FORM 150.67-NM2 (209)

149

JOHNSON CONTROLS

7

Unit Trip Volts

For total chiller high current trip programming on

460VAC chillers:

• Add the sum of all the the compressor and

fan RLA’s in the chiller.

• Multiply the sum by 1.25

• Divide by 225A

• The resulting voltage is the value that should be

programmed.

For example, if fan and compressor RLA’s total 180A:

5V x 180A

x 1.25 =

1125VA

= 5.0V

225A 225A

The programmed value will be 5.0V.

R E M O T E U N I T I D

P R O G R A M M E D = X

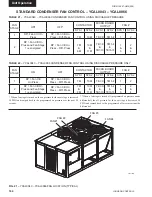

TABLE 13 –

* The minimum discharge pressure allowed is 235 PSIG. The Fan Differential Off Pressure High Limit will be lowered (reduced) to

prevent going below 235 PSIG based on where the fan control On Pressure is programmed.

PROGRAM VALUE

MODE

LOW LIMIT

HIGH LIMIT

DEFAULT

DISCHARGE PRESSURE CUTOUT

—

325 PSIG

575 PSIG

570 PSIG

22.4 BARG

39.6 BARG

39.3 BARG

SUCTION PRESSURE CUTOUT

WATER COOLING

80.0 PSIG

120.0 PSIG

80.0 PSIG

5.52 BARG

8.27 BARG

5.52 BARG

GLYCOL COOLING

42.0 PSIG

70.0 PSIG

44.0 PSIG

2.9 BARG

4.83 BARG

3.03 BARG

LOW AMBIENT TEMP. CUTOUT

STANDARD AMBIENT

25.0 °F

60.0 °F

25.0 °F

-3.9 °C

15.6 °C

-3.9 °C

LOW AMBIENT

0 °F

60.0 °F

25.0 °F

-17.8 °C

15.6 °C

-3.9 °C

LEAVING CHILLED LIQUID

WATER COOLING

—

—

36 °F

2.2 °C

TEMP. CUTOUT

GLYCOL COOLING

-1.0 °F

36.0 °F

36.0 °F

-18.3 °C

2.2 °C

2.2 °C

ANTI-RECYCLE TIMER —

300 SEC.

600 SEC.

600 SEC.

FAN CONTROL ON PRESSURE

—

360 PSIG

485 PSIG

385 PSIG

24.8 BARG

33.4 BARG

26.5 BARG

FAN DIFFERENTIAL OFF PRESSURE

—

80 PSID

160 PSID*

125 PSID

5.51 BARD

11.03 BARD*

8.62 BARD

TOTAL NUMBER OF COMPRESSORS

SINGLE

SYSTEM

2

3

3

DUAL

SYSTEM

4

6

6

NUMBER OF FANS PER SYSTEM

2 4

3

UNIT/SYSTEM TRIP VOLTS

CURRENT FEEDBACK

0.5 Volts

4.5 Volts

2.5 Volts

REMOTE UNIT ID

—

0

7

0

When communications is required with a BAS or

OptiView Panel, individual unit IDs are necessary for

communications with speci

fi

c chillers on a single RS-

485 line. ID 0-7 is selectable.

PROGRAM KEY LIMITS AND DEFAULT

Summary of Contents for YCAL0019

Page 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Page 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Page 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Page 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Page 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Page 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Page 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...