FORM 150.75-NM2

17

YORK INTERNATIONAL

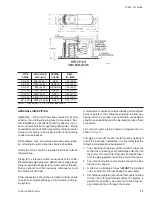

LD01922

TYPE

MAX. LOAD

SPRING

DEFL

& SIZE

LBS. (KG)

COLOR

IN. (MM)

CP-2-25

900 (408.2)

RED

1.22 (30.9)

CP-2-26

1200 (544.3)

PURPLE

1.17 (29.7)

CP-2-27

1500 (680.4)

ORANGE

1.06 (26.9)

CP-2-28

1800 (816.4)

GREEN

1.02 (25.9)

CP-2-31

2200 (997.9)

GRAY

0.83 (21.0)

CP-2-32

2600 (1179.3)

WHITE

0.74 (18.7)

CP-2-35

1

3000 (1360.8)

GOLD

0.70 (17.7)

NOTE: 1. Free height 1/2" (12.7) higher than shown.

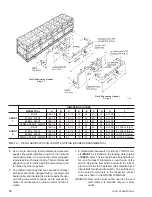

GENERAL LIQUID PIPING

GENERAL When liquid has been located in its final

position, the unit liquid piping may be connected. Nor-

mal installation precautions should be observed in or-

der to receive maximum operating efficiencies. Piping

should be kept free of all foreign matter. All liquid cooler

piping must comply in all respects with local plumbing

codes and ordinances.

Since elbows, tees, and valves decrease pump capac-

ity, all piping should be kept as simple as possible.

Hand stop valve should be installed in all lines to facili-

tate servicing.

Piping to the inlet and outlet connections of the chiller

should include high-pressure rubber hose or piping loops

to insure against transimission of water pump vibration.

This is optional and the necessary components must

be obtained in the field.

Drain connections should be provided at all low points

to permite complete drainage of liquid cooler and pip-

ing system.

A small valve or valves should be installed at the highest

point or points in the chilled liquid piping to allow any

trapped air to be purged. Vent and drain connections

should be extended beyond the insulation to make them

accessible.

Two typcial water piping header arrangements are

shown in Fig. 13.

The piping to and from each cooler must be designed

to suit the individual installation. It is important that the

following considerations be observed:

1. The chilled liquid piping system should be laid out

so that the circulating pump discharges directly into

the cooler. The suction for this pump should be taken

from the piping system return line and not the cooler.

2. The inlet and outlet cooler liquid connection sizes

are given on page 9.

3. A strainer, preferably 40 mesh,

MUST

be installed

in the cooler inlet line just ahead of each cooler.

4. All chilled liquid piping should be thoroughly flushed

to free it from foreign material before the system is

placed into operation. Use care not to flush any for-

eign material into or through the cooler.