JOHNSON CONTROLS

176

FORM 150.67-NM2 (209)

Unit Operation

BAS/EMS TEMPERATURE RESET USING

A VOLTAGE OR CURRENT SIGNAL

The Remote Reset Option allows the Control Center

of the unit to reset the chilled liquid setpoint using a

0 - 10VDC input, or a 4-20mA input connected to CTB1

terminals A- and A+. Whenever a reset is called for, the

change may be noted by pressing the Cooling Setpoints

key twice. The new value will be displayed as “REM

SETP = XXX °F.”

If a

0 - 10VDC

signal is supplied, it is applied to

terminals A+ and A-, and

jumper JP1 on the I/O board

must be inserted between pins 2 and 3.

To calculate

the reset chilled liquid setpoint for values between 0VDC

and 10VDC use the following formula:

Setpoint = Local Chilled Liquid Se °Reset

Reset = (DC voltage signal) x (*Max Reset Value)

10

Example:

Local Chilled Liquid Setpoint = 45 °F (7.22 °C)

*Max Reset Value = 20 °F (11.11 °C)

Input Signal = 6VDC

(English)

Reset = 6VDC x 20 °F = 12

°F Reset

10

New Setpoint = 45 °F + 12 °F = 57 °F

(Metric)

Reset = 6VDC x 11. 11 °C = 6.67 °C Reset

10

New Setpoint = 7.22 °C + 6.67 °C = 13.89 °C

*

Max Reset Value is the “Max EMS-PWM Remote Temp. Reset” setpoint

value described in the program ming section under Cooling Setpoints.

Programmable values are from 2 °F to 40 °F (1.11 °C to 11.11

°C).

If a

4-20mA signal is supplied,

it is applied to terminals

A+ and A- and

jumper JP1 on the I/O board must be

installed between pin 1 and 2

. To calculate the chilled

liquid setpoint for values between 4mA and 20 mA use

the following formula:

Setpoint = Local Chilled Liquid Se °Reset

°Reset = (mA signal - 4) x (*Max Reset Value)

16

Example:

Local Chilled Liquid Setpoint = 45° (7.22 °C)

*Max Reset Value = 10 °F (5.56 °C)

Input Signal = 12 mA

(English)

°Reset = 8mA x 10 °F = 5 °F Reset

16

Setpoint = 45 °F + 5 °F = 50 °F

(Metric)

°Reset = 8mA x 5.56 °C = 2.78 °C Reset

16

Setpoint = 7.22 °C + 2.78 °C = 10.0 °C

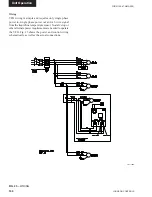

A 240-24 Volt Ratio Transformer (T3)

is used to derive nominal 12 volt output

from the 120 volt supply.

Summary of Contents for YCAL0019

Page 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Page 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Page 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Page 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Page 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Page 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Page 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...