FORM 150.24-NM27

YORK INTERNATIONAL

93

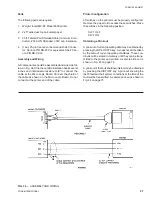

CONDENSER WATER PUMP CONTACT /

RUN STATUS OPTION

This option provides a dry contact which can be used

to turn on the condenser water pump, other device, or

indicate run status. The contact closes whenever one of

the compressors start.

Connections to this contact can be made on Terminals

21 and 22 of TB1 in the power panel. The location of

these terminals is shown in Fig. 30.

This option utilizes a second Relay Output Board and

associated wiring. The part number for the Field Mounted

Pump Control Kit is 471-01232-101. This kit is not re-

quired if a second Relay Output Board is already installed.

NOTE: Any inductive devices (contactor/relay coil) con-

nected to these contacts must be suppressed

with YORK P/N 031-00808-000 supplied by

others. Otherwise, nuisance faults may occur.

OPTIONS

for closer examination by factory service person-

nel is indicated.

H. If the oil is clean and free of metal particles, refill the

compressor with YORK C oil. To add oil or to fill the

compressor crankcase, connect the delivery tube of

the YORK Hand Oil Pump. YORK Part No. 470-10654

or equal to the compressor oil charging and drain

valve. Expel all air from the delivery tube by pumping

it full of oil, allowing a few drips to drip out before

tightening the flare nut to the oil charging valve. Then

open the oil charging valve and pump oil into the crank-

case to the proper level. It is necessary that the suc-

tion end of the hand oil pump be kept submerged

under the oil level in the container at all times, to

avoid entrance of air into the compressor.

I. Before opening the suction or discharge stop valves,

connect a vacuum pump to the pumpout port in the

discharge stop valve. (Pumpout port is port on valve

stem side of valve). With the vacuum line shutoff

valve open, run the vacuum pump until a vacuum of

at least 1000 microns is reached. Stop the vacuum

pump, close the shut-off valve and open the dis-

charge valve fully before disconnecting the line from

the vacuum pump. Disconnect the vacuum pump

and replace the plug in the pumpout port.

NOTE: If suction or discharge valves are not seated

properly, a 1000 micron vacuum can not be ob-

tained. Do not evacuate for long periods of time.

J. Be sure both discharge and suction stop valves

are open before operating the unit.

4. Suction and Discharge Valves and Springs The con-

dition of the suction and discharge valves and springs

should be checked by YORK service personnel on a

yearly basis or every 5000 hours, whichever comes

first.

This section is devoted to options which may be ordered or retrofitted to the unit. Listed below are the options which

are covered in this section.

1. CONDENSER WATER PUMP CONTACT/ RUN STATUS OPTION

2. CONDENSER WATER TEMP READOUT

3. HOT GAS BYPASS (LOADMINDER) OPTION

4. DISCHARGE PRESSURE READOUT OPTION

5. LOCAL PRINTER OPTION

6. BAS INTERFACE OPTION (REMOTE RESET OPTION)

FIG. 30

CONDENSER WATER PUMP CONTACT

CONNECTION POINT

LD02097

Summary of Contents for YCRJ45E00

Page 29: ...FORM 150 24 NM27 YORK INTERNATIONAL 29 CONTROL CIRCUIT With I O Expansion Board LD02106 ...

Page 30: ...30 YORK INTERNATIONAL FIG 9 SYSTEM WIRING ...

Page 31: ...FORM 150 24 NM27 YORK INTERNATIONAL 31 LD02678 ...

Page 35: ...FORM 150 24 NM27 YORK INTERNATIONAL 35 LD02679 ...

Page 36: ...36 YORK INTERNATIONAL MICROPANEL CONNECTION DIAGRAM With I O Expansion Board LD02107 ...

Page 37: ...FORM 150 24 NM27 YORK INTERNATIONAL 37 LD02108 ...