FORM 155.32-ICOM2.EN.UL

SECTION 3 - HANDLING, STORAGE, INSTALLATION AND REASSEMBLY

ISSUE DATE:1/10/2018

JOHNSON CONTROLS

35

• Drain port

• Seat for measuring draft pressure

• Combustion chamber inspection window

• Combustion monitor

At the points where the flue and smokestack penetrate a wall or ceiling, use a heat-

resisting, fire-proof construction (nonflammable material, such as concrete.

Provide the flue with sufficient support taking its thermal expansion into account. In

addition, provide the flue with a suitable vibration-proof measure. Make sure that the flue

does not apply load to the chiller-heater.

If there is noise concern, consider installing a flue muffler or a smokestack.

Keep the flue openings significantly away from the air inlets of the cooling tower and air

conditioner so that the flue gas does not enter cooling tower, etc. In particular, when the

chiller-heater uses a fuel containing a considerable amount of sulfur (e.g., kerosene oil or a

heavy oil), be sure to install a protective shield or prevent installation of the chiller-heater

and other equipment in the same section enclosed by walls. Make the flue free from entry

of rainwater, snow, etc. In addition, the flue should be constructed so that the ventilation is

not prevented by winds, etc.

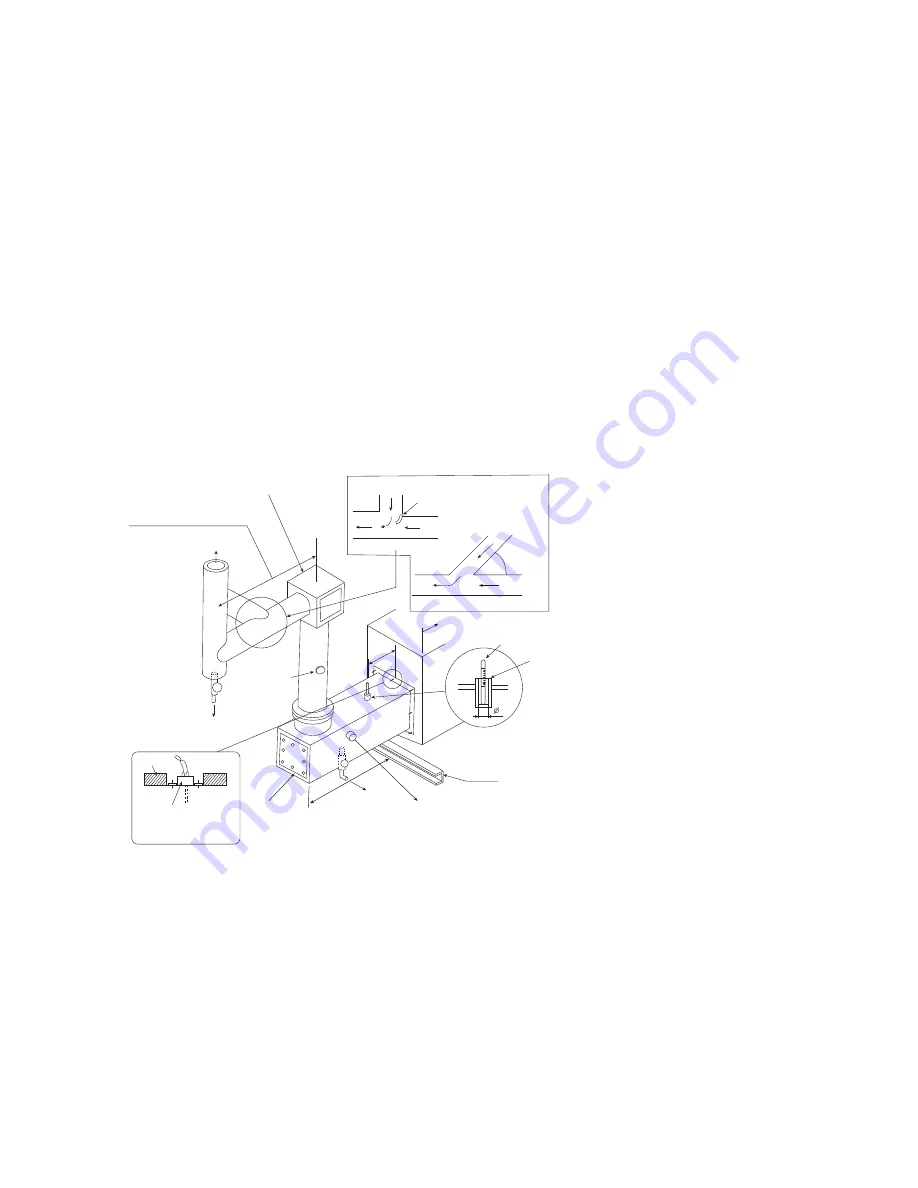

Figure 14 -

Exhaust Gas Flue Diagram

NOTE:

1. The smokestacks box (option) and the flue and instruments after the points of con-

nection with the flue are outside the scope of delivery.

2. Insulate the flue on the basis of 662 °F. to protect from possible burning.

3. Bolts, nuts and packing for fixing the flue are out of scope of delivery. It is the cus-

tomers responsibility to provide these items.

4. For dimensions of the flue connections,

see the Delivery Specifications

in

in this manual.

5. Do not apply flue weight to the chiller-heater.

6.

When insulating the chiller-heater, make sure the soot and dust monitor, draft pres-

sure measuring seat, and the thermometer can be removed and refitted freely.

LD27591

Draft regulator

(Install when the crosscut of gas duct exceeds 3 m

Or the draft power is 49 Pa or more.)

Crosscut should be 3 m or less.

(See note 18.)

To smokestack

Soot and dust monitor

Drain vent

Hot insulation

Exhaust gas temperature relay

Do not embed the relay in the

heat insulation

200

Combustion

chamber inspection

window

Provide the drain port

in the bottom.

To drainage ditch

Drain measuring seat

(Rc 1/2 female)

Set pressure in the range 0 to -49 Pa

Base

Exhaust gas

thermometer

Approximately

10

Exhaust gas

Maximum

45 degrees

Exhaust gas

Arrangement for multiple flue

Exhaust gas

Straightening vane

Exhaust gas

Max

imu

m

1 m

Fix the thermometer

with nonflammable

material (example, asbestos)

Thermometer (out of scope)

Chiller-heater high temperature generator

Arrangement for multiple flue