YORK INTERNATIONAL

18

FORM 201.19-W3 (1104)

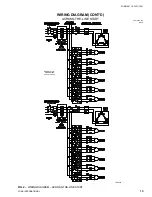

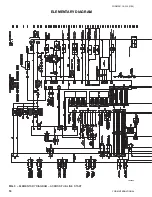

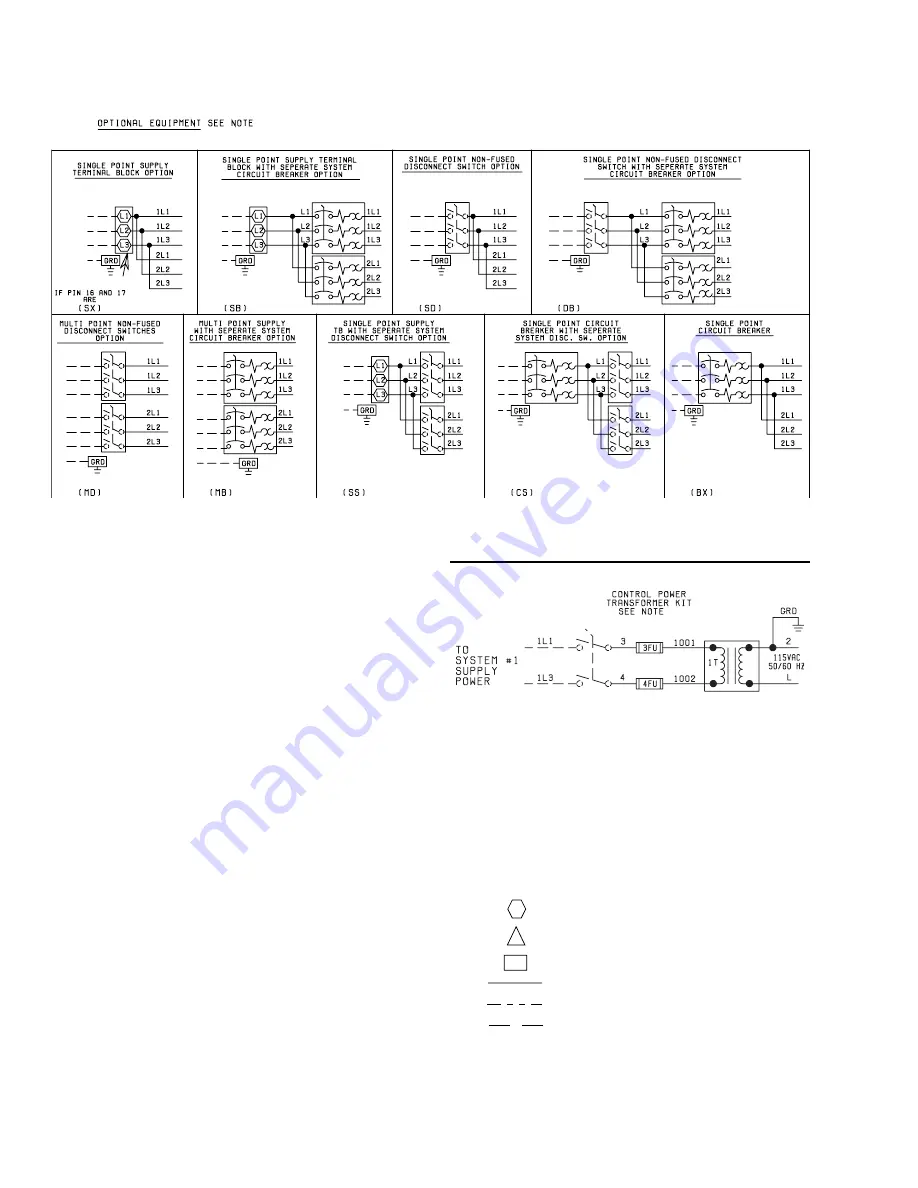

WIRING DIAGRAM

WYE-DELTA START

FIG. 4 –

WIRING DIAGRAM – WYE-DELTA START

NOTES:

1. Field wiring to be in accordance with the current edi tion of

the National Electrical Code as well as all oth er ap pli ca ble

codes and specifi cations.

2. Numbers along the right side of a diagram are line iden ti -

fi ca tion numbers. The numbers at each line in di cate the line

number lo ca tion of relay contacts. An unlined contact loca-

tion signifi es a nor mal ly closed contact. Numbers adjacent

to circuit lines are the cir cuit iden ti fi ca tion numbers.

3. Any customer supplied contacts must be suitable for

switching 24VDC. (Gold contacts rec om mend ed.) Con-

trol Wiring must not be run in the same conduit with any

line voltage wiring.

4. To cycle unit on and off automatically with contact

shown, install a cycling device in series with the fl ow

switch (FSLW). See Note 3 for contact rating and wiring

specifi cations. Also refer to cau tions on page 21.

5. To stop unit (Emergency Stop) with contacts other than

those shown, install the stop contact between 5 and 1. If

a stop device is not installed, a jumper must be con nect ed

between ter mi nals 5 and 1. De vice must have a min i mum

contact rating of 100VA at 115 volts A.C.

6. Alarm contacts are for annunciating alarm/unit mal func -

tion. Con tacts are rated at 115V, 100VA, re sis tive load only,

and must be suppressed at load by user.

7. See Installation, Operation and Maintenance Man u al when

op tion al equipment is used.

8. Control panel to be securely connected to earth ground.

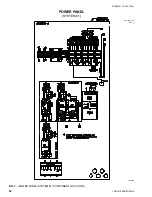

LEGEND

Transient Voltage Suppression

Terminal Block for Customer Connections

Terminal Block for Customer Low Voltage

(Class 2) Connections. See Note 2

Terminal Block for YORK Connections Only

Wiring and Components by YORK

Optional Equipment

Wiring and/or Components by Others

T S

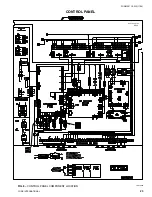

7.

LD09231

7.

LD09232

035 15164 103

REV F

Summary of Contents for YCAS Series

Page 5: ...YORK INTERNATIONAL 5 FORM 201 19 W3 1104 This page intentionally left blank...

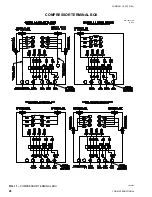

Page 25: ...YORK INTERNATIONAL 25 FORM 201 19 W3 1104 LEGEND LD010027...

Page 26: ...YORK INTERNATIONAL 26 FORM 201 19 W3 1104 LD03282 LD03283 LD03284 035 15164 102 REV E...

Page 31: ...YORK INTERNATIONAL 31 FORM 201 19 W3 1104 NOTES...