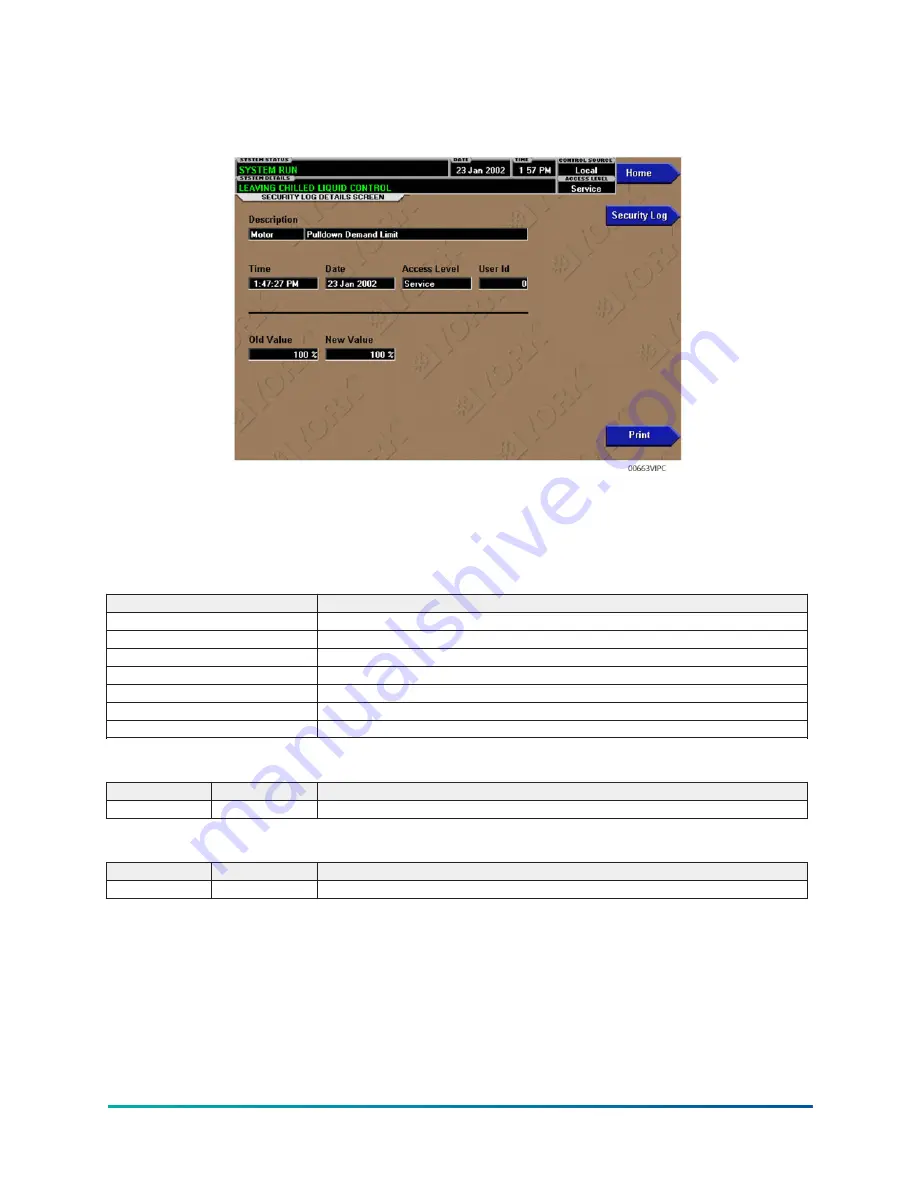

Security log details screen

Figure 48: Security log screen

This screen allows the user to view the details of a logged setpoint change, selected from the list

on the Security Log Screen. The date and time the setpoint was changed, the new and old setpoint

value and access level and user ID used to make the change are displayed. The data on this screen

can be printed. Requires a login access level of SERVICE.

Table 119: Display only fields

Field/LED name

Description

Description

Displays the setpoint/category that was changed.

Time

Displays the time the setpoint was changed.

Date

Displays the date the setpoint was changed.

Access level

Displays the login access level used to make the setpoint change.

User ID

Displays the login User ID used to make the setpoint change.

Old value

Displays the previous setpoint value.

New value

Displays the value entered at the time of the setpoint change.

Table 120: Programmable

Button

Access level

Description

Service

Generates a report of change parameters displayed.

Table 121: Navigation

Button

Access level

Description

Security log

Service

Returns to the Security Log screen.

115

Model YD Mod D with OptiView Control Center

Summary of Contents for YD Mod D

Page 2: ...2 Model YD Mod D with OptiView Control Center...

Page 8: ...Nomenclature Model YD Mod D with OptiView Control Center 8...

Page 17: ...Figure 2 Chiller operation flow chart 17 Model YD Mod D with OptiView Control Center...

Page 18: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 18...

Page 19: ...Figure 2 Chiller operation flow chart 19 Model YD Mod D with OptiView Control Center...

Page 20: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 20...

Page 21: ...Figure 2 Chiller operation flow chart 21 Model YD Mod D with OptiView Control Center...

Page 22: ...Figure 2 Chiller operation flow chart Model YD Mod D with OptiView Control Center 22...

Page 150: ...Figure 57 Sample printout status Model YD Mod D with OptiView Control Center 150...

Page 151: ...Figure 57 Sample printout status 151 Model YD Mod D with OptiView Control Center...

Page 152: ...Figure 58 Sample printout setpoints Model YD Mod D with OptiView Control Center 152...

Page 153: ...Figure 58 Sample printout setpoints 153 Model YD Mod D with OptiView Control Center...

Page 154: ...Figure 59 Sample printout schedule Model YD Mod D with OptiView Control Center 154...

Page 155: ...Figure 60 Sample printout sales order 155 Model YD Mod D with OptiView Control Center...

Page 156: ...Figure 61 Sample printout history Model YD Mod D with OptiView Control Center 156...

Page 157: ...Figure 61 Sample printout history 157 Model YD Mod D with OptiView Control Center...

Page 159: ...Figure 64 Sample printout custom screen report 159 Model YD Mod D with OptiView Control Center...