FORM 150.67-NM2 (209)

33

JOHNSON CONTROLS

4

To ensure warranty coverage, this

equipment must be commissioned

and serviced by an authorized YORK

service mechanic or a qualifi ed service

person experienced in chiller instal-

lation. Installation must comply with

all applicable codes, particularly in

regard to electrical wiring and other

safety elements such as relief valves,

HP cutout settings, design working

pressures, and ventilation require-

ments consistent with the amount and

type of refrigerant charge.

Lethal voltages exist within the control

panels. Before servicing, open and tag

all disconnect switches.

INSTALLATION CHECKLIST

The following items, 1 through 5, must be checked

before placing the units in operation.

1. Inspect the unit for shipping damage.

2. Rig unit using spreader bars.

3. Open the unit only to install water piping system.

Do not remove protective covers from water con-

nections until piping is ready for attachment. Check

water piping to ensure cleanliness.

4. Pipe unit using good piping practice (see ASHRAE

handbook section 215 and 195).

5. Check to see that the unit is installed and operated

within limitations (Refer to LIMITATIONS).

The following pages outline detailed procedures to be

followed to install and start-up the chiller.

HANDLING

These units are shipped as completely assembled units

containing full operating charge, and care should be

taken to avoid damage due to rough handling.

SECTION 4 – INSTALLATION

INSPECTION

Immediately upon receiving the unit, it should be

inspected for possible damage which may have

occurred during transit. If damage is evident, it should

be noted in the carrier’s freight bill. A written request

for inspection by the carrier’s agent should be made at

once. See “Instruction” manual, Form 50.15-NM for

more information and details.

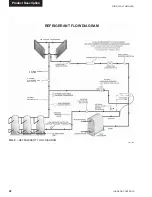

LOCATION AND CLEARANCES

These units are designed for outdoor installations on

ground level, rooftop, or beside a building. Location

should be selected for minimum sun exposure and to

insure adequate supply of fresh air for the condenser.

The units must be installed with suf

fi

cient clearances for

air entrance to the condenser coil, for air discharge away

from the condenser, and for servicing access.

In installations where winter operation is intended and

snow accumulations are expected, additional height must

be provided to ensure normal condenser air

fl

ow.

Clearances are listed under “Notes” in the

“DIMENSIONS” section.

Foundation

The unit should be mounted on a flat and level

foundation,

fl

oor, or rooftop capable of supporting

the entire operating weight of the equipment. See

PHYSICAL DATA for operating weight. If the unit is

elevated beyond the normal reach of service personnel,

a suitable catwalk must be capable of supporting service

personnel, their equipment, and the compressors.

Summary of Contents for YCAL0019

Page 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Page 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Page 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Page 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Page 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Page 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Page 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...