YORK INTERNATIONAL

102

SECTION 11

DECOMMISSIONING, DISMANTLING AND DISPOSAL

Never release refrigerant to the atmo-

sphere when emptying the refrigerat-

ing circuits. Suitable retrieval equip-

ment must be used. If reclaimed re-

frigerant cannot be reused. It must be

returned to the manufacturer.

Never discard used compressor oil, as

it contains refrigerant in solution. Re-

turn used oil to the oil manufacturer.

Unless otherwise indicated, the operations described

below can be performed by any properly trained main-

tenance technician.

GENERAL

Isolate all sources of electrical supply to the unit in-

cluding any control system supplies switched by the

unit. Ensure that all points of isolation are secured in

the ‘OFF’ position. The supply cables may then be dis-

connected and removed. For connection points refer to

Section 4.

Remove all refrigerant from each system of the unit

into a suitable container using a refrigerant reclaim or

recovery unit. This refrigerant may then be re-used, if

appropriate, or returned to the manufacturer for dis-

posal. Under NO circumstances should refrigerant be

vented to atmosphere. Drain the oil from each system

into a suitable container and dispose of according to

local laws and regulations governing the disposal of

oily wastes. Any spilt oil should be mopped up and

similarly disposed of.

Isolate the unit heat exchangers from the external wa-

ter systems and drain the heat exchanger section of the

systems. If no isolation valves are installed it may be

necessary to drain the complete system.

If glycol or similar solutions have

been used in the water system, or

chemical additives are contained, the

solution MUST be disposed of in a

suitable and safe manner. Under NO

circumstances should any system con-

taining glycol or similar solutions be

drained directly into domestic waste

or natural water systems.

After draining, the water pipework can be disconnected

and removed.

Units can generally be removed in one piece after dis-

connection as above. Any mounting bolts should be

removed and then the unit should be lifted from posi-

tion using the points provided and equipment of ad-

equate lifting capacity.

Reference should be made to Section 4 for unit instal-

lation instructions, Section 9 for unit weights and Sec-

tion 3 for handling.

Units which cannot be removed in one piece after dis-

connection as above must be dismantled in position. Spe-

cial care should be taken regarding the weight and han-

dling of each component. Where possible units should

be dismantled in the reverse order of installation.

Residual refrigerant oil and glycol or

similar solutions may remain in some

parts of the system. These should be

mopped up and disposed of as de-

scribed above.

It is important to ensure that whilst components are

being removed the remaining parts are supported in a

safe manner.

Only use lifting equipment of ad-

equate capacity.

After removal from position the unit parts may be dis-

posed of according to local laws and regulations.

DECOMMISSIONING, DISMANTLING AND DISPOSAL

Summary of Contents for YCWS0313SC

Page 12: ...YORK INTERNATIONAL 12 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT...

Page 36: ...YORK INTERNATIONAL 36 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN PAGE FORMAT Commissioning...

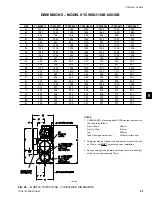

Page 86: ...YORK INTERNATIONAL 86 TYPICAL CONTROL PANEL WIRING Maintenance...

Page 87: ...FORM 201 24 NM2 87 YORK INTERNATIONAL TYPICAL CONTROL PANEL WIRING LD06957 8...

Page 103: ...FORM 201 24 NM2 103 YORK INTERNATIONAL NOTES 11...