196

JOHNSON CONTROLS

FORM 201.21-NM3 (616)

TECHNICAL DATA

The Chiller Control Board is the controller and

master decision maker in the control panel. The on-

board microprocessor control is capable of controlling

up to 4 compressors. System inputs from pressure

transducers and temperature sensors are connected

directly to the Chiller Control Board. The Chiller

Control Board circuitry multiplexes all of the analog

inputs, digitizes them, and scans the inputs to keep a

constant watch on chiller operating conditions. Based

on this information, the Chiller Control Board issues

commands to the Relay Output Board(s), Drain/Feed

Valve Controller, and VSD Logic Board to activate

and de-activate contactors, solenoids, control valves,

set compressor speeds, etc., for chilled liquid and

safety control. Keypad commands are acted upon by

the Chiller Control Board micro to change setpoints,

cutouts, scheduling, operating requirements, and to

provide displays.

The Chiller Control Board contains a Real Time Clock

integrated circuit chip with an internal battery back up

of 8K x 8 bit RAM. The purpose of the battery backed

RAM is to assure any programmed values (setpoints,

clock, cutouts, history data etc.) are not lost during a

power failure, regardless of the time involved in a power

outage or shutdown period.

The Chiller Control (Microprocessor) Board contains an

onboard power supply, which provides 5VDC regulated

to sensors, transducers, display, and other circuit boards.

The supply also pr12VDC to the Relay Output

Boards and the +34VDC to the level sensors.

The Chiller Control Board is capable of directly

receiving analog inputs from temperature sensors and

transducers. An analog to digital converter (A/D) with

an onboard 4 channel multiplexer (MUX) allows up to

48 analog inputs to be read. The A/D Converter converts

the analog signals to digital signals, which can be read

by the onboard microprocessor. On a 2 system chiller,

approximately half of these inputs are utilized.

Three integrated circuits on the microprocessor can be

configured for digital inputs or outputs (Digital I/O).

As inputs, they can read digital (2 level, on/off) inputs

like keypad keys, unit switch, high pressure cut-out,

flow switch, etc. As outputs they are used for controls

like turning on fans, controlling compressor heaters,

controlling chiller valves, or other devices requiring

on/off control. Up to 72 Digital I/O will be utilized to

control the chiller.

The Chiller Control (Microprocessor) Board contains

a dual UART (Universal Asynchronous Receiver

Transmitter) for RS-485 and RS-232 communications.

UART1 is configured for RCC and ISN communica

-

tions on the external chiller RS-485 port. Data is sent

and received at 4800 baud with 1 start bit, 8 data bits,

odd parity, and 1 stop bit. The port is shared with the

RS-232 interface and at start-up will be initialized to

RS-485 communications. UART2 is configured for

VSD communications over an internal chiller RS-485

port located within the Control/Power cabinet. UART2

has a higher priority interrupt than UART1. The data

is sent and received at a rate of 9600 baud and serves

only as the communications between the Chiller Control

Board and the VSD Logic Board. Both of these boards

are located within the Control/Power panel.

On power-up, the Chiller Control Board will attempt to

initialize communications with the VSD Logic Board.

The Chiller Control Board will request the number of

compressors select and VSD software version. If for

some reason the information is not provided, the request

will be made over and over again until it is received.

Once the data has been received, the Chiller Control

Board will not ask for it again. If the communications

is not established, a VSD Loss Of Comms fault message

will appear on the STATUS display.

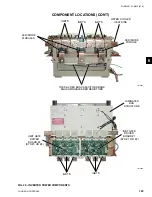

CHILLER CONTROL BOARD

50079

RTC

CHILLER ELECTRONIC COMPONENTS (CON'T)

Summary of Contents for YCAV0267E

Page 61: ...61 JOHNSON CONTROLS FORM 201 21 NM3 616 This intentionally left blank 6 ...

Page 73: ...73 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank 6 ...

Page 89: ...89 JOHNSON CONTROLS FORM 201 21 NM3 616 6 035 20890 009 REV LOCATION LABEL CON T LD11141 ...

Page 146: ...146 JOHNSON CONTROLS FORM 201 21 NM3 616 TECHNICAL DATA This page intentionally left blank ...

Page 147: ...147 JOHNSON CONTROLS FORM 201 21 NM3 616 6 This page intentionally left blank ...

Page 247: ...247 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank ...

Page 269: ...269 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank 8 ...

Page 289: ...289 JOHNSON CONTROLS FORM 201 21 NM3 616 8 This page intentionally left blank ...

Page 317: ...317 JOHNSON CONTROLS FORM 201 21 NM3 616 8 This page intentionally left blank ...

Page 348: ...348 JOHNSON CONTROLS FORM 201 21 NM3 616 MAINTENANCE NOTES ...

Page 349: ...349 JOHNSON CONTROLS FORM 201 21 NM3 616 9 NOTES ...