FORM 155.32-ICOM2.EN.UL

SECTION 7 – MAINTENANCE

ISSUE DATE:1/10/2018

JOHNSON CONTROLS

155

Dry Storage

Dry storage involves draining the water from the tubes. It is most often used when the unit

is installed in an outdoor location.

Condition around the chiller-heater:

• During the heating operation period, there is concern of cooling water freezing.

• Cooling tower is installed at the same level (height) of the chiller-heater.

• Lining pipe is used for the cooling water piping system.

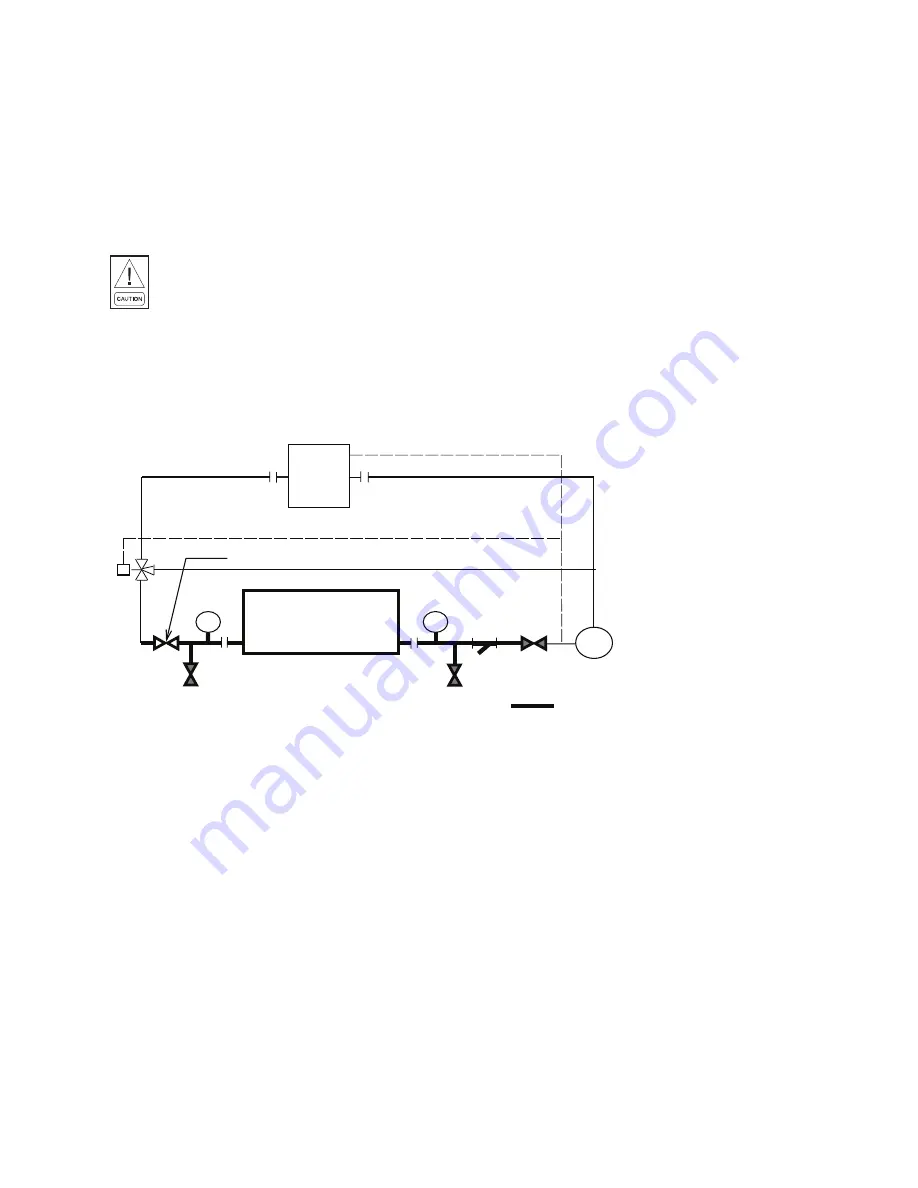

Figure 72 -

Dry Storage During Heating Operation Period

Work Procedure

1. Drain all of the cooling water from the absorber and the

condenser

.

2. Flow the clean water from the higher location than the chiller-heater, and then feed

the clean water continuously and clean the tubes well.

3. Fill absorber and condenser with clean water.

4. Circulate it with the cooling water pump for 30 minutes to 1 hour.

5. Drain all of the cooling water from the absorber and the condenser.

6. Dry inside of each water chamber and heat transfer tube well.

7. Keep this condition during heating operation period.

CAUTION: Do NOT leave the tubes in absorber and condenser as is after simply drain-

ing the remained cooling water. If you do, the heat transfer tubes will be at high risk of

corrosion and rusty water (red rust) generation.

LD20942

Start/stop signal for cooling tower fan

Cooling

Tower

Open/close signal for three way valve

Thermometer

Chiller-Heater

Thermometer

Strainer

Close

Cooling water pump

Filled with water

P

T

T

Close

Drain valve

Close

Drain valve

Open slightly