YORK INTERNATIONAL

92

PUMPDOWN (LLSV) CONTROL

Each system has a Pumpdown feature upon shut-off.

On a non-safety, non-unit switch shutdown, all compres-

sors but one in the system will be shut off. The LLSV

will also be turned off. The final compressor will be al-

lowed to run until the suction pressure falls below the

cutout or for 180 seconds, which ever comes first.

Manual pumpdown from the keypad is not possible.

LOAD LIMITING

Load Limiting is a feature that prevents the unit from

loading beyond the desired value. 2 and 4 compressor

units can be load limited to 50%. This would allow only

1 compressor per system to run. 3 and 6 compressor

units can be load limited to 33% or 66%. The 66% limit

would allow up to 2 compressors per system to run,

and the 33% limit would allow only 1 compressor per

system to run. No other values of limiting are available.

There are two ways to load limit the unit. The first is

through remote communication via an ISN.

A second way to load limit the unit is through closing

contacts connected to the Load Limit (CTB1-Terminals

13-21) and PWM inputs (CTB1-Terminals 13-20). Stage

1 of load limiting involves closing the Load Limit input.

Stage 2 of load limiting involves closing both the Load

Limit and PWM inputs. The first stage of limiting is ei-

ther 66% or 50%, depending on the number of com-

pressors on the unit. The second stage of limiting is

33% and is only available on 3 and 6 compressor units.

Table 43 shows the load limiting permitted for the vari-

ous number of compressors.

NOTE: Simultaneous operation of Load Limiting and

EMS-PWM Temperature Reset (described on

following pages) cannot occur.

COMPRESSOR RUN STATUS

Compressor run status is indicated by closure of con-

tacts at CTB2 – terminals 25 to 26 for system 1 and

CTB2 – terminals 27 to 28 for system 2.

ALARM STATUS

System or unit shutdown is indicated by normally-open

alarm contacts opening whenever the unit shuts down

on a unit fault, or locks out on a system fault. System 1

alarm contacts are located at CTB2 - terminals 29 to

30. System 2 alarm contacts are located at CTB2 - ter-

minals 31 to 32. The alarm contacts will close when

conditions allow the unit to operate.

COMPRESSOR SEQUENCING

The unit control will attempt to equalize the total run

hours on individual compressors within a system. When

a system is about to start, the compressor with the least

run time in that system will be the first to start. When

the system has to load, the next compressor to start

will be the one with the least run time that is currently

not running in that system.

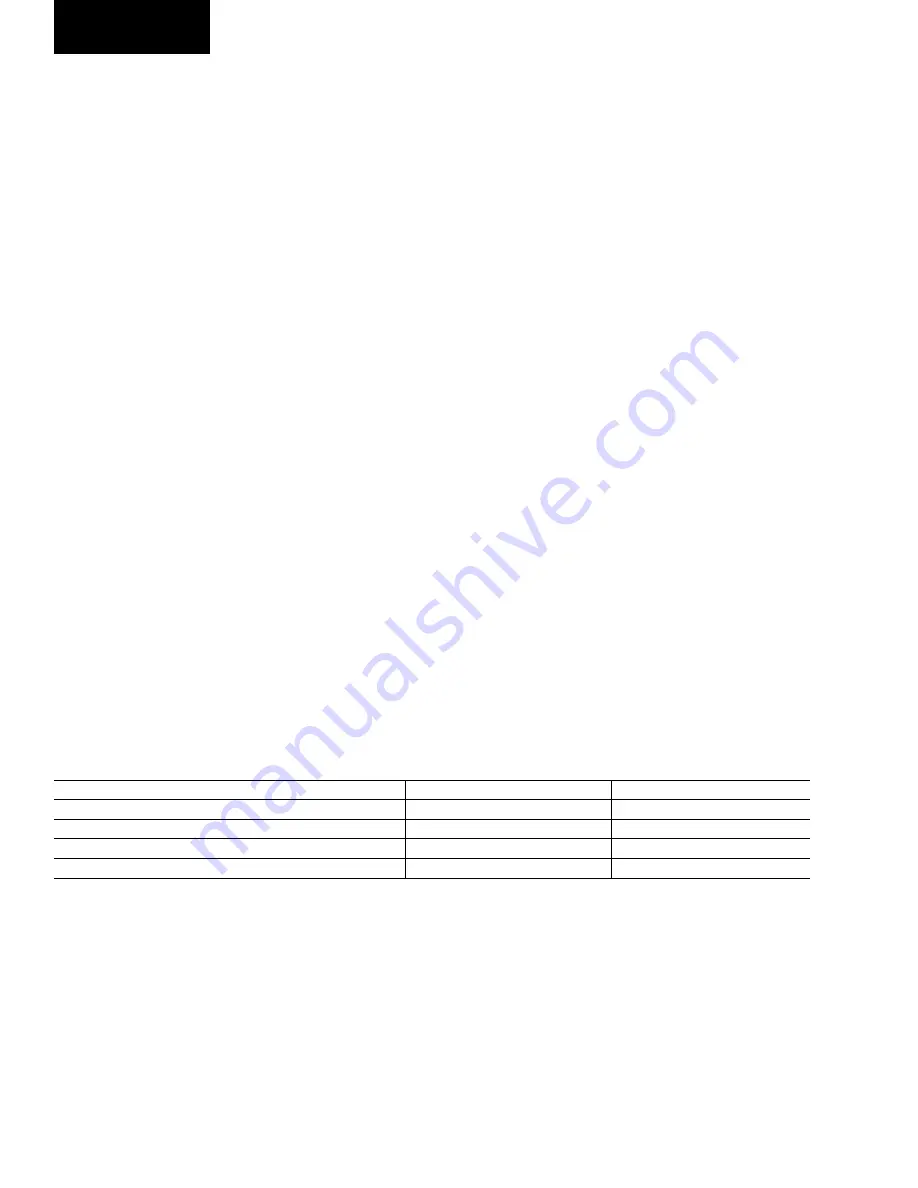

TABLE 43 – COMPRESSOR OPERATION – LOAD LIMITING

COMPRESSORS IN UNIT

STAGE 1

STAGE 2

2

50%

–

3

66%

33%

4

50%

–

6

66%

33%

Unit Controls

Summary of Contents for YCAL0014SC

Page 115: ...YORK INTERNATIONAL 115 FORM 150 62 NM1 This page intentionally left blank 4...

Page 116: ...YORK INTERNATIONAL 116 ELEMENTARY DIAGRAM YCAL0034SC FIG 13 ELEMENTARY DIAGRAM Wiring Diagrams...

Page 119: ...YORK INTERNATIONAL 119 FORM 150 62 NM1 This page intentionally left blank 4...

Page 130: ...APPENDIX 1 DIMENSIONS FIG 19 TYPE CP 1 FIG 20 TYPE CP 2 LD03839 LD03840 Appendix 1 Isolators...

Page 135: ...YORK INTERNATIONAL 135 FORM 150 62 NM1 This page intentionally left blank...