JOHNSON CONTROLS

112

FORM 201.23-EG1 (1013)

data for last ten shutdown faults. Compressor suc

-

tion, discharge, and oil pressures and temperatures,

suction and discharge superheats, percent of full-load,

operating hours, starts, and anti-recycle timer status.

Status Messages for manual override, unit switch off,

compressor run, run permissive, remote controlled

shut down, no cooling load, daily/holiday shut down,

anti-recycle timer.

E. Predictive Control Points: Unit controls shall avoid

safety shutdown when operating outside design con

-

ditions by optimizing the chiller controls and cooling

load output to stay online and avoid safety limits be-

ing reached. The system shall monitor the following

parameters and maintain the maximum cooling output

possible without shutdown of the equipment: motor

current, suction pressure and discharge pressure.

F. System Safeties: Shall cause individual compressor

systems to perform auto-reset shut down; manual reset

required after the third trip in 90 minutes. Includes:

high discharge pressure or temperature, low suction

pressure, high / low motor current, high motor tem

-

perature, high pressure switch, high / low differential oil

pressure, high oil temperature, low suction superheat,

critical sensor malfunction, low or high current, phase

loss/single phase power, overload of motor windings,

and low voltage.

G. Unit Safeties: Shall be automatic reset and cause

compressors to shut down if: high or low ambient, low

leaving chilled liquid temperature, under voltage, and

flow switch operation. Contractor shall provide flow

switch and wiring per chiller manufacturer require

-

ments.

H. Manufacturer shall provide any controls not listed

above, necessary for automatic chiller operation. Me

-

chanical Contractor shall provide field control wiring

necessary to interface sensors to the chiller control

system.

2.07 ACCESSORIES and OPTIONS

Some accessories and options supersede standard prod-

uct features. Your Johnson Controls representative will be

pleased to provide assistance.

A. Sound Reduction

1. Provide the following options as required to meet

scheduled sound performance data at all load

points.

a. Normal speed fans and unlined compressor

enclosure. (

Factory Mounted

)

b. Two-speed fans and acousticallly lined enclo

-

sure. (

Factory Mounted

)

c. Sound power octave band data, dB per AHRI

standard 70 and IAW ISO3744 at 35°C ambi

-

ent and 7°C leaving chilled water.

2. Provide optional control input to limit sound out-

put of the chiller based on time of day. Shall be

programmable at the chiller panel or controlled

remotely via signal (4-20mA or 0-10 VDC) from

BAS system. Chillers without this feature shall

be provided with the necessary sound attenua

-

tion to meet the scheduled sound performance

data at all load points.

B. Power Supply/Connections:

1. Circuit breaker is optional at point of incoming

single point connection to provide disconnect-

ing means AND be sized to provide the motor

branch circuit protection, short circuit protec

-

tion and ground fault protection for the motor

branch-circuit conductors, the motor control

apparatus and the motors. Circuit breaker shall

be equipped with lockable operating handle that

shall extend through power panel door so that

power may be disconnected without opening any

panel doors.

C. Condenser Coil Environmental Protection:

1.

PRE-COATED FIN CONDENSER COILS –

The air-cooled condenser coils are constructed

of epoxy-coated aluminum fins.

2.

COPPER FIN –

Provide condenser coils with

copper fins in lieu of aluminum fins.

3.

POST-COATED EPOXY DIPPED CONDENSER

COILS –

The unit is built with dipped-cured con

-

denser coils.

D. Protective Chiller Panels (

Factory Mounted

):

1. Louvered Panels (condenser coils only): Painted

steel to match unit panels, over external condenser

coil faces.

2. Wire Panels (full unit): Heavy gauge, welded wire

mesh, coated to resist corrosion, to protect con

-

denser coils from incidental damage and restrict

unauthorized access to internal components.

3. Louvered Panels (full unit): Painted steel to

match unit panels, to protect condenser coils

from incidental damage, visually screen internal

components, and prevent unauthorized access

to internal components.

4. Louvered/Wire Panels: Louvered steel panels on

external condenser coil faces, painted to match

Guide Specifications

Summary of Contents for YCIV0177S/P

Page 57: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 57...

Page 59: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 59...

Page 61: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 61...

Page 63: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 63...

Page 65: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 65...

Page 67: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 67...

Page 69: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 69...

Page 71: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 71...

Page 73: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 73...

Page 75: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 75...

Page 77: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 77...

Page 89: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 89 INTENTIONALLY LEFT BLANK...

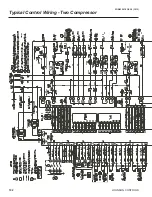

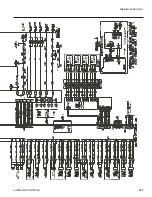

Page 102: ...JOHNSON CONTROLS 102 FORM 201 23 EG1 1013 Typical Control Wiring Two Compressor...

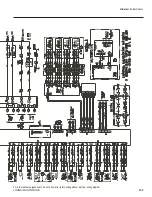

Page 104: ...JOHNSON CONTROLS 104 FORM 201 23 EG1 1013 Typical Control Wiring Three Compressor...

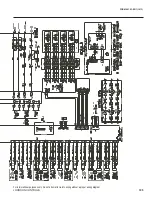

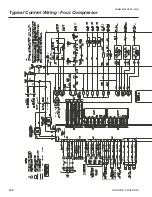

Page 106: ...JOHNSON CONTROLS 106 FORM 201 23 EG1 1013 Typical Control Wiring Four Compressor...

Page 107: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 107...

Page 114: ...Form 201 23 EG1 1013 Supersedes 201 23 EG1 713...