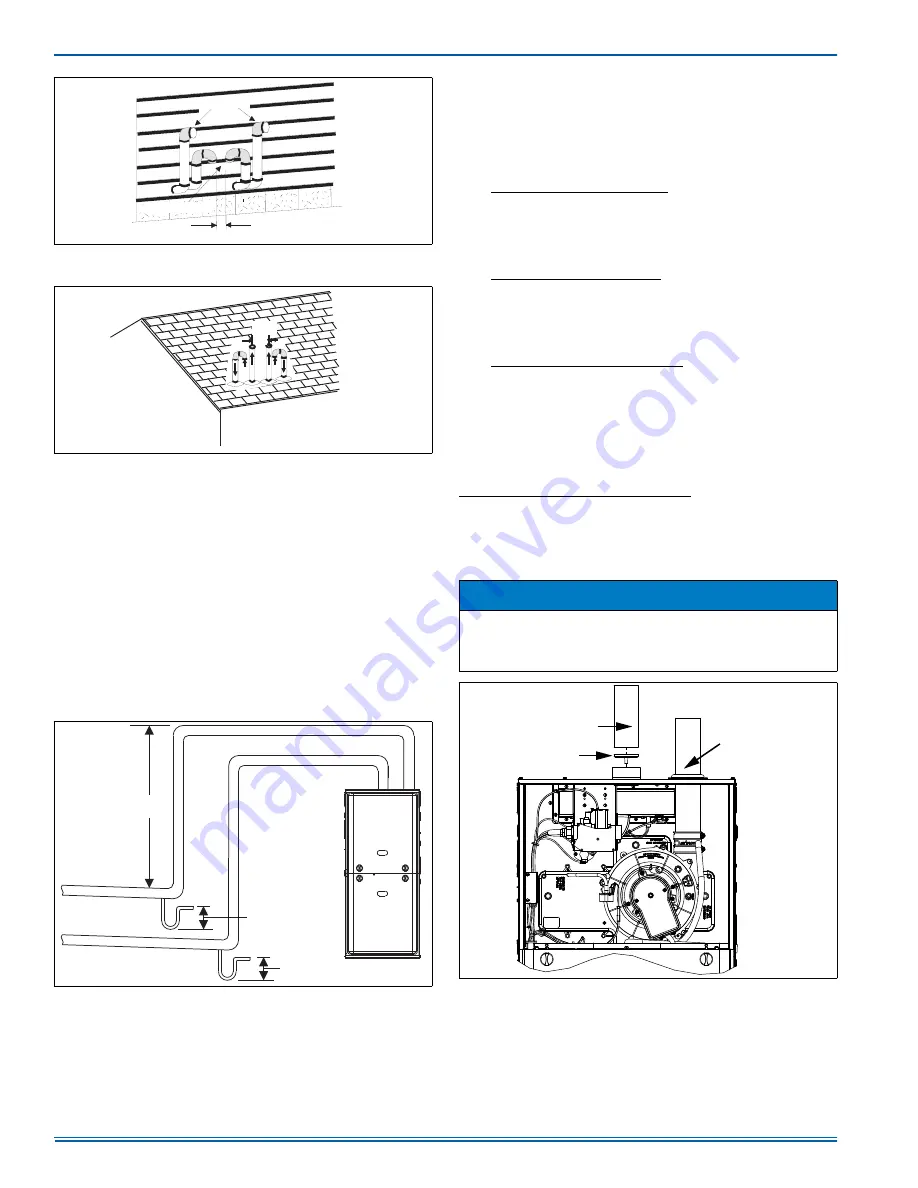

Figure 23:

Double Horizontal Combustion Air Intake and Vent

Termination

Figure 24:

Double Vertical Combustion Air Intake and Vent

Termination

Figure 25:

Downward Venting

VENT

2”

MIN.

COMBUSTION AIR

MIN.

6”

16’ MAX

6” MIN.

6” MIN.

NOTICE

An optional plastic birdscreen is shipped in the loose parts bag with

every furnace. This can be installed in the intake collar to prevent any

small objects from entering the furnace. The birdscreen cannot be

used if the intake drain is installed.

Figure 26:

Direct Vent Air Intake Connection and Vent Connection

AIR INTAKE PIPE

CONNECTS TO COLLAR

ON CASING TOP

INTAKE DRAIN

VENT PIPE

CLAMPS INTO

OUTLET OF

VENT COUPLING

RAIN GUTTER

A1130-001