FORM 150.67-NM2 (209)

53

JOHNSON CONTROLS

5

5

ELECTRICAL NOTES AND LEGEND

VOLTAGE CODE

-50 = 380-3-50

Field Wiring

Factory Wiring

LEGEND:

1. Minimum Circuit Ampacity (MCA) is based on 125% of the rated load amps for the larg est motor plus 100% of

the rated load amps for all other loads included in the cir cuit, per N.E.C. Article 430-24. If the optional Factory

Mount ed Control Transformer is provided, add the following MCA values to the electrical tables for the system

providing power to the transformer: -17, add 2.5 amps; -28, add 2.3 amps; -40, add 1.5 amps, -46, add 1.3 amps;

-58, add 1 amps.

2. The minimum recommended disconnect switch is based on 115% of the rated load amps for all loads included

in the circuit, per N.E.C. Article 440.

3. Minimum fuse size is based upon 150% of the rated load amps for the largest motor plus 100% of the rated load

amps for all other loads included in the circuit to avoid nui sance trips at start-up due to lock rotor amps. It is not

recommended in ap pli ca tions where brown outs, frequent starting and stopping of the unit, and/or op er a tion at

am bi ent temperatures in excess of 95ºF (35ºC) is anticipated.

4. Maximum fuse size is based upon 225% of the rated load amps for the largest motor plus 100% of the rated

load amps for all other loads included in the circuit, per N.E.C. Article 440-22.

5. Circuit breakers must be UL listed and CSA certi

fi

ed and maximum size is based on 225% of the rated load amps

for the largest motor plus 100% of the rated load amps for all other loads included in the circuit. Oth er wise, an

HACR-type circuit breakers must be used. Maximum HACR circuit breaker rating is based on 225% of the rated

load amps for the largest motor plus 100% of the rated load amps for all other loads included in the circuit.

6. The “INCOMING WIRE RANGE” is the minimum and maximum wire size that can be ac com mo dat ed by the

unit wiring lugs. The (2) preceding the wire range indicates the number of termination points available per phase

of the wire range speci

fi

ed. Actual wire size and number of wires per phase must be determined based on the

National Elec tri cal Code,

using copper connectors only

. Field wiring must also comply with lo cal codes.

7. A ground lug is provided for each compressor system to accommodate a

fi

eld ground ing conductor per N.E.C.

Table 250-95. A control circuit grounding lug is also supplied.

8. The supplied disconnect is a “Disconnecting Means” as de

fi

ned in the N.E.C. 100, and is in tend ed for isolating the

unit for the available power supply to perform main te nance and troubleshooting. This disconnect is not intended

to be a Load Break De vice.

9. Field Wiring by others which complies to the National Electrical Code & Local Codes.

NOTES:

LEGEND:

ACR

ACROSS THE LINE START

C.B. CIRCUIT

BREAKER

D.E.

DUAL ELEMENT FUSE

DISC SW

DISCONNECT SWITCH

FACT MOUNT CB

FACTORY MOUNTED CIRCUIT BREAKER

FLA FULL

LOAD

AMPS

HZ HERTZ

MAX MAXIMUM

MCA MINIMUM

CIRCUIT

AMPACITY

MIN MINIMUM

MIN

MINIMUM NON FUSED

RLA RATED

LOAD

AMPS

S.P. WIRE

SINGLE POINT WIRING

UNIT MTD SERV SW UNIT MOUNTED SERVICE (NON-FUSED

DISCONNECT

SWITCH)

LRA LOCKED

ROTOR

AMPS

Summary of Contents for YCAL0019

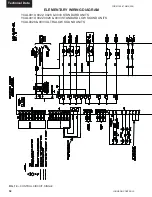

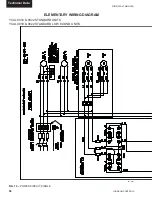

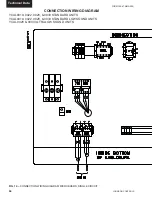

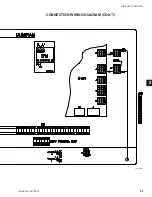

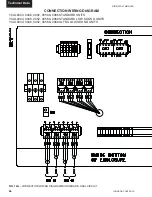

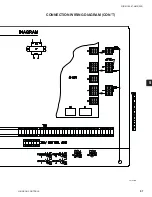

Page 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Page 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

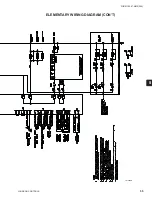

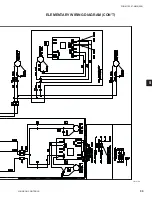

Page 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Page 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

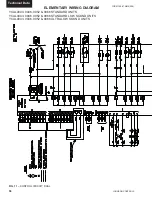

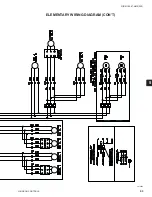

Page 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

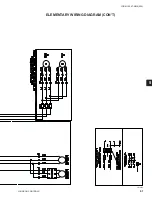

Page 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

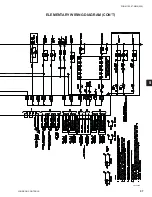

Page 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...