JOHNSON CONTROLS

98

FORM 201.23-EG1 (1013)

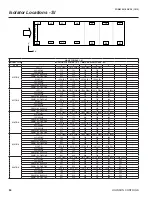

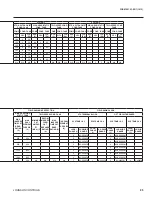

LEGEND

C.B.

CIRCUIT BREAKER

D.E.

DUAL ELEMENT FUSE

DISC SW

DISCONNECT SWITCH

FACT CB

FACTORY-MOUNTED CIRCUIT BREAKER

FLA

FULL LOAD AMPS

HZ HERTZ

MAX MAXIMUM

MCA

MINIMUM CIRCUIT AMPACITY

MIN MINIMUM

MIN NF

MINIMUM NON-FUSED

RLA

RATED LOAD AMPS

S.P. WIRE

SINGLE-POINT WIRING

Electrical Notes

NOTES:

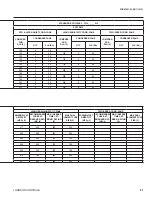

1. U.L. Label is provided on 50 and 60 Hz units for these electrical wiring configurations.

2. –– –– –– –– –– –– Dashed Line = Field Provided Wiring.

3. The above recommendations are based on the National Electric Code and using copper conductors only. Field wiring must also comply

with local codes. Group Rated breaker must be HACR type for cUL machines.

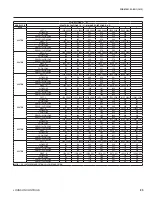

1. As standard, all 2 and 3 compressor units have single point power connections. The YCIV0457PA/

YCIV1649PA has dual point power connection as standard. Contact factory for information regarding

dual point power 2 and 3 compressor units.

2. Maximum Inverse Time Circuit Breaker or Dual Element Fuse - 225% of the largest compressor RLA

plus the sum of all other loads per NEC 440.22 (A).

3. MCA - Minimum Circuit Ampacity - 125% of the largest compressor RLA plus 100% of the remaining

compressor RLA's plus the sum of all condenser fan FLA's per NEC 440.33

4. Recommended time delay or dual element fuse size - 150%of the largest compressor RLA plus 100%

of the remaining compressor RLA's plus the sum of all condenser fan FLA's.

5. RLA - Rated Load Amps - rated in accordance with UL standard 1995.

6. Local codes may take precedence.

7. Control KVA includes operational controls and evaporator heaters.

8. System inrush current is less than RLA due to the use of York Variable Speed Drive technology. Typical

Compressor Starting Current ( first four seconds of startup):

Rated Voltage Typical Starting Current per Compressor

380-400/50/3

28A

380/60/3

29A

460/60/3

23A

9. Voltage Utilization Range:

Rated Voltage

Utilization Range

380-415/50/3

360 - 440

380/60/3

342 - 402

460/60/3

414 - 508

Summary of Contents for YCIV0177S/P

Page 57: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 57...

Page 59: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 59...

Page 61: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 61...

Page 63: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 63...

Page 65: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 65...

Page 67: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 67...

Page 69: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 69...

Page 71: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 71...

Page 73: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 73...

Page 75: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 75...

Page 77: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 77...

Page 89: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 89 INTENTIONALLY LEFT BLANK...

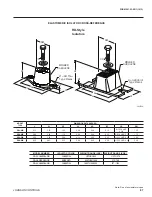

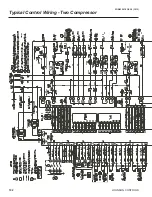

Page 102: ...JOHNSON CONTROLS 102 FORM 201 23 EG1 1013 Typical Control Wiring Two Compressor...

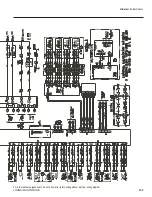

Page 104: ...JOHNSON CONTROLS 104 FORM 201 23 EG1 1013 Typical Control Wiring Three Compressor...

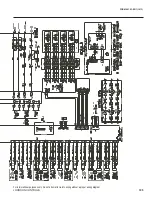

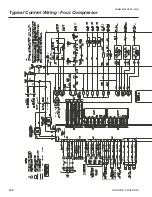

Page 106: ...JOHNSON CONTROLS 106 FORM 201 23 EG1 1013 Typical Control Wiring Four Compressor...

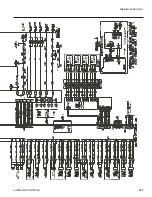

Page 107: ...JOHNSON CONTROLS FORM 201 23 EG1 1013 107...

Page 114: ...Form 201 23 EG1 1013 Supersedes 201 23 EG1 713...