YORK INTERNATIONAL

42

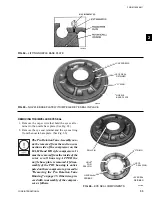

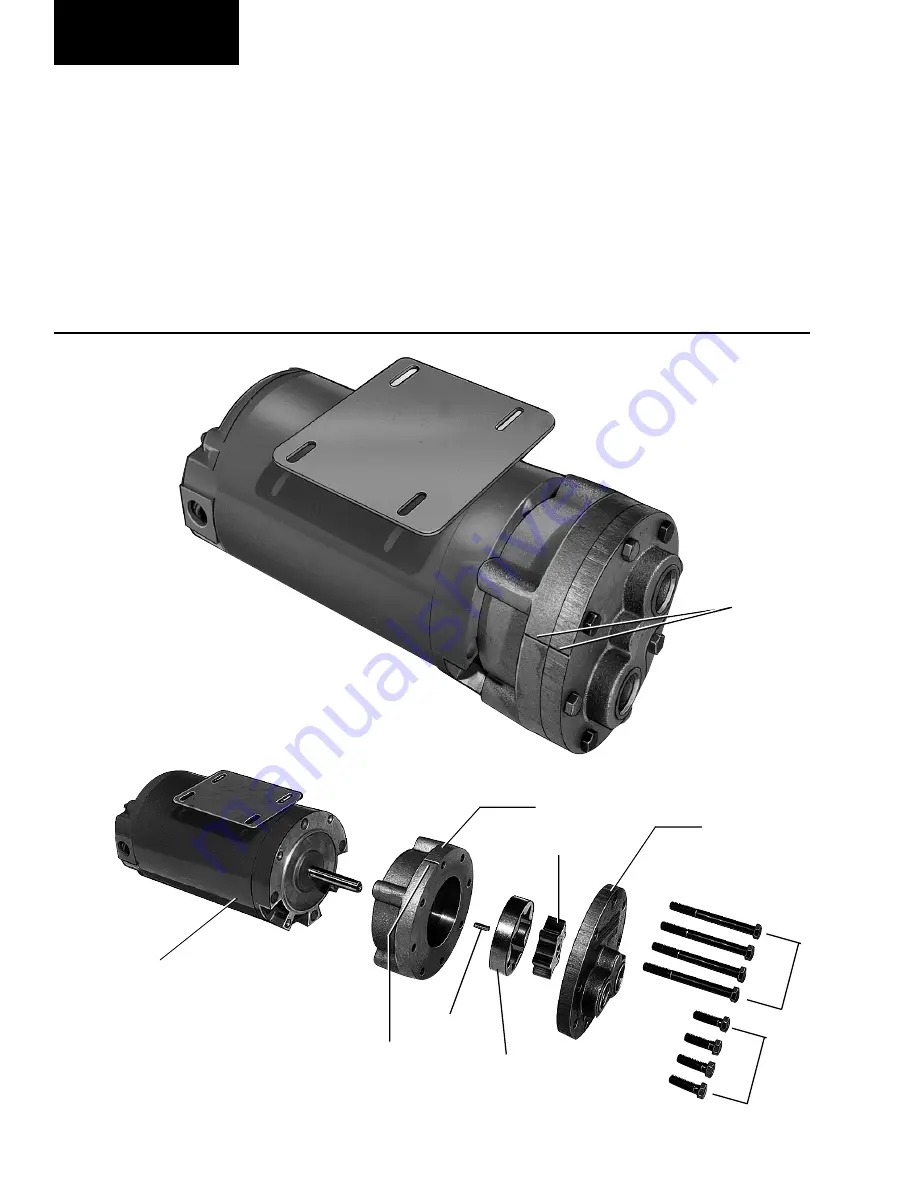

FIG. 78 –

COMPLETE PUMP AND MOTOR ASSEMBLY

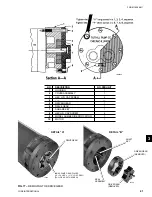

REASSEMBLING OIL PUMP ASSEMBLY

INTO OIL SUMP

(REFER TO FIG. 76)

Before assembling oil pump into oil sump pump, clean

the oil sump with approved solvent, using the utmost

care to eliminate all dirt.

1. Replace oil sump cover gasket with a new one.

Lubricate gasket with YORK refrigerant oil and

graphite.

2. Assemble the gasket and the oil pump and sump

cover assembly to oil sump using the (16) 5/8" hex

nuts. Tighten nuts using the alternating tightening

method. Torque to 155 ft. lbs.

3. Reconnect all electrical leads to fusite connection

on sump cover. Reconnect oil lines. Reconnect

transducers.

4. Charge oil into oil sump. See “Operating Instruc-

tions”, Form 160.49-O1. Be sure oil is compatible

with refrigerant being used.

5. Make sure there are no leaks around the cover and

connections.

15758

MATCH

MARK

15757

“X”

“Y”

PUMP MOTOR

MATCH MARK

PUMP HOUSING

KEY

DRIVEN GEAR

DRIVE GEAR

PUMP

COVER

Oil Pump Service