JOHNSON CONTROLS

12

FORM 150.67-NM2 (209)

General Chiller Introduction & Safety

Pressure Systems

The unit contains refrigerant vapor and liquid under

pressure, release of which can be a danger and cause

injury. The user should ensure that care is taken

during installation, operation and maintenance to

avoid damage to the pressure system. No attempt

should be made to gain access to the component parts

of the pressure system other than by suitably trained

and quali

fi

ed personnel.

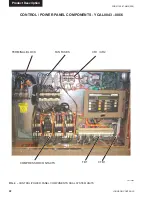

Electrical

The unit must be grounded. No installation or

maintenance work should be attempted on the

electrical equipment without

fi

rst switching power

OFF, isolating and locking-off the power supply.

Servicing and maintenance on live equipment must

only be performed by suitably trained and quali

fi

ed

personnel. No attempt should be made to gain access

to the control panel or electrical enclosures during

normal operation of the unit.

Rotating Parts

Fan guards must be

fi

tted at all times and not

removed unless the power supply has been isolated. If

ductwork is to be

fi

tted, requiring the wire fan guards

to be removed, alternative safety measures must be

taken to protect against the risk of injury from rotating

fans.

Sharp Edges

The

fi

ns on the air-cooled condenser coils have sharp

metal edges. Reasonable care should be taken when

working in contact with the coils to avoid the risk of

minor abrasions and lacerations. The use of gloves is

recommended.

Frame rails, brakes, and other components may also

have sharp edges. Reasonable care should be taken

when working in contact with any components to

avoid risk of minor abrasions and lacerations.

Refrigerants and Oils

Refrigerants and oils used in the unit are generally

nontoxic, non-

fl

ammable and non-corrosive, and pose

no special safety hazards. Use of gloves and safety

glasses is, however, recommended when working on

the unit. The build up of refrigerant vapor, from a

leak for example, does pose a risk of asphyxiation in

con

fi

ned or enclosed spaces and attention should be

given to good ventilation.

High Temperature and Pressure Cleaning

High temperature and pressure cleaning methods

(e.g. steam cleaning) should not be used on any part

of the pressure system as this may cause operation of

the pressure relief device(s). Detergents and solvents,

which may cause corrosion, should also be avoided.

Emergency Shutdown

In case of emergency, the control panel is

fi

tted

with a Unit Switch to stop the unit in an emergency.

When operated, it removes the low voltage 120

VAC electrical supply from the inverter system, thus

shutting down the unit.

Summary of Contents for YCAL0019

Page 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Page 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Page 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Page 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Page 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Page 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Page 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...