YORK INTERNATIONAL

20

REMOVING THE IMPELLER (HF COMPRESSORS)

1. Before removing the impeller, measure and record

the following. (See Fig. 27) Position compressor so

that it is sitting on the correct horizontal plane to

assure correct readings

a. Impeller rim Runout (Design 0.003" Maximum)

b. Impeller eye Runout (Design 0.002" Maximum)

c. High Speed Axial thrust (Design 0.009"

to 0.020")

d. Low Speed Axial Thrust (Design 0.011"

to 0.019")

2. Install the gear locking tool on the low-speed shaft.

(See Fig. 52)

3. Remove the cap screw from the impeller.

Install Puller Plate and Puller Tool, found in the tool

kit, onto the impeller. Apply a wrench to the puller

to remove the impeller clamping color.

Considerable torque will have to be

applied to the wrench in order to re-

move the impeller-clamping collar.

REMOVING BALANCE PISTON SEAL AND DIFFUSER

PLATE

1. Remove the (3) socket head cap screws (shoulder

bolts) that fasten the balance piston retainer and

balance piston seal the to diffuser plate. (See Fig.

32 and 33)

2. Remove (2) of the (6) cap screws that secure the

diffuser plate to the bearing housing. Insert guide

pins where cap screws were removed. Loosen the

(4) remaining cap screws. (See Fig. 34) Insert jack-

ing screws into holes to loosen diffuser plate from

bearing housing.

3. Insert eyebolts from tool kit into jacking holes and

use proper rigging methods to lift diffuser plate from

compressor. Also remove o-ring from back of dif-

fuser plate.

Original design balance piston seal on

HA, HB, and HD style compressors

were equipped with (8) coil springs.

Current design on these compressors

use (16) coil springs. On the HF style

compressor the balance piston seal

uses a flat spring washer in place of

the coil springs. (See Fig. 35 - HF style

Balance Piston Seal Assembly)

2. Install the gear locking tool on the low-speed shaft.

(See Fig. 52)

3. Remove the cap screw and O-ring from the impel-

ler-clamping collar.

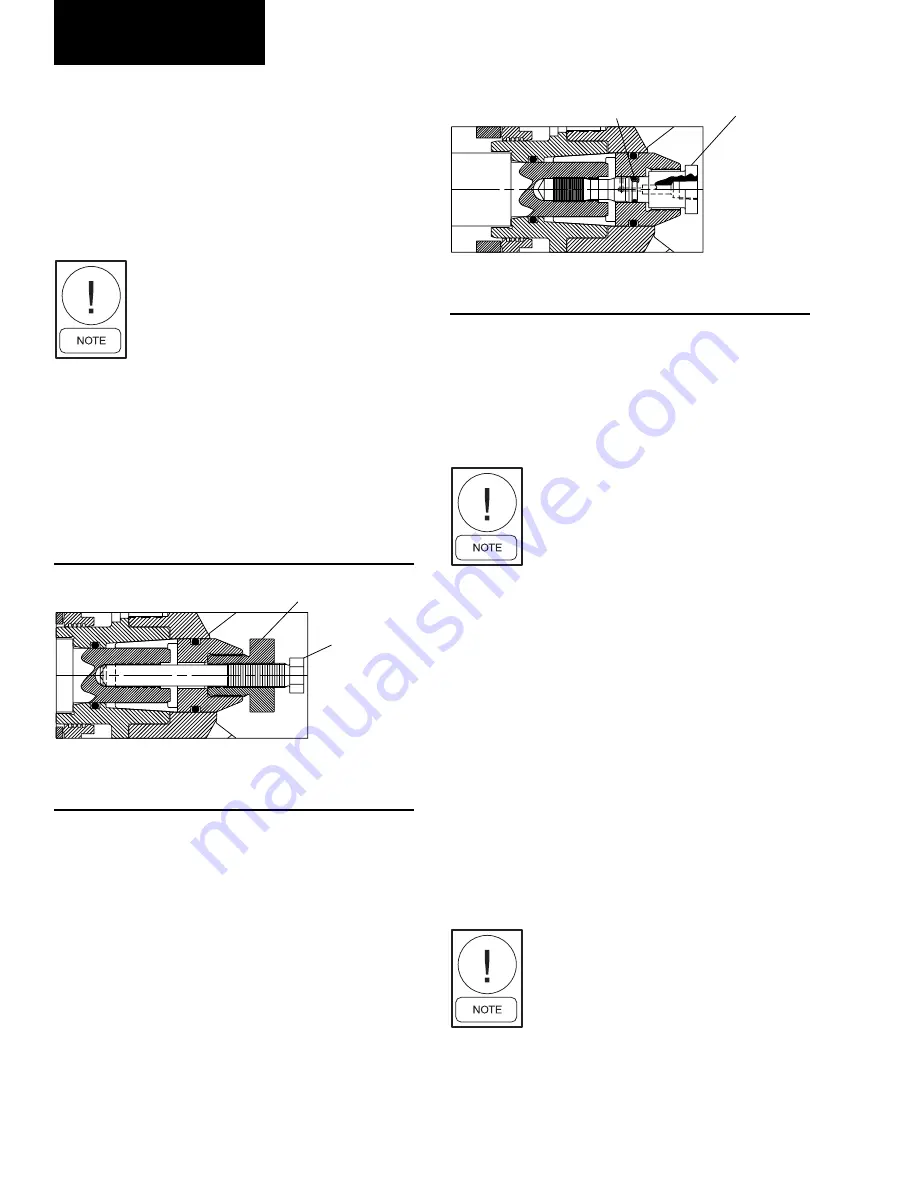

4. Mechanical Method – Install the adaptor and puller

tool, found in the tool kit, as shown in Fig. 30. Apply

a wrench to the puller tools to remove the impeller

clamping collar.

Considerable torque will have to be

applied to the wrench in order to re-

move the impeller-clamping collar.

4a. Hydraulic Method – Install the hydraulic removal

tool, found in the tool kit, as shown in Fig. 31. Con-

nect a source of hydraulic pressure (5000 PSI mini-

mum) to the head of the removal tool (1/8" NPT).

Carefully and gradually apply hydraulic pressure until

the clamping collar is loosened.

5. Pull the impeller from the high speed shaft. Use

care when removing the impeller so that the bal-

ance piston seal is not damaged.

"O" RING

HYDRAULIC

TOOL

FIG. 31 –

REMOVING THE IMPELLER

(IMPELLER SIZES 36 & 41)

LD04761

ADAPTER

PULLER TOOL

FIG. 30 –

REMOVING THE IMPELLER

(IMPELLER SIZES 36 & 41)

LD04760

Compressor Service