FORM 201.26-NM1

ISSUE DATE: 1/19/2018

JOHNSON CONTROLS

33

4

SECTION 4 – INSTALLATION

To ensure warranty coverage, this equip-

ment must be commissioned and serviced

by an authorized Johnson Controls

service mechanic or a qualified service

person experienced in chiller installation.

Installation must comply with all appli-

cable codes, particularly in regard to elec-

trical wiring and other safety elements

such as relief valves, HP cutout settings,

design working pressures, and ventilation

requirements consistent with the amount

and type of refrigerant charge.

Lethal voltages exist within the control

panels. Before servicing, open and tag

all disconnect switches.

INSTALLATION CHECKLIST

The following items, 1 through 5, must be checked be-

fore placing the units in operation.

1. Inspect the unit for shipping damage.

2. Rig unit using spreader bars.

3. Open the unit only to install water piping sys-

tem. Do not remove protective covers from water

connections until piping is ready for attachment.

Check water piping to ensure cleanliness.

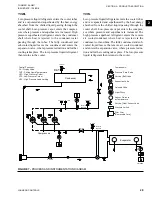

4. Pipe unit using good piping practice

(see ASHRAE

handbook Section 215 and 195).

5. Check to see that the unit is installed and operated

within limitations

(refer to LIMITATIONS in SEC-

The following pages outline detailed procedures to be

followed to install and start-up the chiller.

LOCATION REQUIREMENTS

To achieve optimum performance and trouble-free ser-

vice, it is essential that the proposed installation site

meets with the location and space requirements for

the model being installed. For dimensions, weight and

space requirements, including service access details,

refer to

The clearances recommended are nomi-

nal for the safe operation and mainte-

nance of the unit and power and control

panels. Local health and safety regula-

tions, or practical considerations for

service replacement of large components,

may require larger clearances than those

given in Section 5.

Units should be installed indoors where they are not

exposed to rain or water splash. Chillers should be lo-

cated near a drain. The use of chillers in corrosive,

dusty or explosive atmospheres should be avoided un-

less the unit is properly protected. A unit in a clean

room will run best, require least maintenance, and last

longest. Heat or ventilation may be required to main-

tain the ambient between 40°F and 115°F (4.4°C and

46.1°C).

Units are designed for indoor installation and not in-

tended for wet, corrosive or explosive atmospheres.

Installation should allow for water drain, ventilation

and sufficient clearance for service, including tube

cleaning.

UNIT ISOLATION (NOISE SENSITIVE

LOCATION)

For installation in equipment rooms near noise-critical

areas, common walls should be of adequate sound at-

tenuating construction, all doors should be tightly gas-

keted, and the unit should have vibration isolators fit-

ted.

FOUNDATION

The unit must be installed on a suitable flat and level

concrete base that extends to fully support the unit base

frame. The chiller foundation must be rigid to reduce

vibration transmission to a minimum. All upper story

installations should use vibration isolators under the

unit base. To maintain isolator efficiency, no mechani-

cal ties should be made to the building. Properly se-

lected flexible connectors and piping isolators are rec-

ommended. All the above recommendations will help

to reduce vibration transmission and ‘result in a quieter

operation.

On basement foundations remove a portion of the base-

ment floor so that a concrete base can be poured resting

on the ground, with a corkboard installed on both sides,

and a waterproof sealing compound.

Summary of Contents for YCWL0056SE

Page 4: ...FORM 201 26 NM1 ISSUE DATE 1 19 2018 JOHNSON CONTROLS 4 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 30: ...FORM 201 26 NM1 ISSUE DATE 1 19 2018 JOHNSON CONTROLS 30 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 146: ...FORM 201 26 NM1 ISSUE DATE 1 19 2018 JOHNSON CONTROLS 146 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 154: ...FORM 201 26 NM1 ISSUE DATE 1 19 2018 JOHNSON CONTROLS 154 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 168: ...FORM 201 26 NM1 ISSUE DATE 1 19 2018 JOHNSON CONTROLS 168 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 186: ...FORM 201 26 NM1 ISSUE DATE 1 19 2018 JOHNSON CONTROLS 186 NOTES...