FORM 160.49-M1

5

YORK INTERNATIONAL

SECTION 1

GENERAL

GENERAL DESCRIPTION

These compressors are applied to YORK Model YK

Centrifugal Liquid Chillers.

The compressor is a single-stage centrifugal type pow-

ered by an open-drive electric motor. The casing is fully

accessible with vertical circular joints and fabricated of

close-grain cast iron. The complete operating assembly

is removable from the compressor scroll housing. Com-

pressor castings are designed for 300 PSIG working

pressure and hydrostatically pressure tested at 900 PSIG.

The rotor assembly consists of a heat-treated alloy steel

drive shaft with a lightweight, high strength, cast alumi-

num, fully shrouded impeller. The impeller is designed

for balanced thrust and is dynamically balanced and

overspeed tested for smooth, vibration-free operation.

The insert type journal bearings are fabricated of alu-

minum alloy and are precision bored and axially grooved.

Thrust bearings are of the deflection-pad type design.

The specially engineered, single helical gears with

crowned teeth are designed so that more than one tooth

is in contact at all times to provide even distribution of

compressor load and quiet operation. Gears are inte-

grally assembled in the compressor rotor support and

are film lubricated. Each shaft is individually mounted

in its own journal and thrust bearings.

The open-drive compressor shaft seal consists of a

spring-loaded, precision carbon ring, high-temperature

elastomer “O” ring static seal, and a stress-relieved,

precision lapped collar. The seal features a small face

area and low rubbing speed. It provides an efficient seal

under high pressure conditions. The seal is oil-flooded

at all times and is pressure-lubricated during compres-

sor operation.

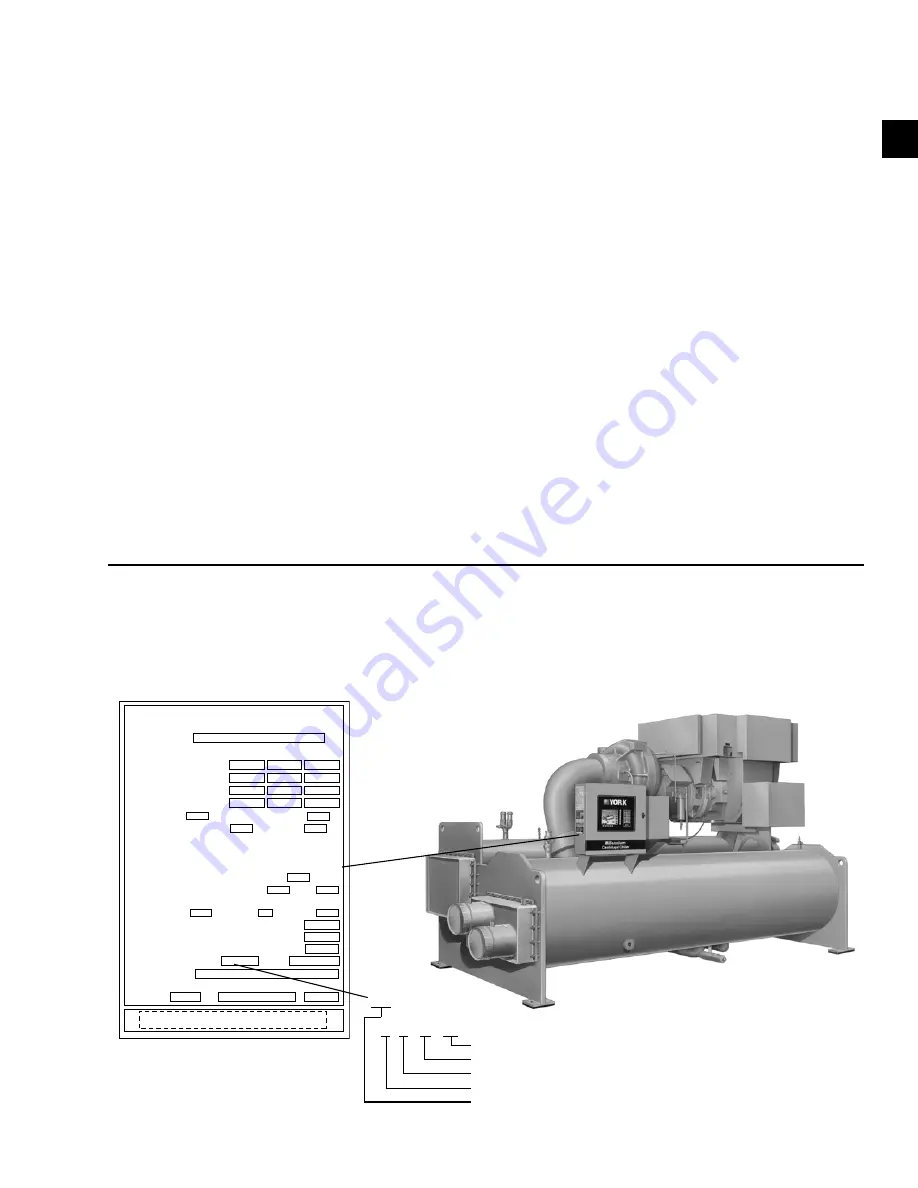

NOMENCLATURE

COMPRESSOR IDENTIFICATION

Each compressor is identified by nomenclature as shown.

The nomenclature is printed on a data plate which is

located on the side of the unit control panel. (See Fig. 1)

When contacting the factory or ordering renewal parts,

include the complete compressor model and serial num-

ber. Be sure these numbers are copied accurately.

29420A

YD H A 65

L

H

A

65

Impeller Size - 36, 41, 46, 50, 57, 61, 65, 73, 81, 90

Design Level (A - D)

High Pressure Refrigerant Compressor

Open-Drive

Close-Coupled D Flange Motor

YORK CODEPAK

™

®

LIQUID CHILLING SYSTEM

UNIT MODEL

REFRIG. DWP. PSIG:

LIQUID DWP. PSIG:

NO. OF PASSES:

SHELL TEST PRESS. PSIG:

REFRIGERANT REFRIG. CHARGE LBS.

CHARGED: FACTORY

FIELD

STARTER SUPPLIED BY: FACTORY FIELD

FIELD SUPPLY:

VOLTS

PHASE

HERTZ

MIN. CIRCUIT AMPACITY

MAX. DUAL ELEMENT FUSE AMPS

MAX. CIRCUIT BREAKER AMPS

COMPRESSOR: MODEL

CODE

SERIAL NO.

HP

VOLTS-PHASE-HZ

FLA

OIL PUMP

CHARGE WITH YORK REFRIGERANT OIL

SEE STARTER NAMEPLATE AND CONTROL

PANEL NAMEPLATE FOR ELECTRICAL DATA

COOLER

CLG.

COND.

H.R.

COND.

FOR REMOTE STARTER SEE YORK STD. R

LD04750

FIG. 1 –

COMPRESSOR IDENTIFICATION

1