FORM 150.24-NM27

YORK INTERNATIONAL

95

2. Adjust the pilot power assembly adjustment screw

2 to approximately the middle of its adjustment

range.

3. The chiller must be running and stabilized on the

minimum stage capacity. In establishing this condi-

tion, it may be necessary to deactivate the regulator

by de-energizing the solenoid 1 .

4. Adjust the adjustment screw 2 in the clockwise

direction to open the valve at a higher pressure

(sooner) or in the counterclockwise direction to open

the valve at a lower pressure (slower response). The

valve is feeding when the valve outlet feels warm to

the touch.

The adjustment is correct when system suction pres-

sure rises to a point nearly equal to normal running

pressure at the midpoint in the Control Zone.

5. Further minor adjustment may be necessary to be

certain that the valve opens fully before the tempera-

ture point at which the compressor stops due to a

fall in Return or Leaving Water Temp.

6. Repeat this procedure on the other system.

NOTE: HOT GAS should not be considered as an addi-

tional step of unloading when programming the

number of steps of loading/unloading.

FIELD INSTALLATION

If it becomes necessary to field install the Hot Gas

(Loadminder) Option, two kits are required. Order the kit

from Table 3.

TABLE 3

KIT, HOT GAS BYPASS

MODEL

PART NO.

YCWJ45EE

375-05358-001

YCWJ55HE

375-05358-001

YCWJ56HF

375-05358-001

YCWJ66KH

375-05358-001

YCWJ67KH

375-05358-002

YCWJ77KH

375-05358-003

YCWJ88MH

375-05358-003

YCWJ99MJ

375-05358-004

YCRJ45E0

375-05886-001

YCRJ55H0

375-05886-001

YCRJ56H0

375-05886-001

YCRJ66H0

375-05886-001

YCRJ67K0

375-05886-002

YCRJ77K0

375-05886-002

YCRJ88M0

375-05886-003

YCRJ99M0

375-05886-004

In addition, a 471-01232-101 kit must also be ordered.

The 471-01232-101 kit consists of a second Relay Out-

put Board. It is not required if two Relay Boards are al-

ready installed in the control panel.

DISCHARGE PRESSURE READOUT OPTION

The Discharge Pressure Read-out Option P/N 471-

01266-131 allows the user to obtain control panel dis-

plays of discharge pressure. Additionally, other displays

such as fault information will then hold relevant discharge

pressure information useful in diagnosing problems.

The discharge pressure unloading feature also becomes

usable when this option is installed (Page 52) as well as

fan cycling by discharge pressure.

The kit consists of discharge pressure transducers for

each system, wire harnesses, and associated mounting

hardware.

LOCAL PRINTER OPTION

The Micro Panel is capable of supplying a print-out of

chiller conditions or fault shutdown information at any

given time. This allows operator and service personnel

to obtain data and system status with the touch of the

keypad. In addition to manual print selection, the micro

panel will provide an automatic print-out whenever a fault

occurs. An explanation of the keypad use to obtain a

print-out is discussed in the PRINT KEY Section on

Page 74.

YORK recommends the field tested WEIGH-TRONIX

IMP-24, Model 2600 printer. This is a compact low cost

printer that is ideal for service work and data logging.

Paper is in the form of a compact roll and is easily handled

compared to larger printers using wider business form

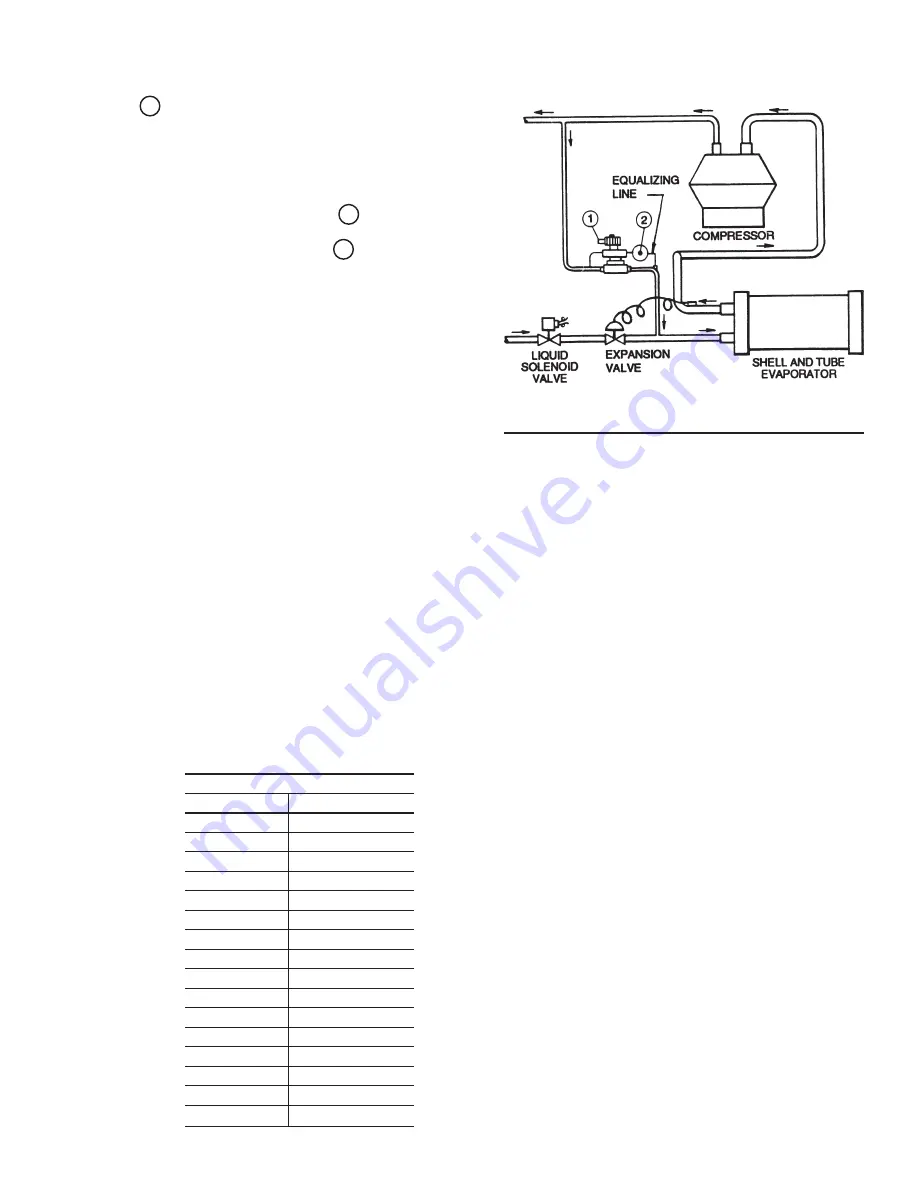

LD02099

FIG. 31

PIPING DIAGRAM

Summary of Contents for YCRJ45E00

Page 29: ...FORM 150 24 NM27 YORK INTERNATIONAL 29 CONTROL CIRCUIT With I O Expansion Board LD02106 ...

Page 30: ...30 YORK INTERNATIONAL FIG 9 SYSTEM WIRING ...

Page 31: ...FORM 150 24 NM27 YORK INTERNATIONAL 31 LD02678 ...

Page 35: ...FORM 150 24 NM27 YORK INTERNATIONAL 35 LD02679 ...

Page 36: ...36 YORK INTERNATIONAL MICROPANEL CONNECTION DIAGRAM With I O Expansion Board LD02107 ...

Page 37: ...FORM 150 24 NM27 YORK INTERNATIONAL 37 LD02108 ...