JOHNSON CONTROLS

14

FORM 150.67-NM2 (209)

Product Description

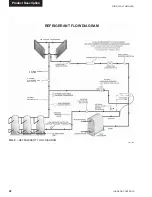

The heat exchanger is a brazed plate stainless steel

construction, single or dual circuit heat exchanger

capable of refrigerant working pressure of 650 PSIG

(3103 kPa) and liquid side pressure of 150 PSIG (1034

kPa) (Option for 300 PSIG [2068 kPa] available). Each

heat exchanger is covered in 3/4” (19mm)

fl

exible,

closed cell insulation, thermal conductivity of 0.26k

(BTU/HR-FT

2

– °F] /in) maximum.

A strainer with a mesh size between .5 and 1.5 mm (40

mesh) is recommended upstream of the heat exchanger

to prevent clogging.

Condenser

Coils

– Fin and tube condenser coils of seamless,

internally-enhanced, high-condensing-coefficient,

corrosion resistant copper tubes are arranged in

staggered rows, mechanically expanded into aluminum

fi

ns. Integral subcooling is included. The design working

pressure of the coil is 650 PSIG (45 bar).

Low Sound Fans

– The condenser fans are composed

of corrosion resistant aluminum hub and glass-

fi

ber

reinforced composite blades molded into a low noise

airfoil section. They are designed for maximum

ef

fi

ciency and are statically and dynamically balanced

for vibration free operation. They are directly driven

by independent motors, and positioned for vertical air

discharge. All blades are statically and dynamically

balanced for vibration-free operation. The fan guards

are constructed of heavy-gauge, rust-resistant, PVC

coated steel wire.

Motors

– The fan motors are Totally Enclosed Air-

Over (TEAO), direct drive, 6 pole, current protected.

They feature ball bearings that are double-sealed and

permanently lubricated.

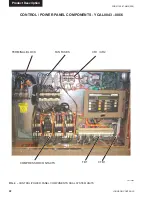

MILLENIUM CONTROL CENTER

All controls are contained in a NEMA 3R/12 (and

equiv a lent to IP55*) cabinet with hinged outer door

and in cludes:

Liquid Crystal Display with Light Emitting Diode back-

light ing for outdoor viewing:

• Two display lines

• Twenty characters per line

Color coded 12-button non-tactile key pad with sections

for:

DISPLAY/PRINT

of typical information:

•

Chilled liquid temperatures

• Ambient temperature

• System pressures (each circuit)

• Operating hours and starts (each compressor)

• Print calls up to the liquid crystal display

• Operating data for the systems

• History of fault shutdown data for up to

the last six fault shut down conditions.

• An RS-232 port, in conjunction with this

press-to-print button, is provided to permit

the capability of hard copy print-outs via a

separate printer (by others).

ENTRY

section to:

ENTER setpoints or modify system values.

SETPOINTS

updating can be performed to:

• Chilled liquid temperature setpoint and range

• Remote reset temperature range

• Set daily schedule/holiday for start/stop

• Manual override for servicing

• Low and high ambient cutouts

• Number of compressors

• Low liquid temperature cutout

• Low suction pressure cutout

• High discharge pressure cutout

• Anti-recycle timer (compressor start cycle

time)

• Anti-coincident timer (delay compressor

starts)

UNIT

section to:

• Set time

• Set unit options

UNIT ON/OFF

switch

The microprocessor control center is capable of

dis play ing the following:

• Return and leaving liquid temperature

• Low leaving liquid temperature cutout setting

• Low ambient temperature cutout setting

• Outdoor air temperature

• English or Metric data

Summary of Contents for YCAL0019

Page 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Page 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Page 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Page 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Page 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Page 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Page 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...