FORM 150.67-NM2 (209)

13

JOHNSON CONTROLS

2

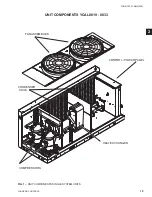

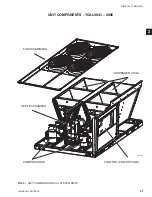

SECTION 2 – PRODUCT DESCRIPTION

INTRODUCTION

YORK Millennium

®

Air-Cooled Scroll Chillers provide

chilled water for all air con di tion ing ap pli ca tions using

central station air han dling or terminal units. They are

completely self-contained and are de signed for outdoor

(roof or ground lev el) in stal la tion. Each complete

packaged unit in cludes her met ic scroll com pres sors, a

liq uid cool er, air cooled con dens er, a charge of refrigerant

R-410A and a weather resistant microprocessor con trol

center, all mount ed on a pressed steel base.

The units are completely assembled with all

interconnecting refrigerant piping and internal wiring,

ready for

fi

eld installation.

Prior to delivery,

the packaged unit is pressure-tested,

evacuated, and fully charged with Refrigerant-R410A

and oil. After assembly, a complete operational test is

performed with water

fl

owing through the cooler to

assure that the refrigeration circuit operates correctly.

The unit structure is heavy-gauge, galvanized steel. This

galvanized steel is coated with baked-on powder paint,

which, when subjected to ASTM B117 1000 hour, salt

spray testing, yields a minimum ASTM 1654 rating of

“6”. Corrosion resistant wire mesh panels are added to

protect the condenser coil from incidental damage and

restrict unauthorized access to internal components.

Units are designed in accordance with NFPA 70

(National Electric Code), ASHRAE/ANSI 15 Safety

code for mechanical refrigeration, ASME, Listed and

labeled with Intertek Testing Services (ETL) and rated

in accordance with ARI Standard 550/590-2003.

All exposed power wiring is routed through liquid-

tight, non-metallic conduit.

GENERAL SYSTEM DESCRIPTION

Compressors

The chiller has suction-gas cooled, hermetic, scroll

compressors. The YCAL compressors incorporate

a compliant scroll design in both the axial and

radial direction. All rotating parts are statically and

dynamically balanced. A large internal volume and oil

reservoir provides greater liquid tolerance. Compressor

crankcase heaters are also included for extra protection

against liquid migration.

Evaporator (Heat Exchanger)

The Brazed Plate Heat Exchanger is equipped with a

heater controlled by the microprocessor. The heater

provides freeze protection for the cooler down to -

20 °F (-29 °C) ambient. The cooler is covered with

3/4” (19mm) flexible, closed-cell, foam insulation

(K~0.25).

Brazed plate heat exchangers shall be UL (Underwriters

Laboratories) listed. Installing contractor must include

accommodations in the chilled water piping to allow

proper drainage and venting of the heat exchanger. Water

inlet and outlet connections are grooved for compatibility

with factory supplied victaulic connections.

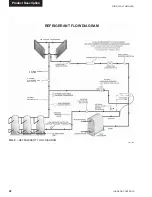

LD10950

DUAL CIRCUIT

Summary of Contents for YCAL0019

Page 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Page 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Page 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Page 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Page 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Page 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Page 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...