18

JOHNSON CONTROLS

FORM 201.21-NM3 (616)

PRODUCT DESCRIPTION

The power section of the drive is composed of four

major blocks consisting of an AC to DC rectifier section

with accompanying pre-charge circuit, a DC link filter

section, a three phase DC to AC inverter section, and

an output suppression network.

The AC to DC rectifier

utilizes a semi-converter formed

by the connection of three SCR/diode modules (1SCR-

3SCR) in a three phase bridge configuration. The mod

-

ules are mounted on a liquid cooled heatsink. Use of the

semi-converter configuration permits implementation

of a separate pre-charge circuit to limit the flow of cur

-

rent into the DC link filter capacitors when the drive is

switched on and it also provides a fast disconnect from

the power mains when the drive is switched off. When

the drive is turned off, the SCRs in the semiconverter

remain in a non-conducting mode and the DC link filter

capacitors

remain uncharged. When the drive is com-

manded to run, the DC link filter capacitors are slowly

charged via the semi-converter. The SCR’s are then

gated fully on.

Three power fuses (1FU - 3FU), an optional circuit

breaker (1SW) and a standard 5% impedance minimum

3 phase line reactor connect the AC to DC converter to

the incoming power. Very fast semiconductor power

fuses are utilized to ensure that the SCR/diode module

packages do not rupture if a catastrophic failure were to

occur on the DC link. The SCR Trigger board provides

the gating pulses for the SCR’s as commanded by the

VSD Logic board.

The DC Link filter

section of the drive consists of a

group of electrolytic filter capacitors (C1-C6). This ca

-

pacitor bank effectively smooths the ripple voltage from

the AC to DC rectifier while simultaneously providing a

large energy reservoir for use by the DC to AC inverter

section of the drive. In order to achieve the required

voltage capability for the capacitor portion of the filter,

filter capacitor “banks” are formed by connecting two

groups of parallel capacitors in series to form a capaci-

tor “bank”. In order to assure an equal sharing of the

voltage between the series connected capacitors and to

provide a discharge means for the capacitor bank when

the VSD is powered off, “bleeder” resistors (1RES and

2RES) are connected across the capacitor banks.

