JOHNSON CONTROLS

14

FORM 160.69-O2

ISSUE DATE: 9/30/2020

SECTION 1 – DESCRIPTION OF SYSTEM AND FUNDAMENTALS OF OPERATION

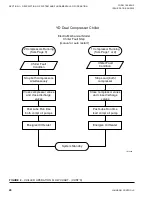

Normal or Single Compressor Mode

(Software version C.OPT.11.03.01.004 (or later))

The COMPRESSOR MODE Setpoint, available on the

Capacity Compressor Cycling Screen, is used to se-

lect either NORMAL Mode or SINGLE COMPRES-

SOR Mode. In Normal Mode, the second compressor

is brought on line to meet the load requirement as de-

scribed previously. In Single Compressor Mode, op-

eration is restricted to one compressor. The Lag com-

pressor will not be brought on line, regardless of the

load requirement.

When starting the chiller in Single Compressor mode,

the operator does not designate which compressor will

run. Rather, the “Lead” compressor is automatically

selected by the software per the present software op-

eration. The software to select the “Lead” compressor

has not changed.

If Single Compressor Mode is selected while both

compressors are running, a soft shutdown is performed

on the “Lag” compressor. All faults for this inhibited

compressor are continued to be handled.

If the chiller is shutdown while running in Single Com-

pressor mode, the software selects the “Lead” com-

pressor as it normally does on a subsequent restart.

COMPRESSOR SHUTDOWN

There are two types of shutdowns performed on one

or both compressors; Soft Shutdowns and Fault shut-

downs.

During a Soft Shutdown, first the Pre-rotation Vanes

are driven closed. When the Vanes have fully closed

(or 210 seconds have elapsed, whichever occurs first),

the Discharge Valve is then driven closed. When the

Discharge Valve has fully closed (or 40 seconds have

elapsed, whichever occurs first), the run signal to the

compressor motor starter is de-energized and the com-

pressor enters “Coastdown”. If any Discharge Valve

does not close within 40 seconds, a cycling shutdown

is performed and “Discharge #X – Valve Not Closed”

is displayed.

If the Lag compressor is taken off line due to a Low

Load condition while both compressors are running (as

explained above), a Soft Shutdown is performed on the

Lag compressor.

If one of the following shutdowns is initiated, a Soft

Shutdown is performed simultaneously on all running

compressors:

• Operator Initiated Soft Shutdown at Keypad

• “Remote Stop”

• “Leaving Chilled Liquid temperature – Low Tem-

perature”

• “Discharge Valve X – Valve Not Closed”

• “Multiunit – Contacts Open”

• “System Cycling (1 & 2) – Contacts Open”

• “Control panel – Schedule”

If any faults other than those listed above occur during

a Soft shutdown, the Soft Shutdown is aborted, the run

signal to the compressor motor starter is de-energized

and the compressor(s) immediately enters “Coast-

down”.

If an Operator initiates a “Local Stop” with the Keypad

Rocker Switch or any fault occurs other than those list-

ed immediately above, a Fault Shutdown is performed

on all running compressors. Simultaneously, the run

signal to the compressor motor starter(s) is de-ener-

gized, the compressor(s) enters “Coastdown”, and the

Pre-rotation Vanes and Discharge Valve(s) are driven

closed.

Summary of Contents for YD A

Page 8: ...JOHNSON CONTROLS 8 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 22: ...JOHNSON CONTROLS 22 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 28: ...JOHNSON CONTROLS 28 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 34: ...JOHNSON CONTROLS 34 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 48: ...JOHNSON CONTROLS 48 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...