FORM 150.67-NM2 (209)

15

JOHNSON CONTROLS

2

• Suction pressure cutout setting

• Each system suction pressure

• Discharge pressure (optional)

• Liquid Temperature Reset via a YORK ISN DDC

or Building Automation System (by others) via:

- a pulse width modulated (PWM) input as stan

-

dard.

- a 4-20 milliamp or 0 -10 VDC input with the

optional B.A.S. interface option.

• Anti-recycle timer status for each system

• Anti-coincident system start timer condition

• Compressor run status

• No cooling load condition

• Day, date and time

• Daily start/stop times

• Holiday status

• Automatic or manual system lead/lag control

• Lead system definition

• Compressor starts & operating hours

(each compressor)

• Status of hot gas valves, evaporator heater

and fan operation

• Run permissive status

• Number of compressors running

• Liquid solenoid valve status

• Load & unload timer status

• Water pump status

Provisions are included for: pumpdown at shutdown;

optional remote chilled water temperature reset and

two steps of demand load limiting from an external

building automation system. Unit alarm contacts are

standard.

The operating program is stored in non-volatile

memory (EPROM) to eliminate chiller failure due to

AC powered failure/battery discharge. Programmed

setpoints are retained in lithium battery-backed RTC

memory for 5 years minimum.

* Intensity of Protection European Standard

** International Electrotechnical Commission

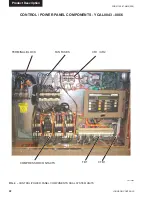

POWER PANEL

Each panel contains:

• Compressor power terminals

• Compressor motor starting contactors per

l.E.C.**

• Control power terminals to accept incoming for

115-1-60 control power

• Fan contactors & overload current protection

The power wiring is routed through liquid-tight

conduit to the compressors and fans.

Summary of Contents for YCAL0019

Page 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Page 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Page 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Page 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Page 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Page 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Page 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...