FORM 155.32-ICOM2.EN.UL

SECTION 7 – MAINTENANCE

ISSUE DATE:1/10/2018

JOHNSON CONTROLS

140

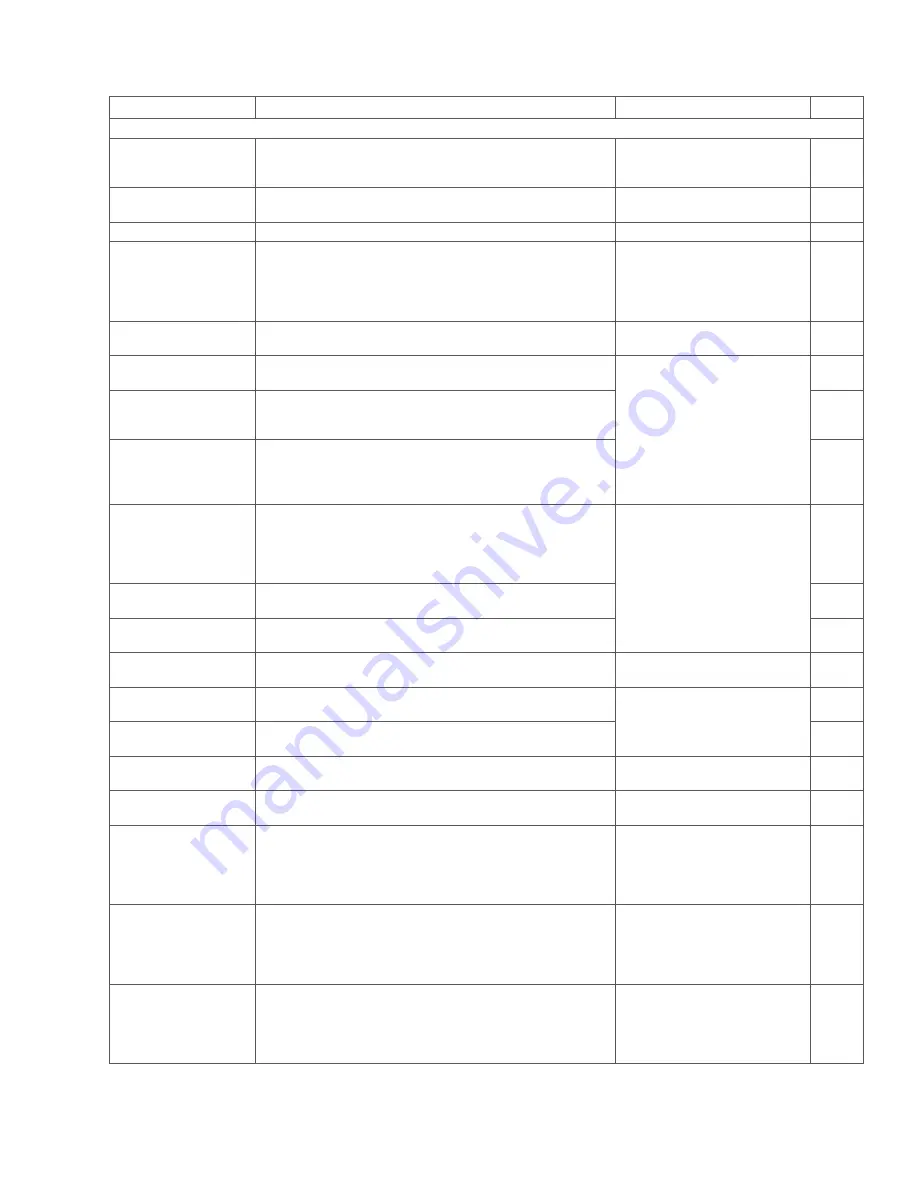

Table 38 -

Maintenance and Inspection

TASK

CONTENTS

FREQUENCY

SCOPE

C = Customer, S = Johnson Controls Service

Recording of operation

data

Collect the operation data (Refer to

Start-up and Pre-Startup

Checklist 155.31-CL1

) and check the data with the data

collected during the factory test.

Weekly

C

Check of liquid level

Abnormal Solution and Refrigerant Levels on page 166

.

Check the liquid level at each part.

Daily

C

Refining of refrigerant

. Refine the refrigerant.

every 2-3 weeks

S

Manual purging from

purging tank

. Manually purge non-

condensable gas from the purging tank.

Since, the machine has an

automatic purge system, perform a

purge once at the beginning of

each season every year OR once

every 2-3 months.

S

Manual purging from

absorber

See

. Manually purge non-

condensable gas from the absorber.

every 2-3 months

S

Replacement of oil in

vacuum pump

Replace the oil in the vacuum pump.

monthly

C

Check of Vacuum Pump

After the replacement of the lubricant oil for the vacuum pump, be

sure to pull the pulley belt and check the smooth motion of the

pulley.

C

Appearance check

Check the outside of the unit for damage (example, leakage for

chilled/hot water and cooling water, rusting, or other noted

damage). Check the solution pump and refrigerant pump for

abnormal sounds and vibration.

C

Measurement of

insulation resistance of

electric devices

Measure the insulation resistance of the main circuit and motors

(solution pump, refrigerant pump) mainly to check for lowering of

insulation. When measuring the insulation resistance, be sure to

disconnect the wires of the temperature controller and other wires

that could interfere with this testing.

yearly

S

Check of terminals for

looseness

Check each terminal in the control panel for looseness.

S

Check of operation of

control panel

Check the operation of the control panel to prevent troubles

caused by malfunction of the control panel.

S

Check of capacity of

purge unit

. Check the capacity of the

purge unit.

monthly

S

Check of leakage through

purge solenoid valves

By measuring vacuum down speed, check for leakage through

purge solenoid valves.

yearly

S

Overhaul check of purge

solenoid valves

Perform overhaul of purge solenoid valves.

S

Check of airtightness

Measure the quantity of

non-condensable

gas discharged from the

vacuum pump.

every 2-3 months

S

Check continuity of

protective bonding circuit

Check continuity of protective bonding circuit.

yearly

S

Analysis of quality of

chilled/hot water, and

cooling water

Reliable water treatment companies are available in most larger

cities to supply a water treating process which will greatly reduce

the corrosive and scale forming properties of almost any type of

water. Be sure to request the first analysis within one month after

the test operation is started.

every 2-3 months

C

Check of quantity of

solution and refrigerant

The solution is not consumed, but the refrigerant is minimally

discharged each time purging is performed. If the quantity of the

refrigerant becomes insufficient, the condensation preventive

function does not work normally. Accordingly, check the quantity of

the refrigerant.

yearly

(during operation

at 100%)

S

Disassembly inspection

and cleaning of solution

pump and refrigerant

pump

Sleeve bearings are used for the solution pump and refrigerant

pump, and they are normally lubricated with water solution of LiBr

and refrigerant. Since excessive wear can cause a pump problem,

disassemble and inspect the bearings. The internal strainer must

also be cleaned.

2-3 years or

8,000 hrs

S