131

YORK INTERNATIONAL

FORM 201.19-NM6 (804)

#

5. Program the required op er at ing val ues into the

mi cro for cut-outs, safe ties, etc. and record them

in the chart be low. See Page 178 for details.

Record programmed values in the chart below.

PROGRAMMED VALUES

Display Language =_____________________________

Discharge Press Cutout = _______________ PSIG (kPa)

Discharge Press Unload = _______________ PSIG (kPa)

Suction Press Cutout = _________________ PSIG (kPa)

High Amb Cutout = ________________________ °F (°C)

Low Amb Cutout = _________________________ °F (°C)

Leaving Chilled Liquid Temp Cutout = __________ °F (°C)

High Motor Current Unload = _________________ % FLA

Anti-Recycle Time = ________________________ Secs

Local / Remote Mode = __________________________

Display Units = _ ___________________________

Lead / Lag Control = ____________________________

Power Failure Restart = _________________________

Suction Superheat Setpoint = _______________ °F (°C)

#

6. Program the Chilled Liquid Setpoint/Range and

record:

Setpoint = __________________ °F (°C)

Range = +/- ________________ °F (°C)

Keep in mind that the setpoint temperature dis-

played by the micro should equal the de sired

leav ing wa ter tem per a ture.

#

7. Assure that the CLK jumper J18 on the Mi cro -

pro ces sor Board is in the ON position (Top 2

pins).

#

8. Set the Time and Date.

#

9. Program the Daily Schedule start and stop

times.

#

10.Check the Factory Service Mode programming

values, (See Section 8.10) assure they are cor-

rect, and record the values:

Refrigerant Type = _____________ R22 Chiller Type =

Unit Type = __________________________________

Heat Recovery = _______________________________

Sys #1 100% FLA = _________________________Amps

Sys #2 100% FLA = _________________________Amps

Sys #3 100% FLA = _________________________Amps

Sys #4 100% FLA = _________________________Amps

#

16.

Assure that the Flow Switch is properly in-

stalled, wired correctly, and working.

#

17. Assure bolts through compressor feet to bottom

frame rails are removed.

PANEL CHECKS

(Power ON – Both System Switches “OFF”)

#

1. Apply 3-phase power and verify its val ue (See

Fig. 9 and 10 pages 34 and 35).

#

2. Apply 115VAC and verify its value on the ter-

mi nal block in the lower left of the Power Pan el.

Make the mea sure ment between ter mi nals 5 and

2 (See Fig. 14, page 39). The voltage should be

/- 10%.

#

3.

Assure the heaters on each compressor are on.

Al low the compressor heaters to remain on a

min i mum of 24 hours before start- up. This is

im por tant to as sure that no re frig er ant is in

the com pres sor oil at start-up!

#

4. Program the dip switches on the mi cro pro ces sor

board for the desired operating re quire ments. See

Fig. 78, Page 159. OPEN = Left side of switch

pushed down. CLOSED = Right side of switch

pushed down.

SWITCH

SWITCH "OPEN"

SETTING

SWITCH "CLOSED"

SETTING

1

Water Cooling

Glycol Cooling

2

Standard Ambient

Control

Low Ambient Control

3

Refrigerant R-407C

Refrigerant R-22

4

Do Not Use

YCAS

5

Do Not Use

Motor Current Av-

eraging (Start-Up)

Disabled

6

Heat Recovery

Disabled

Do Not Use

7

Expansion Valve

Thermostatic

Expansion Valve

Electronic*

8

Spare

Spare

*Expansion valve electronic should always be selected when an

EEV is installed.

Verify the selections by pressing the OP TIONS Key on

the control panel. Check them off in the chart above.

Damage to the chiller could

result if switch es are im prop er ly

pro grammed.

7

Summary of Contents for YCAS

Page 43: ...43 YORK INTERNATIONAL FORM 201 19 NM6 804 5 This page intentionally left blank...

Page 45: ...45 YORK INTERNATIONAL FORM 201 19 NM6 804 6 This page intentionally left blank...

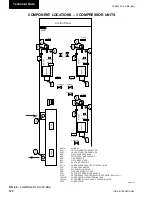

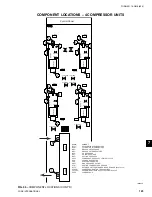

Page 65: ...65 YORK INTERNATIONAL FORM 201 19 NM6 804 7 LD09359 Electronic Panel 035 19205 104 Rev A...

Page 81: ...81 YORK INTERNATIONAL FORM 201 19 NM6 804 LD09378 CONNECTION WIRING DIAGRAM Electronic Panel...

Page 91: ...91 YORK INTERNATIONAL FORM 201 19 NM6 804 This page intentionally left blank...

Page 147: ...147 YORK INTERNATIONAL FORM 201 19 NM6 804 8 This page intentionally left blank...

Page 205: ...205 YORK INTERNATIONAL FORM 201 19 NM6 804 8 This page intentionally left blank...