FORM 150.24-NM27

YORK INTERNATIONAL

47

The COMP RUNNING message indicates that the re-

spective compressor is running due to demand.

The anti-recycle timer message shows the amount of

time left on the respective anti-recycle timer. This mes-

sage is displayed when demand requires the respective

system to start but is being held off due to the timer.

The anti-coincident timer is a software feature that guards

against 2 compressors starting simultaneously. This

assures instantaneous starting current does not become

excessively high due to simultaneous starts. The micro

limits the time between compressor starts to 1 minute

regardless of demand of the anti-recycle timer being timed

out. The time shown on the anti-coincident timer is the

time left on the timer before the respective system will

start. Demand must be present for the message to be

displayed and will only appear when the anti-recycle timer

has timed out.

This display informs the operator that the micro is limit-

ing the loading of the system based on motor current.

By programming the AVERAGE CURR UNLOAD point,

the micro will limit the loading of the compressor when-

ever motor current rises above the programmed value.

This feature reduces the chance of a system faulting on

high motor current, motor protector due to motor over-

heating, or high discharge pressure which causes high

motor current. The feature also assures that motor life is

not compromised. Typically, the AVERAGE CURR UN-

LOAD is programmed for 100% to assure that the com-

pressor is allowed to load to its rated FLA.

The Suction Pressure Limiting message indicates a sys-

tem is being unloaded by the micro even though demand

requires loading. This safety assures that refrigerant re-

turning to the compressor provides proper motor cooling,

assuring that motor life is not compromised. This safety

will only activate when the chilled liquid temperature is

excessively high. Unloading will take place when suction

pressure exceeds the user programmable threshold of

80-105 PSIG. Reloading will take place when suction pres-

sure drops to 10 PSIG below the safety threshold.

Discharge Pressure Limiting takes affect when discharge

pressure nears the point at which the high pressure

cut-out will shut the system down causing total loss of

cooling. When this message appears, discharge pres-

sure has exceeded the user programmable threshold and

the micro is unloading the affected system to prevent

shutdown on a manual high pressure cut-out. Reloading

will take place when discharge pressure has dropped 60

PSIG below the threshold.

Optional discharge pressure transducers must be in-

stalled for this feature to operate. This is accomplished

by adding the Discharge Pressure Readout option.

The PUMPING DOWN message indicates that the re-

spective compressor is presently in the process of pump-

ing the system down. The compressor will either be in a

recycling pumpdown or in a pumpdown prior to shut-

down when this message is displayed. The message

will disappear when the compressor shuts off.

If the MANUAL OVERRIDE key is pressed, the STATUS

display will display the message shown above. This will

indicate that the Daily Schedule is being ignored and

the chiller will start-up when water temperature allows,

UNIT Switch permits, and SYSTEM Switches permit.

This is a priority message and cannot be overridden by

anti-recycle messages, fault messages, etc. when in

the STATUS Display mode. Therefore, do not expect to

see any other STATUS messages when in the MANUAL

OVERRIDE mode. MANUAL OVERRIDE is to only be

used in emergencies or for servicing.

FAULT STATUS MESSAGES

Whenever a fault message appears, the safety thresh-

olds on the chiller have been exceeded and the entire

chiller or a single system will be shut down and locked

out. A detailed explanation of the shutdown thresholds

and associated information related to each fault is cov-

ered in the SYSTEM SAFETIES section (Page 68).

Chiller shutdown faults will shut the entire chiller down and

lock it out, while system shutdown faults will only shut

down and lock out the affected system (compressor).

A list of the fault messages are shown on the next two pages:

S Y S # 1

A R

T M R

X X X

S

S Y S # 2

A R

T M R

X X X

S

S Y S # 1

A C

T M R

X X

S

S Y S # 2

A C

T M R

X X

S

M A N U A L

O V E R R I D E

S Y S # 1

S U C T

L I M I T I N G

S Y S # 2

S U C T

L I M I T I N G

* *

S Y S # 1

D S C H

L I M I T I N G

S Y S # 2

D S C H

L I M I T I N G

S Y S # 1

C R N T

L I M I T I N G

S Y S # 2

C R N T

L I M I T I N G

*

S Y S # 1

P U M P I N G

D O W N

S Y S # 2

P U M P I N G

D O W N

* *

* This message only applies to chillers with 031-01096-001 and early versions of 031-01652-001 EPROMs.

** This message only applies to chillers with later versions of 031-01652-001 (CRCP Version) EPROMs.

Summary of Contents for YCRJ45E00

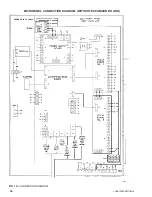

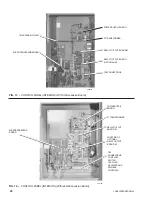

Page 29: ...FORM 150 24 NM27 YORK INTERNATIONAL 29 CONTROL CIRCUIT With I O Expansion Board LD02106 ...

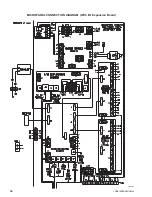

Page 30: ...30 YORK INTERNATIONAL FIG 9 SYSTEM WIRING ...

Page 31: ...FORM 150 24 NM27 YORK INTERNATIONAL 31 LD02678 ...

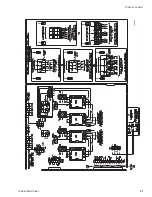

Page 35: ...FORM 150 24 NM27 YORK INTERNATIONAL 35 LD02679 ...

Page 36: ...36 YORK INTERNATIONAL MICROPANEL CONNECTION DIAGRAM With I O Expansion Board LD02107 ...

Page 37: ...FORM 150 24 NM27 YORK INTERNATIONAL 37 LD02108 ...