140

YORK INTERNATIONAL

FORM 201.19-NM6 (804)

1.10 EMS/BAS

CONTROLS

The microprocessor system can accept remote signals

to Start/Stop the chiller, adjust maximum allowable run-

ning current for each compressor, and adjust the chilled

liquid leaving temperature setpoint. These func tions can

easily be controlled by connecting user sup plied “dry”

contacts to terminals in the control panel.

Remote Start/Stop

Remote Start/Stop can be accomplished using a time

clock, manual contact or other “dry” contact in series

with the fl ow switch which is connected to Terminals

13 and 14 in the logic section of the control pan el. The

contact must be closed to allow the chiller to run. Any

time this contact opens, the chill er will shut down and

the NO RUN PERM message will be dis played. The

lo ca tion of the fl ow switch connection is shown in Sec-

tion 1.12.

Nev er bypass a fl ow switch. This will

cause dam age to the chiller and void

any war ran ties.

Wir ing from remote “dry” contacts

(for stop/start and re set func tions)

should not ex ceed 25 ft. (8 m) and

should be run in ground ed con duit

that does not car ry any wiring other

than con trol wiring or shielded cable.

If an in duc tive device (re lay, contactor)

is sup ply ing these con tacts, the coil of

the de vice must be sup pressed with a

sup pres sor YORK Part Number 031-

00808-000 across the in duc tive coil.

Remote Current Reset

The maximum allowable running current for each com-

pres sor can be adjusted remotely to a lower value using

repeated timed closure of “dry” contacts connected to

Terminals 13 and 16 located in the logic section of the

control panel (See Section 1.12). The duration of the

contact clo sure will determine the amount of adjustment.

Gen er al ly, this input is used for purposes of demand limit

and operates as follows:

Closing the input contact for a defi ned period of time

allows reset of the % Cur rent Limit down ward. Con tact

closure of 1 - 11 seconds will allow % Current Lim it ing

to be ad just ed down ward from 105% by a max i mum

of 75%, i.e. to a minimum value of 30% FLA. EMS

Cur rent Lim it ing op er ates independently of the High

Av er age Cur rent Unload (See Sec tion 8.2). The micro

will always look at the two Cur rent Limit Set points and

choose the lower as the con trol ling val ue, when ev er

Remote Cur rent Lim it ing is uti lized. Con tact clo sures

of less than 1 sec ond will be ignored. A closure of 11

sec onds is the max i mum al low able clo sure and pro vides

a Current Limit re duc tion of 75%. The re mote reset cur-

rent can be cal cu lat ed as follows:

REMOTE

RESET

=

105% FLA

-

{(Contact Closed Time -1sec) x (75% FLA)}

CURRENT

10 sec

For example, after a 4 second pulse, the offset would

equal:

Remote Reset Curr = 105% FLA - {(4sec - 1 sec) X (75%FLA)}

10 sec

= 105% - 225%FLA sec

10 sec

= 82.5% FLA

To maintain a given offset, the contact clo sure signal

must be repeated (refreshed) every 30 seconds - 30

minutes. The refresh is not accerted sooner than 30

seconds from the end of the last PWM signal, but must

be refreshed before 30 minutes has elapsed. After 30

min utes, if no refresh is pro vid ed, the setpoint will

change back to its original val ue.

After an offset signal, the new Re mote

Current Limit may be viewed on the

EMS Current Lim it ing Dis play under

the Mo tor Current Key (see Sec tion

3.5). How ev er, if this dis play is being

viewed when the re set pulse oc curs, the

setpoint will not change on the dis play.

To view the new off set, fi rst press any

other dis play key on the key pad and

then press the Motor Current Key.

Remote EMS Reset will not operate

when a Re mote Control Center Op-

tion Kit is con nect ed to the mi cro.

The Re mote Con trol Center will al ways

de ter mine the setpoint.

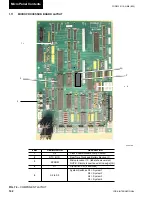

Micro Panel Contents

Summary of Contents for YCAS

Page 43: ...43 YORK INTERNATIONAL FORM 201 19 NM6 804 5 This page intentionally left blank...

Page 45: ...45 YORK INTERNATIONAL FORM 201 19 NM6 804 6 This page intentionally left blank...

Page 65: ...65 YORK INTERNATIONAL FORM 201 19 NM6 804 7 LD09359 Electronic Panel 035 19205 104 Rev A...

Page 81: ...81 YORK INTERNATIONAL FORM 201 19 NM6 804 LD09378 CONNECTION WIRING DIAGRAM Electronic Panel...

Page 91: ...91 YORK INTERNATIONAL FORM 201 19 NM6 804 This page intentionally left blank...

Page 147: ...147 YORK INTERNATIONAL FORM 201 19 NM6 804 8 This page intentionally left blank...

Page 205: ...205 YORK INTERNATIONAL FORM 201 19 NM6 804 8 This page intentionally left blank...