The DC to AC inverter

section of the VSD serves to

convert the rectified and filtered DC back to AC at the

magnitude and frequency commanded by the VSD Logic

board. The inverter section is actually composed of two

to four identical inverter output phase assemblies. These

assemblies are in turn composed of 3 pairs of Insulated

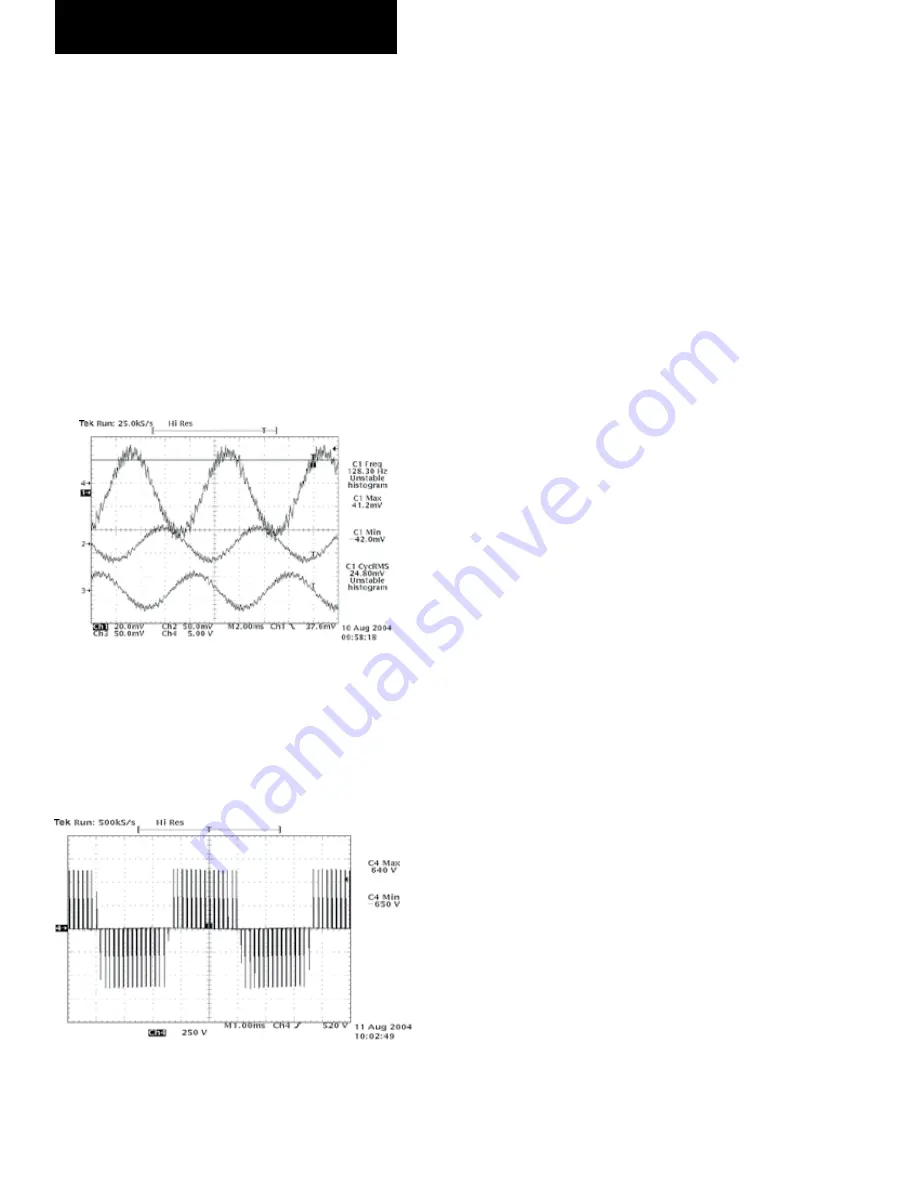

FIG. 2 - PWM VOLTAGE WAVEFORM

LD10480

Variable Speed Drive (VSD)

The VSD (variable speed drive) is a liquid cooled,

transistorized, PWM inverter, which provides speed

control to vary the speed of 2, 3 or 4 compressor motors.

The VSD changes the duration of the voltage pulses

supplied to the motor to enable control of compressor

speed to match the system load. A PWM generator, on

the VSD Logic Board, with a switching frequency of

3125 Hz modulates the voltage signal to provide a rela-

tively constant V/F ratio. In some cases, the V/F ratio

is slightly modified to provide additional torque to the

motor. Sample 3 phase current waveforms are shown

in FIG. 1 to show the sinusoidal characteristics of the

current drawn by the compressor motors.

FIG. 1 - PWM CURRENT WAVEFORM

LD10479

A Sample PWM voltage waveforms is shown in FIG.

2. The pulses near the sides of the rectangular groups

of waves are notably narrower, representing the lower

voltage of a sinusoidal waveform as it rises or falls from

the “0” crossing.

Summary of Contents for YCAV0267E

Page 61: ...61 JOHNSON CONTROLS FORM 201 21 NM3 616 This intentionally left blank 6 ...

Page 73: ...73 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank 6 ...

Page 89: ...89 JOHNSON CONTROLS FORM 201 21 NM3 616 6 035 20890 009 REV LOCATION LABEL CON T LD11141 ...

Page 146: ...146 JOHNSON CONTROLS FORM 201 21 NM3 616 TECHNICAL DATA This page intentionally left blank ...

Page 147: ...147 JOHNSON CONTROLS FORM 201 21 NM3 616 6 This page intentionally left blank ...

Page 247: ...247 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank ...

Page 269: ...269 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank 8 ...

Page 289: ...289 JOHNSON CONTROLS FORM 201 21 NM3 616 8 This page intentionally left blank ...

Page 317: ...317 JOHNSON CONTROLS FORM 201 21 NM3 616 8 This page intentionally left blank ...

Page 348: ...348 JOHNSON CONTROLS FORM 201 21 NM3 616 MAINTENANCE NOTES ...

Page 349: ...349 JOHNSON CONTROLS FORM 201 21 NM3 616 9 NOTES ...